Control valve, electronically controllable brake system and method for controlling the electronically controllable brake system

A technology for controlling valves and control chambers, applied in brake control systems, control valves, air release valves, brakes, etc., can solve the problems of high cost and high technical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

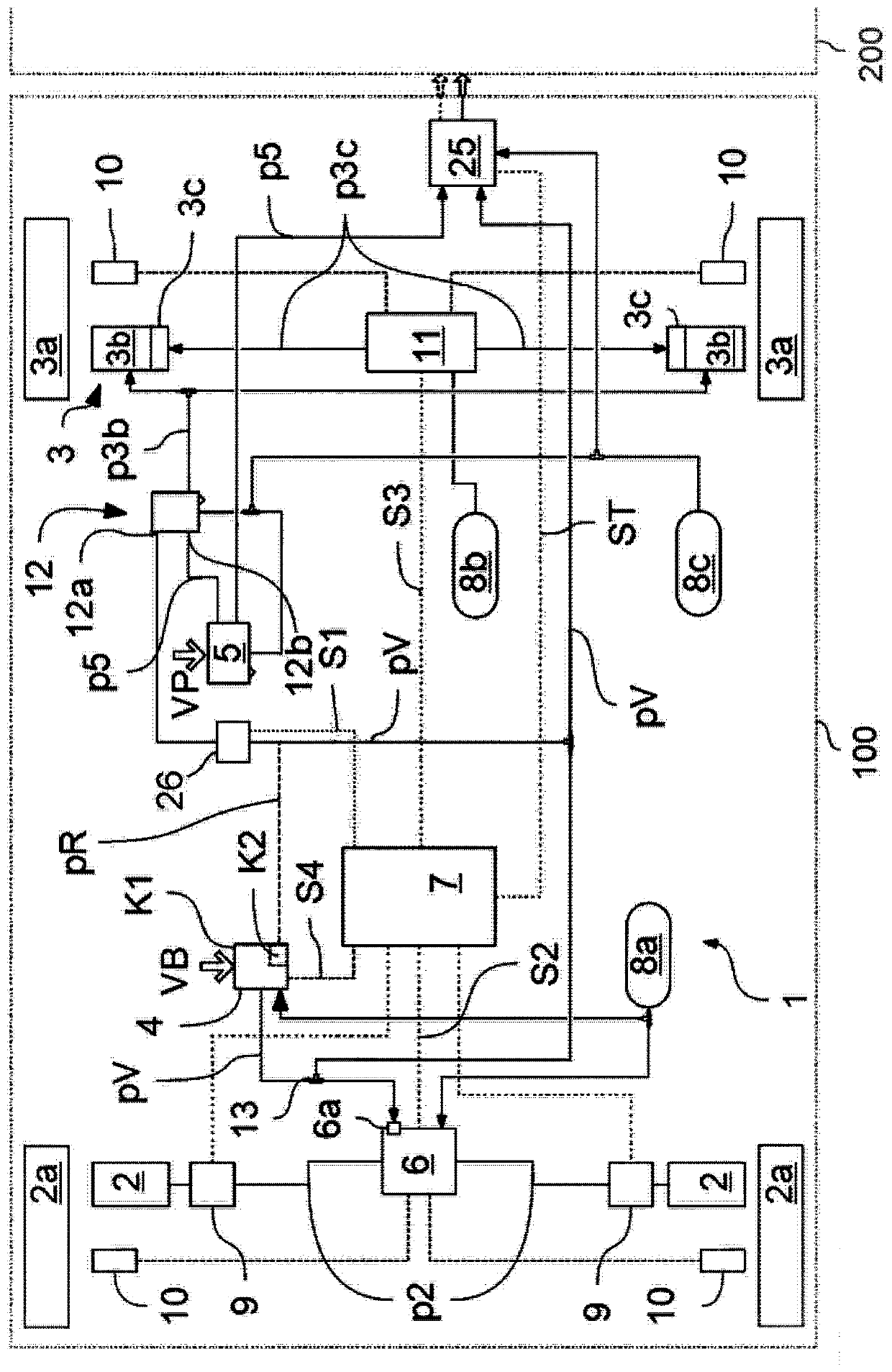

[0051] according to figure 1 A train consisting of a towing vehicle 100 and a trailer 200 hitched thereto is shown. The towing vehicle 100 has an at least partially electronically controllable dual-circuit braking system 1 , the wheel brakes 2 , 3 of the front and rear axles of which can be activated manually via the service brake valve 4 and the parking brake valve 5 . Operate to operate.

[0052] When the service brake valve 4 is actuated with a specific service brake pre-determined parameter VB, a front-axle brake pressure corresponding to this pre-determined parameter can be built up at the front axle wheel brake 2 in an electrically or pneumatically controlled manner. p2. For this purpose, the service brake control pressure pV of the front axle is transferred from the pneumatic part of the service brake valve 4 to the front axle pressure regulation module via the pneumatic redundant connection 6a, depending on the magnitude of the service brake presetting parameter VB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com