Process for producing reflective shell and reflective helmet coating reflective shell

A reflective and helmet technology, applied in helmets, helmet covers, decorative arts, etc., can solve the problems of general reflective effect, high defective rate, easy to steal, etc., to achieve the best reflective effect, improve the yield and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

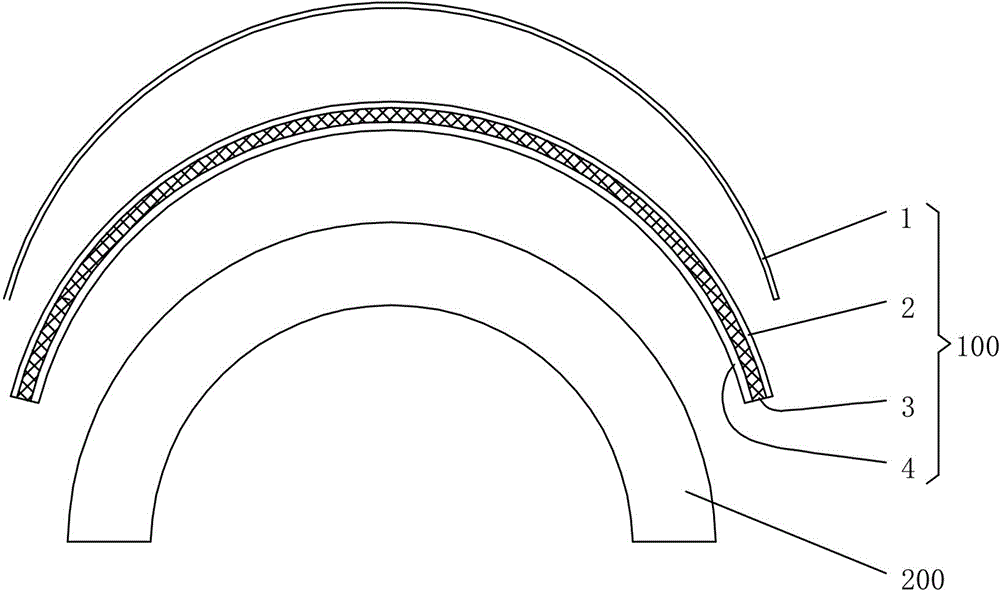

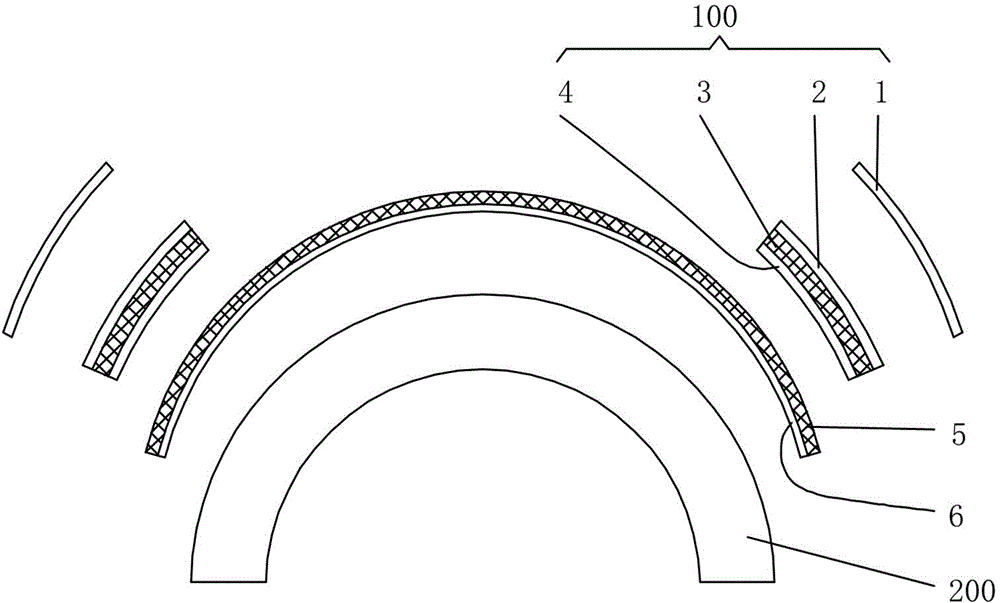

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] A production process for a reflective shell for a helmet, the steps of which are as follows:

[0024] (1) Prepare PC sheets of a certain specification; PC sheets are generally obtained from outsourcing, therefore, both sides of the PC sheet will be attached with a protective film to avoid friction and scratches caused by the PC sheet during transportation, The specific size of a piece of PC sheet in the present invention has no exact limit, this is because the size of the reflective shell made can be adjusted according to the customer's choice, and the reflective shell can be designed as a large reflective area covering the entire helmet shell, It can also be a sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com