Multi-layer glass sheet made by co-drawing using the overflow downdraw fusion process

A transparent glass and inner layer technology, which is applied in glass forming, glass forming, glass manufacturing equipment, etc., can solve the problems of increasing production cost and time, and existing waste disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

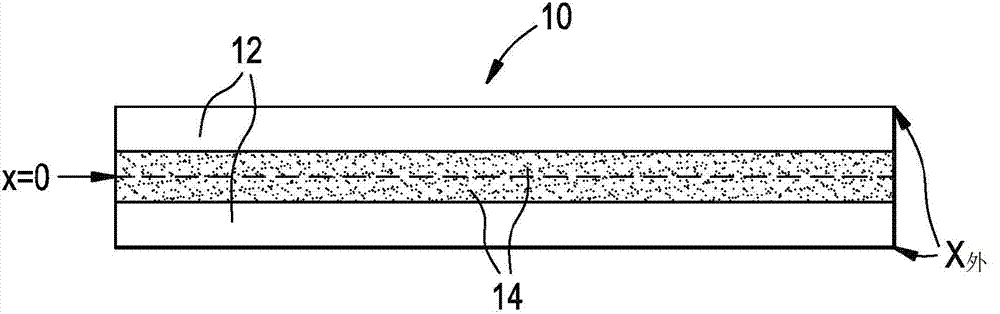

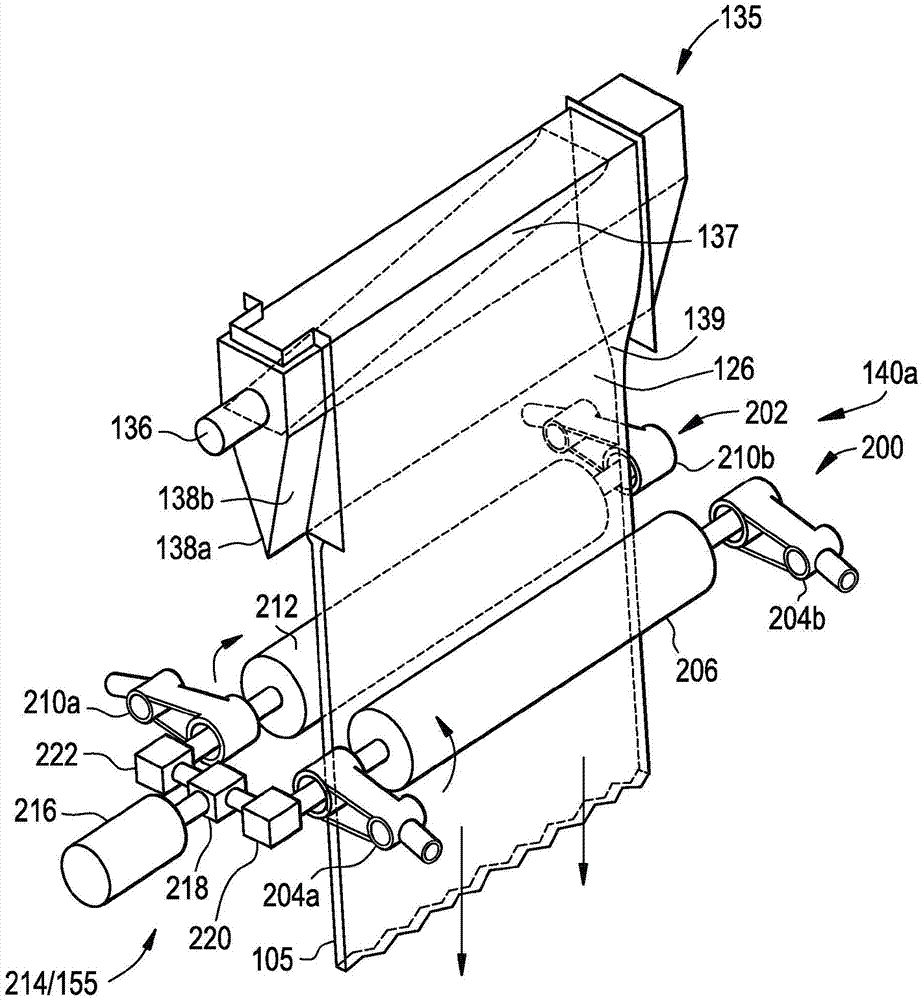

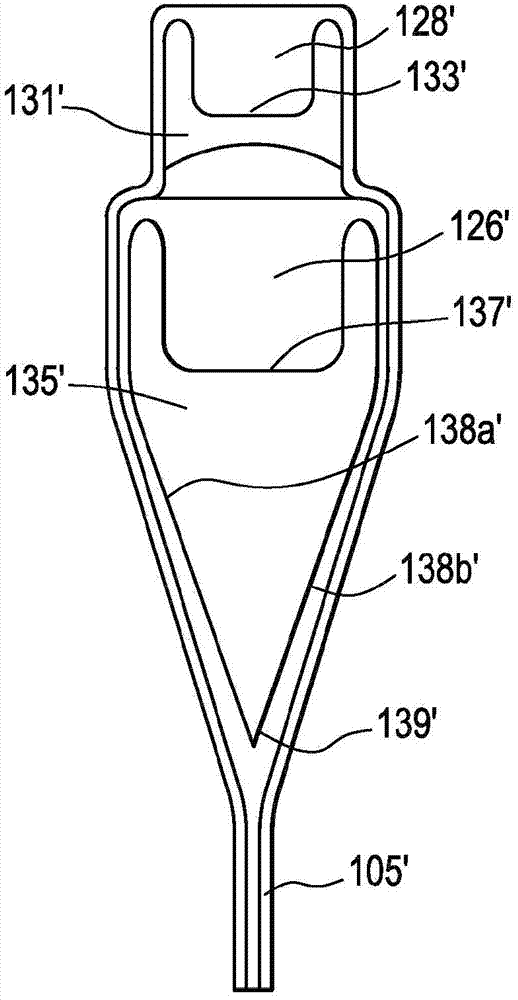

[0014] We propose a method of fabricating transparent glass sheets with compressive stress on the surface, wherein the amount of compressive stress in the glass sheet and the thickness of the compressive layer can be easily adjusted for a wide range of compositions, sizes and thicknesses.

[0015] As used herein, the term "transparent" is used to denote a solid material through which at least 80% of the radiant energy in the visible spectrum that passes through the material is transmitted, rather than absorbed or scattered by the material. Particularly preferred transparent materials include those through which at least 95% of the radiant energy in the visible spectrum that passes through the material is transmitted through the material rather than being absorbed or scattered by the material.

[0016] As used herein, the term "in situ crystallization process" means a process in which a thermal treatment regime is applied to a crystallizable formable glass in which the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com