Electric shaver

A technology for electric razors and blades, applied in metal processing, etc., can solve the problems of small surface area of fixed blades, total shaving residue, and low efficiency, and achieve stable rotation, good veneer, and good fit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

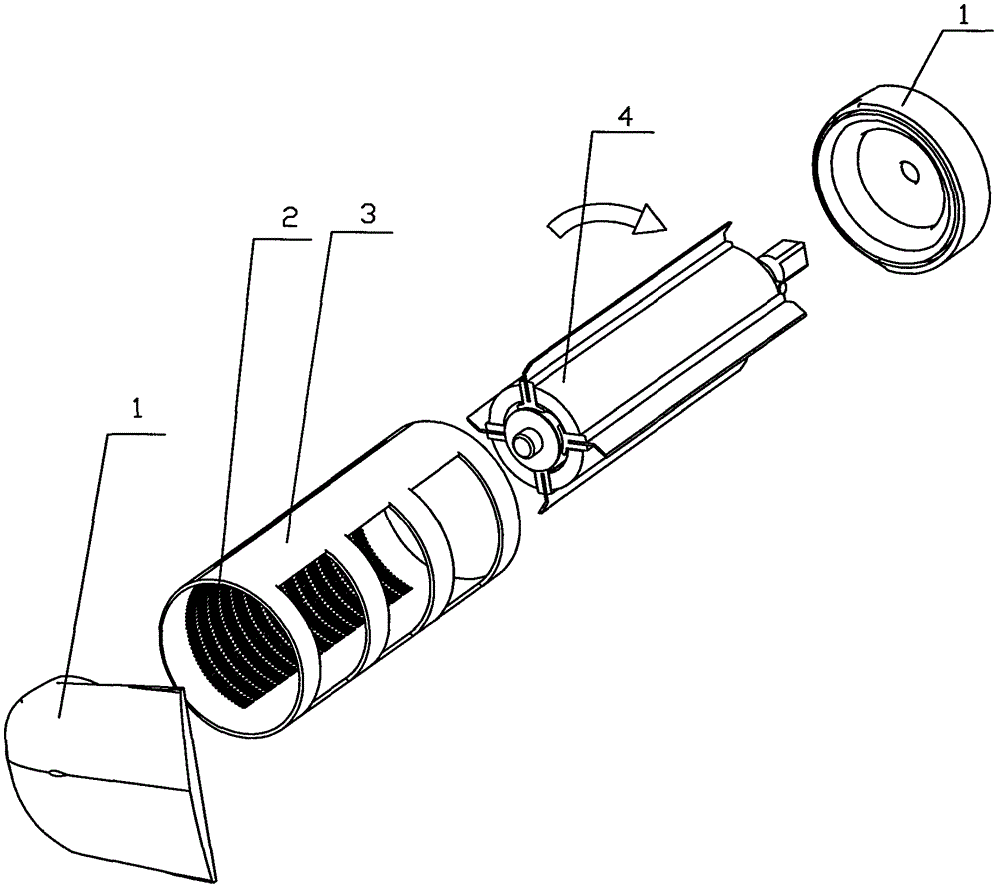

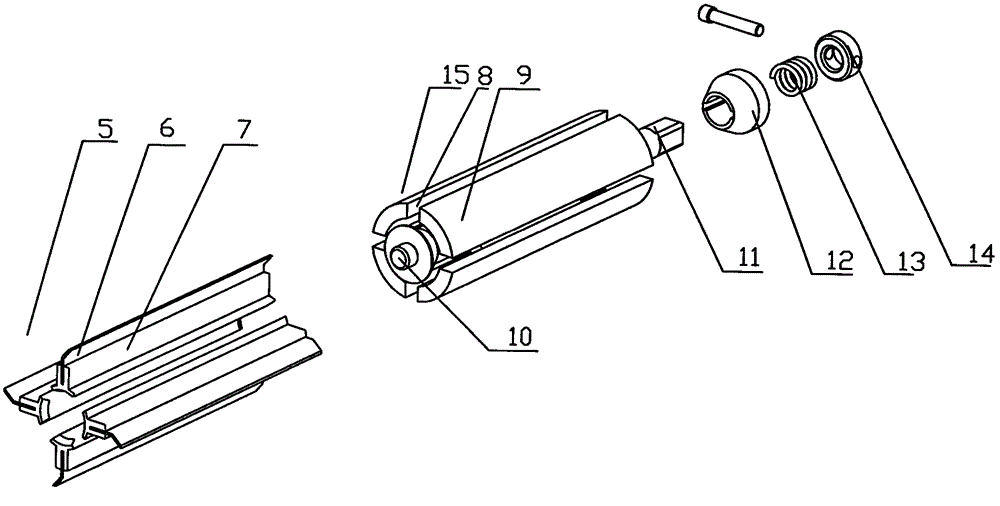

[0015] An electric shaver includes a blade body and a cutter head assembly mounted on the blade body, and a motor is installed in the blade body, such as figure 1 , 2 As shown, the cutter head assembly includes a moving knife 4 and a fixed knife 3 attached to the moving knife. The moving knife includes a knife holder 15 and a blade assembly 5 arranged on the knife holder. The blade assembly includes 4 blades 6, and the blades 6 are respectively Be fixed on its corresponding blade frame 7. Tool rest 15 is set to cylindrical, and the center of knife rest is central axis 10, and tool rest 15 is to rotate with central axis 10 as axis, and one end of the central axis of knife rest is fixed with gear 11, and gear 11 connects motor by transmission mechanism. Output shaft. The central axis of the knife rest is connected to the tile-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com