Shock-free wrapping tape type unlocking separation mechanism

A separation mechanism and wrapping technology, applied in the field of aerospace, can solve the problems of large shock response, small load, high production cost, etc., and achieve the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

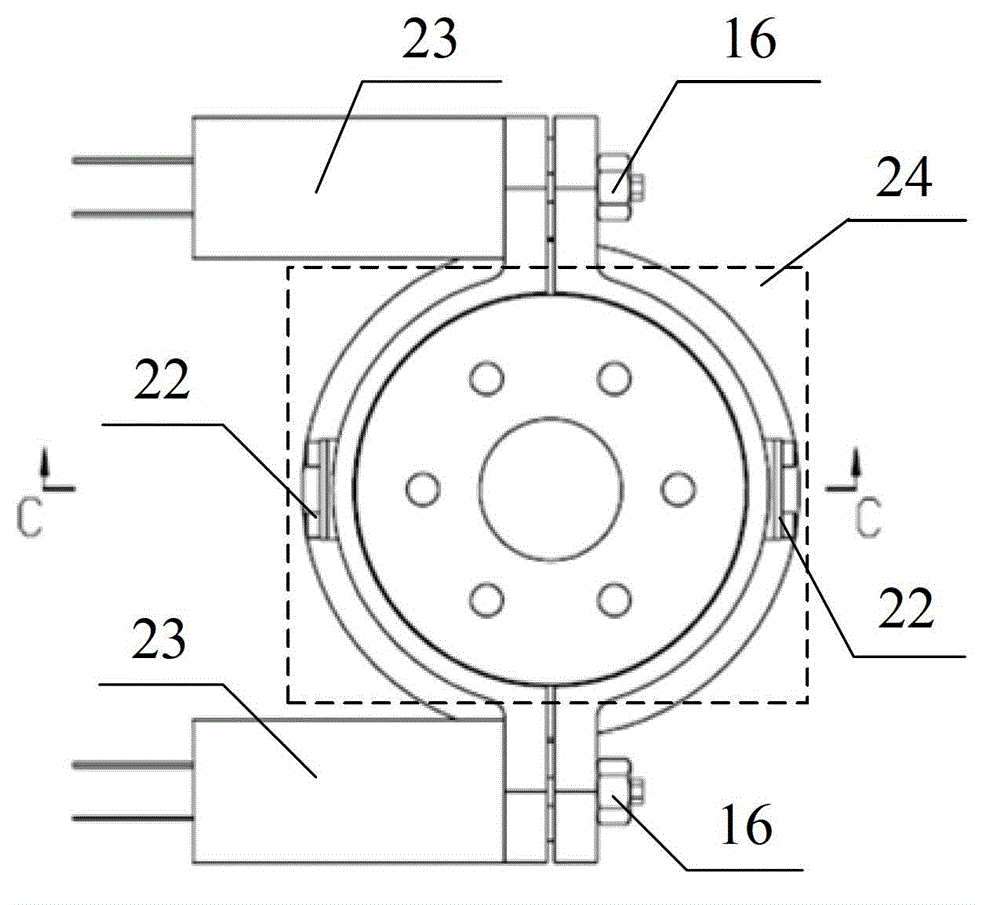

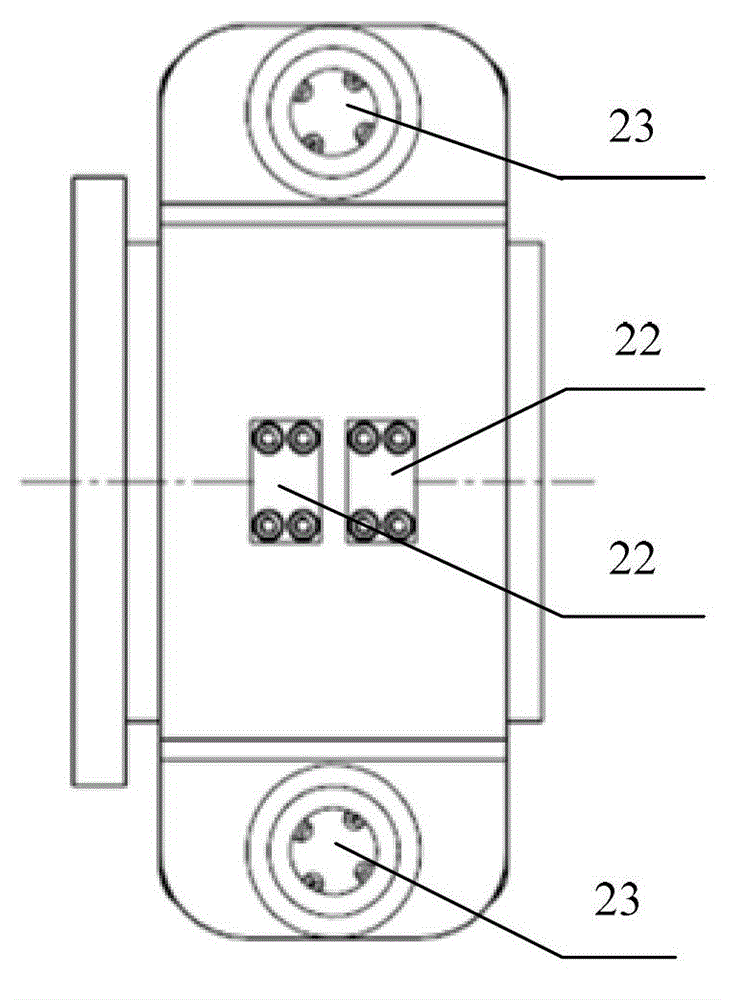

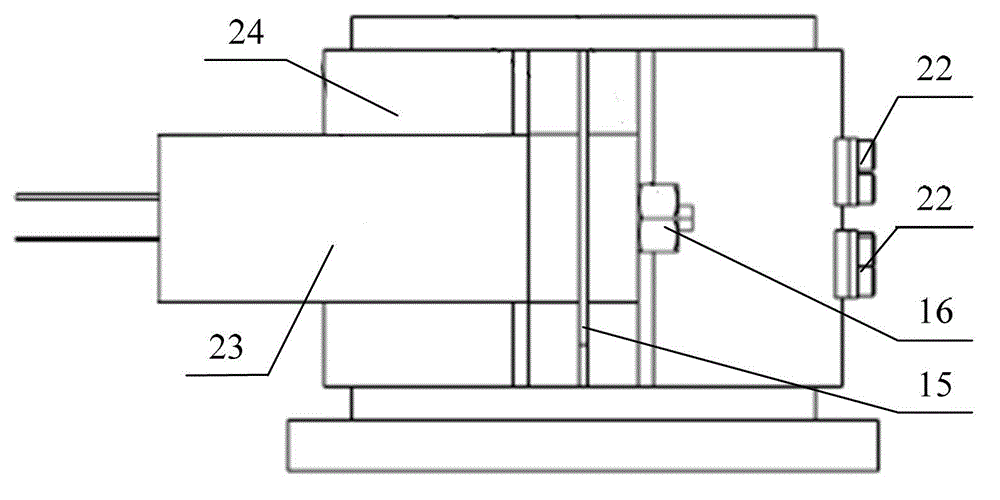

[0023] See attached figure 1 , attached figure 2 and attached image 3 As shown, the unlocking and separating mechanism of the present invention includes a non-impact connection unlocking assembly 23 and a strap-type separation assembly 24; the connecting bolts 1 of the two non-impact connection unlocking assemblies 23 are connected to the described Tape separation assembly 24 is connected.

[0024] See attached Figure 5 The non-impact connection unlocking assembly 23 includes a connecting bolt 1, a lower baffle plate 2, a mounting seat 3, a separation nut A4, a separation nut B5, a guide cylinder 6, a disconnection shaft 9, a memory alloy cylinder 11, a heating plate 12, a spacer Heat cylinder 10, upper baffle plate 14; said mounting seat 3 is divided into left cavity and right cavity, and a through hole is opened in the middle of said left cavity and said right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com