Four-wheel drive sitting-type mini-tiller

A four-wheel-drive, micro-tillage machine technology, applied in the fields of farming machines, agricultural machinery and implements, applications, etc., can solve the problems of limb weakness and the need to rest for a few days to recover physical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with the description of the drawings and specific embodiments for further detailed description

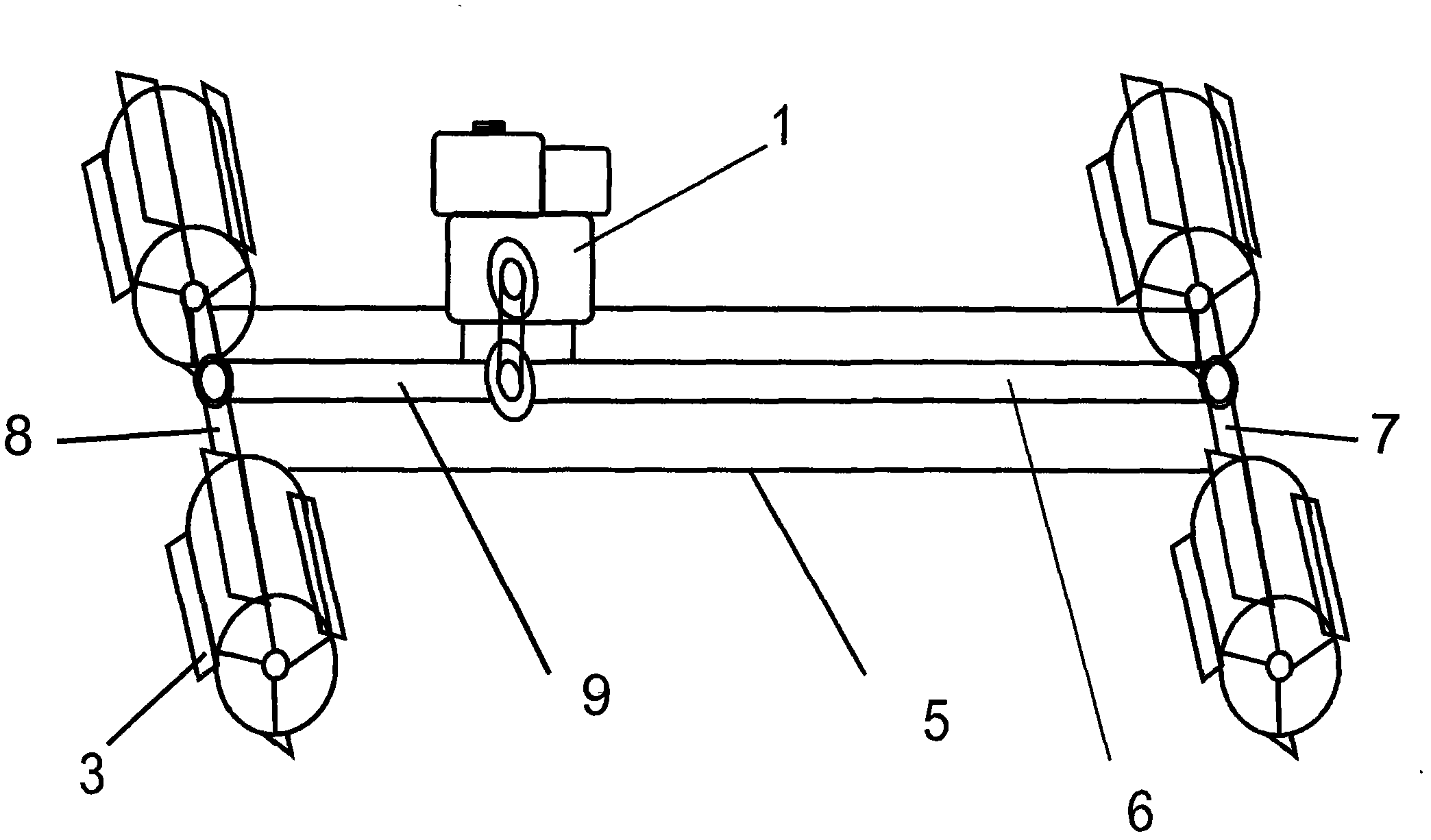

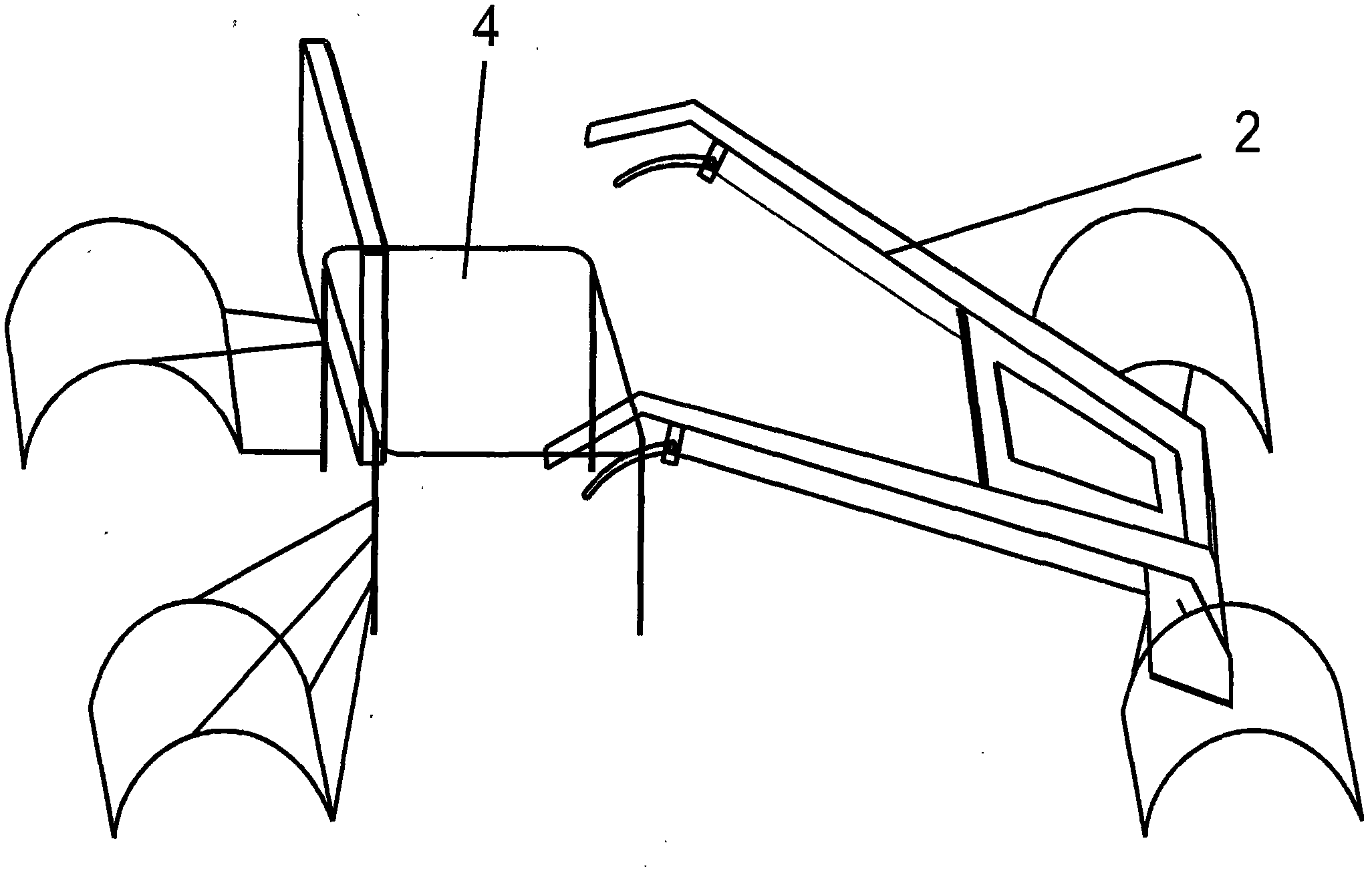

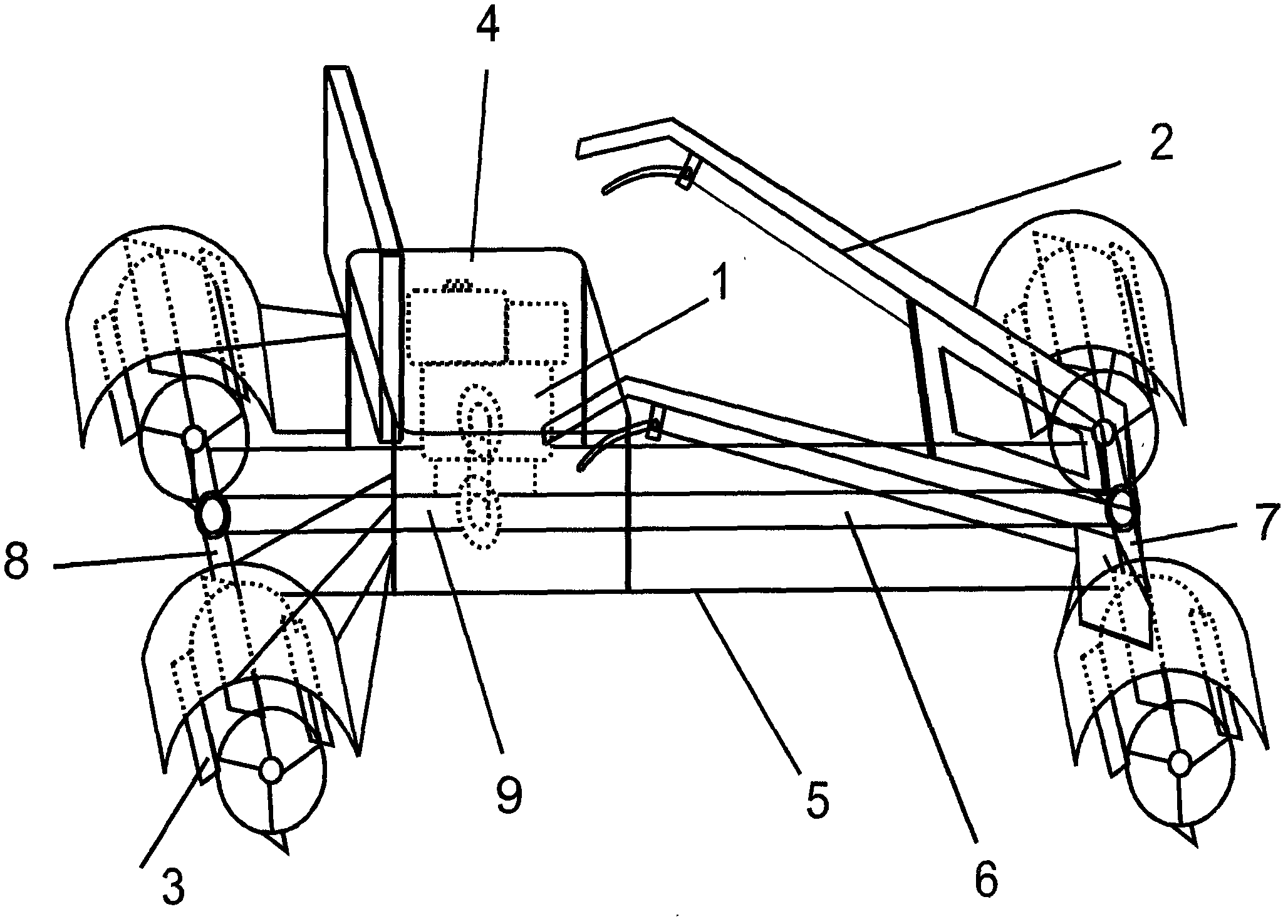

[0009] Depend on figure 1 , figure 2 , image 3 It can be seen that the four-wheel drive sit-type tiller consists of an engine 1, a handlebar 2, a rotary tiller 3, and a seat 4. There are four rotary tillers 3, which are respectively connected to the front axle 7 and the rear axle of the vehicle frame 5. 8, and be connected with front and rear power transmission shaft 6 and rear power transmission shaft 9, the seat cushion on the seat 4 is hollow, and the inside is full of air, reduces the shaking power to people when micro-cultivator plows the field. It avoids the influence of the frequent shaking of the tiller on the body of the operator. When the manipulator is working in the field, according to the depth of the paddy field, if the field is hard, choose the two rotary tillers at the back to rotate the field, and use the weight of the manipulator a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com