Stable white light OLED (Organic Light Emitting Diode) of multi-light-emitting-layer mixed parent structure without transmission layer

A technology of light-emitting layer and transmission layer, applied in the field of stable white light OLED, can solve the problems of reducing the luminous efficiency and spectral stability of the device, increasing the difficulty of carrier transmission, and increasing the difficulty of manufacturing, so as to avoid excessive turn-on voltage, Increase the coverage and the effect of small CIE coordinate offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

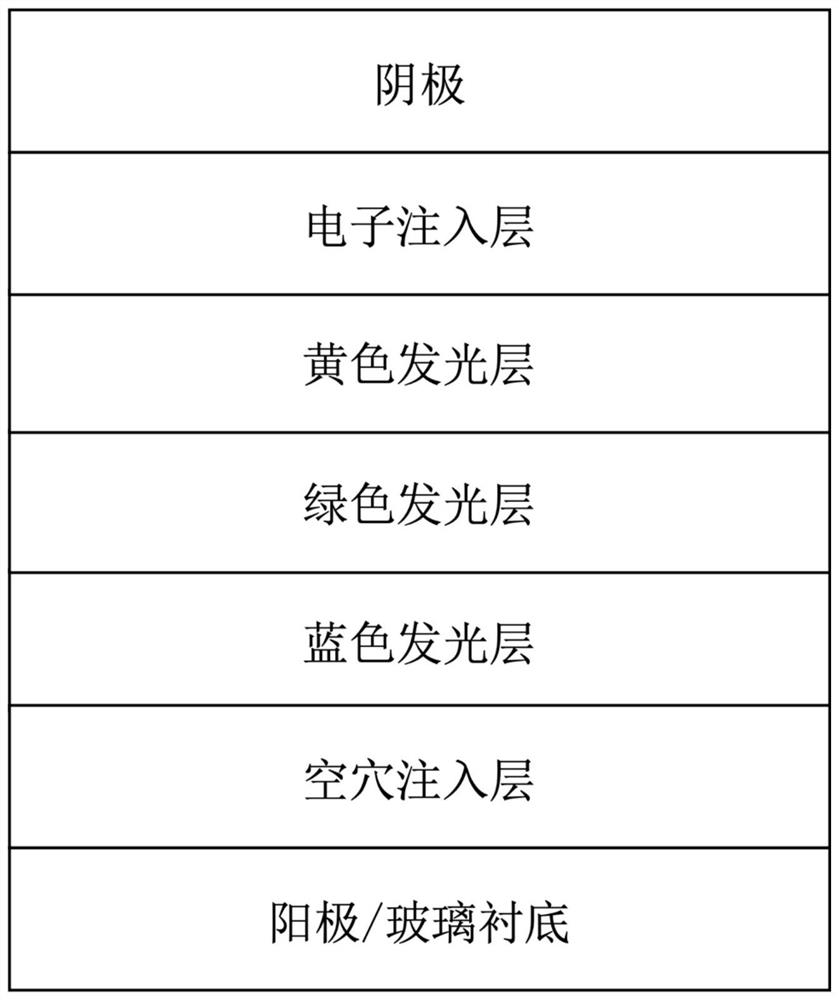

[0036] The preparation of a stable white light OLED with a mixed matrix structure of multiple light-emitting layers without the transport layer includes the following steps:

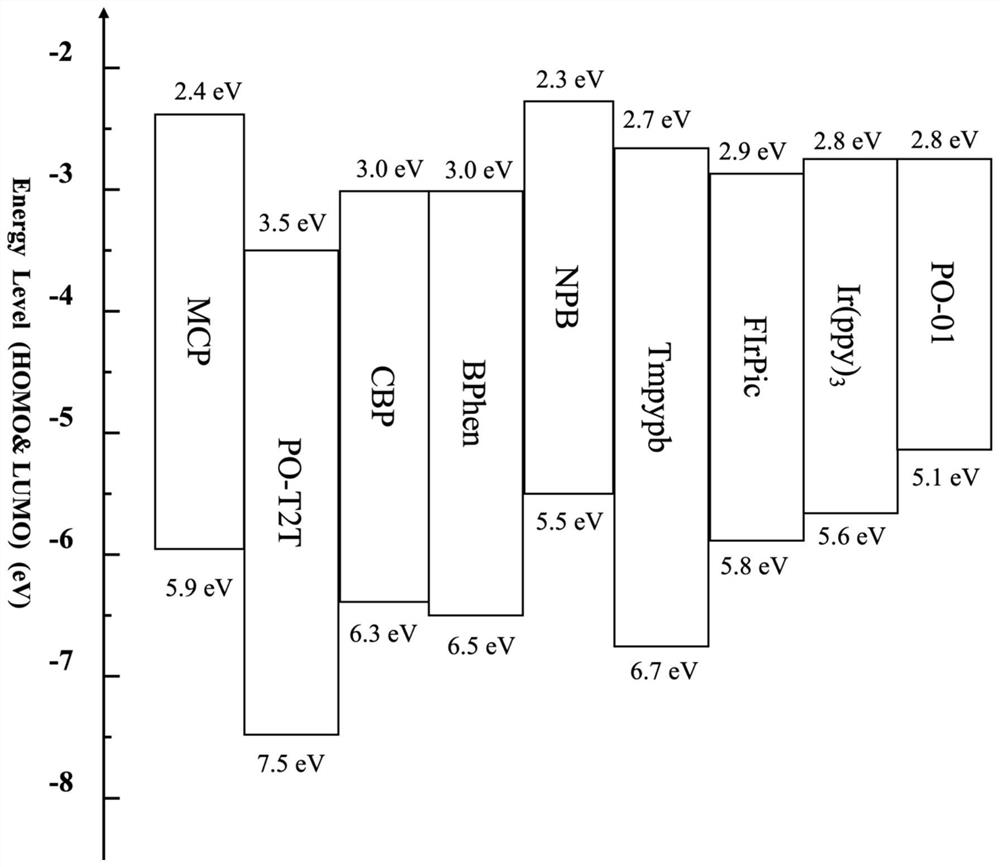

[0037] (1) The device structure is: ITO / MoO 3 (2nm) / MCP:PO-T2T:8wt%FIrPic(25nm) / CBP:BPhen:Ir(ppy) 3 (2:1, 8wt%, 25nm) / TCTA:BCP:8wt%PO-01(25nm) / Liq(1nm) / Al.

[0038] (2) Use acetone, ethanol, and deionized water to repeatedly clean the front and back sides of the ITO glass substrate for 10 minutes, followed by ultrasonic treatment in each of the above three solutions for 10 minutes in turn. The purpose is to remove dust and stains on the glass substrate. Then, the ITO glass substrate was taken out and dried, and then subjected to ultraviolet treatment for 10 min, in order to improve the surface work function of ITO.

[0039] (3) The treated ITO substrate is placed in a multi-source organic molecular vapor deposition system for evaporation, and the organic materials and metal materials used are placed i...

Embodiment 2

[0045] The preparation of a stable white light OLED with a mixed matrix structure of multiple light-emitting layers without the transport layer includes the following steps:

[0046] (1) The device structure is: ITO / MoO 3 (2nm) / MCP:PO-T2T:8wt%FIrPic(25nm) / CBP:BPhen:Ir(ppy) 3 (2:1,8wt%,25nm) / TCTA:BCP:PO-01(1:2,8wt%,25nm) / NPB:TmPyPB:8wt%Ir(piq) 2 (acac)(25nm) / Liq(1nm) / Al.

[0047] (2) Use acetone, ethanol, and deionized water to repeatedly clean the front and back sides of the ITO glass substrate for 10 minutes, followed by ultrasonic treatment in each of the above three solutions for 10 minutes in turn. The purpose is to remove dust and stains on the glass substrate. Then, the ITO glass substrate was taken out and dried, and then subjected to ultraviolet treatment for 10 min, in order to improve the surface work function of ITO.

[0048] (3) The treated ITO substrate is placed in a multi-source organic molecular vapor deposition system for evaporation, and the organic mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com