Method of operating a motor vehicle hydraulic braking system and hydraulic braking system

A technology of motor vehicles and braking systems, applied in the direction of brakes, etc., can solve the problems of braking system failure, energy complexity, disadvantages, etc., and achieve the effects of reducing braking distance, precise control, and reducing braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

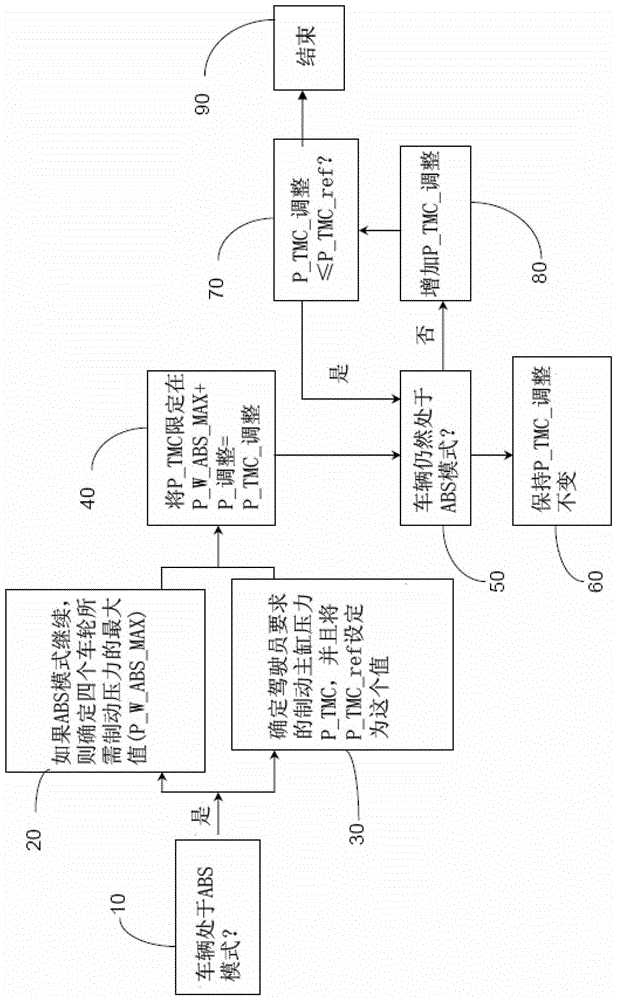

[0022] The algorithm according to the invention is executed in a known manner by the engine controller (ECU) or a suitable engine control system (eg ESC unit) as part of a background loop executed periodically (eg every 20 milliseconds).

[0023] In step 10, the operating controller receives information from a higher level or equivalent level controller (not shown in the figure) as to whether the vehicle is in ABS mode, i.e. whether the braking of at least one wheel of the vehicle needs to be reduced. power. If the vehicle is not in ABS mode, the algorithm ends immediately (not shown in the figure).

[0024] If ABS mode is present, regardless of whether ABS intervenes or not, in step 20 the required maximum brake pressure P_W_ABS_MAX is calculated for all wheels of the vehicle.

[0025] Furthermore, in step 30 , the pressure level of the master cylinder required by the driver (or the brake assist system) is queried. This value is stored in the variable P_TMC_ref.

[0026] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com