High performance organic electroluminescent device and preparation method thereof

An electroluminescent device, high-performance technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the drift of luminous intensity of light-emitting units, low CRI color coordinate CIE, preparation process and cost constraints, etc. problem, achieve the effect of reducing the external quantum efficiency of the device and the roll-off of power efficiency, reducing the manufacturing cost and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

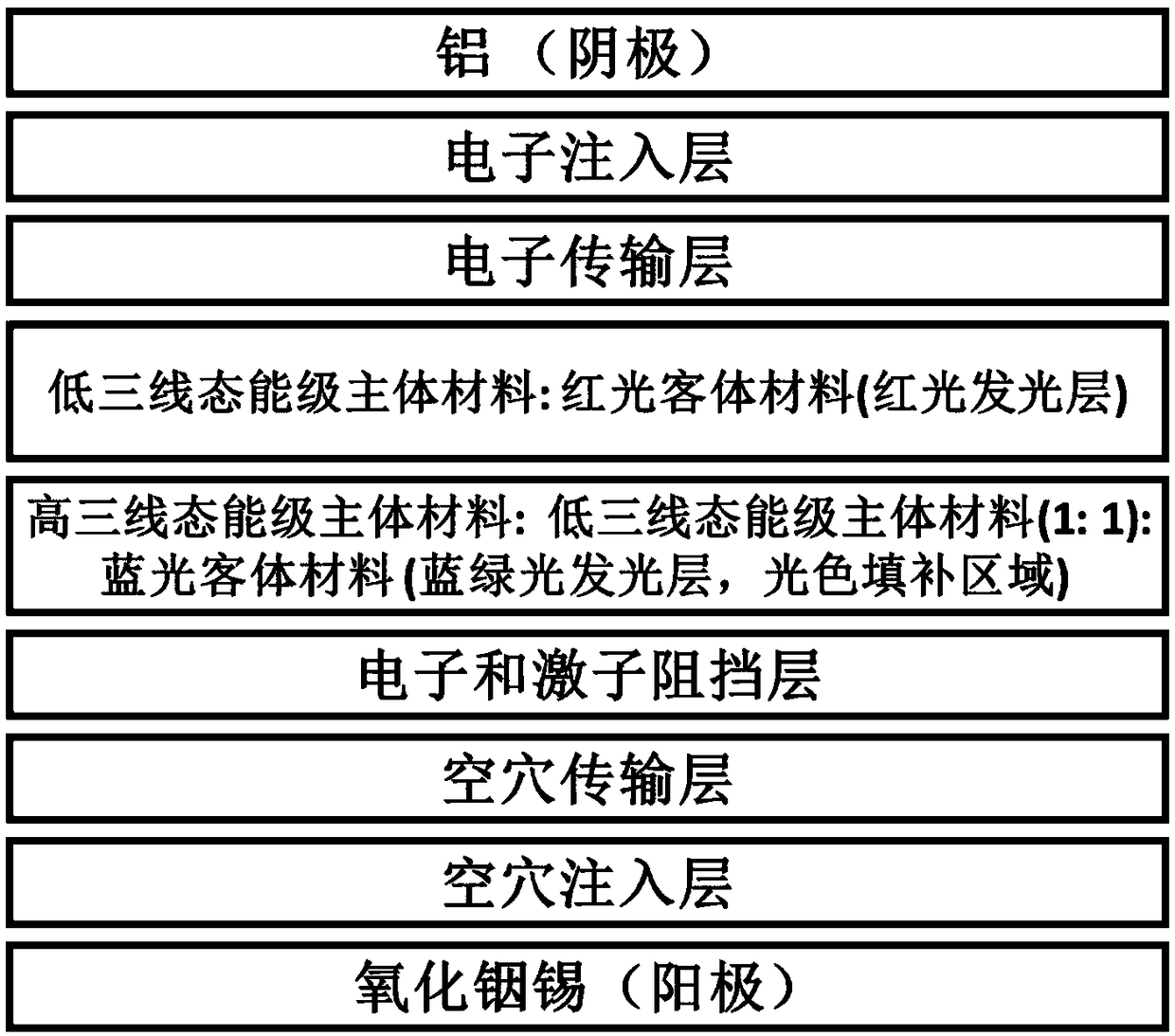

[0038] This embodiment discloses a method for preparing a high-performance organic electroluminescent device, the method comprising the following steps:

[0039] S1, ultrasonically cleaning the anode substrate, and baking until dry;

[0040] Specifically: Magnetron sputtering a layer of 80nm thick indium tin oxide (ITO) on the surface of transparent glass as the anode, followed by repeated ultrasonic cleaning three times with acetone, ethanol and deionized water, and then moved to an oven at 110°C for 20 minutes to remove Solvent and moisture remaining on the surface.

[0041] S2, treating the anode substrate with ultraviolet lamp and ozone;

[0042]Specifically, after taking out the ITO transparent conductive glass substrate, treat it with ozone for 20 minutes with an ultraviolet lamp.

[0043] S3, placing the anode substrate in the vacuum chamber, and evacuating;

[0044] Specifically, the anode substrate is taken out, placed in a chamber of a vacuum thin film deposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com