Construction machinery

A technology for construction machinery and sticks, which is applied in the direction of mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., and can solve the problem of complicated supply oil circuits, failure to fully seek effective use of pressure oil, Unable to regenerate the total amount of pressure oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

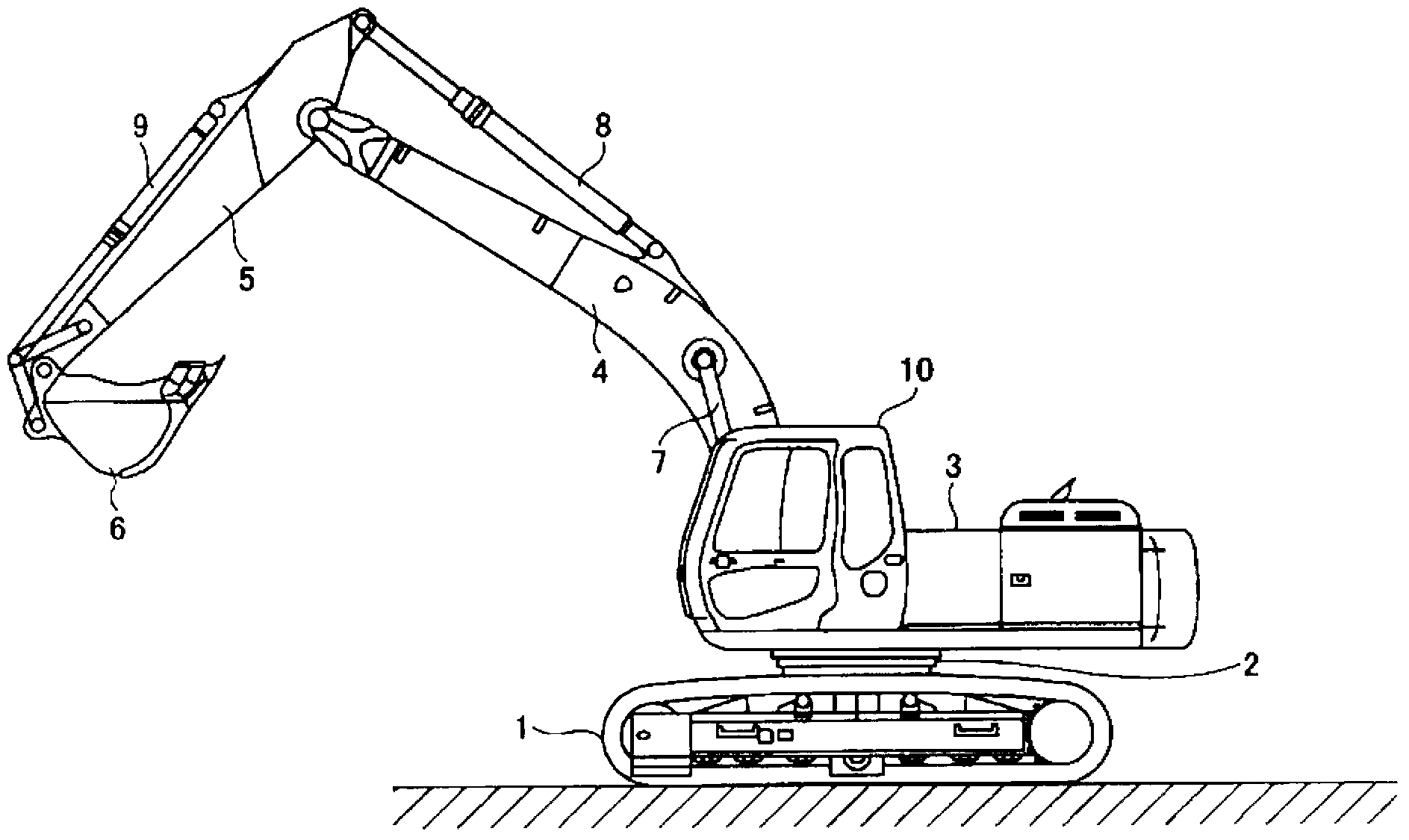

[0024] figure 1 It is a side view showing the hydraulic shovel according to the first embodiment of the present invention. In the hydraulic shovel, an upper revolving body 3 is mounted on a crawler-type undercarriage 1 through a revolving mechanism 2 so as to be rotatable.

[0025] The upper slewing body 3 is equipped with an excavation attachment including a boom 4 , an arm 5 , and a bucket 6 , and a boom cylinder 7 , an arm cylinder 8 , and a bucket cylinder 9 for driving them, respectively, at the front central portion. In addition, the upper revolving structure 3 is equipped with a cab 10 in which an operator rides in the front part, and is equipped with an engine (not shown) as a driving source in the rear part. Hereinafter, the boom cylinder 7 , the arm cylinder 8 , the bucket cylinder 9 , the traveling hydraulic motor (not shown), the swing hydraulic motor (not shown), and the like are collectively referred to as “hydraulic actuators”.

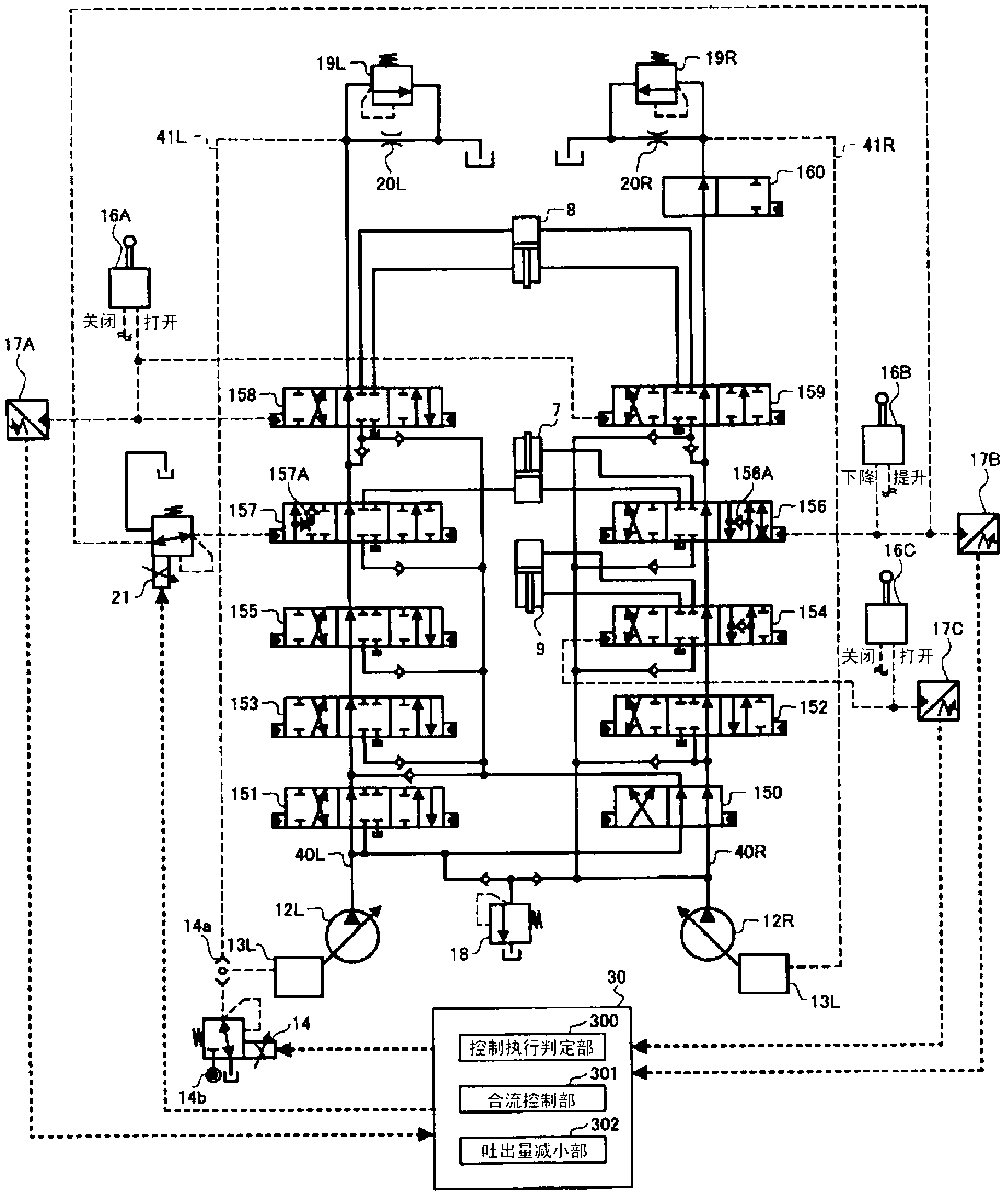

[0026] figure 2 It is a sche...

Embodiment 2

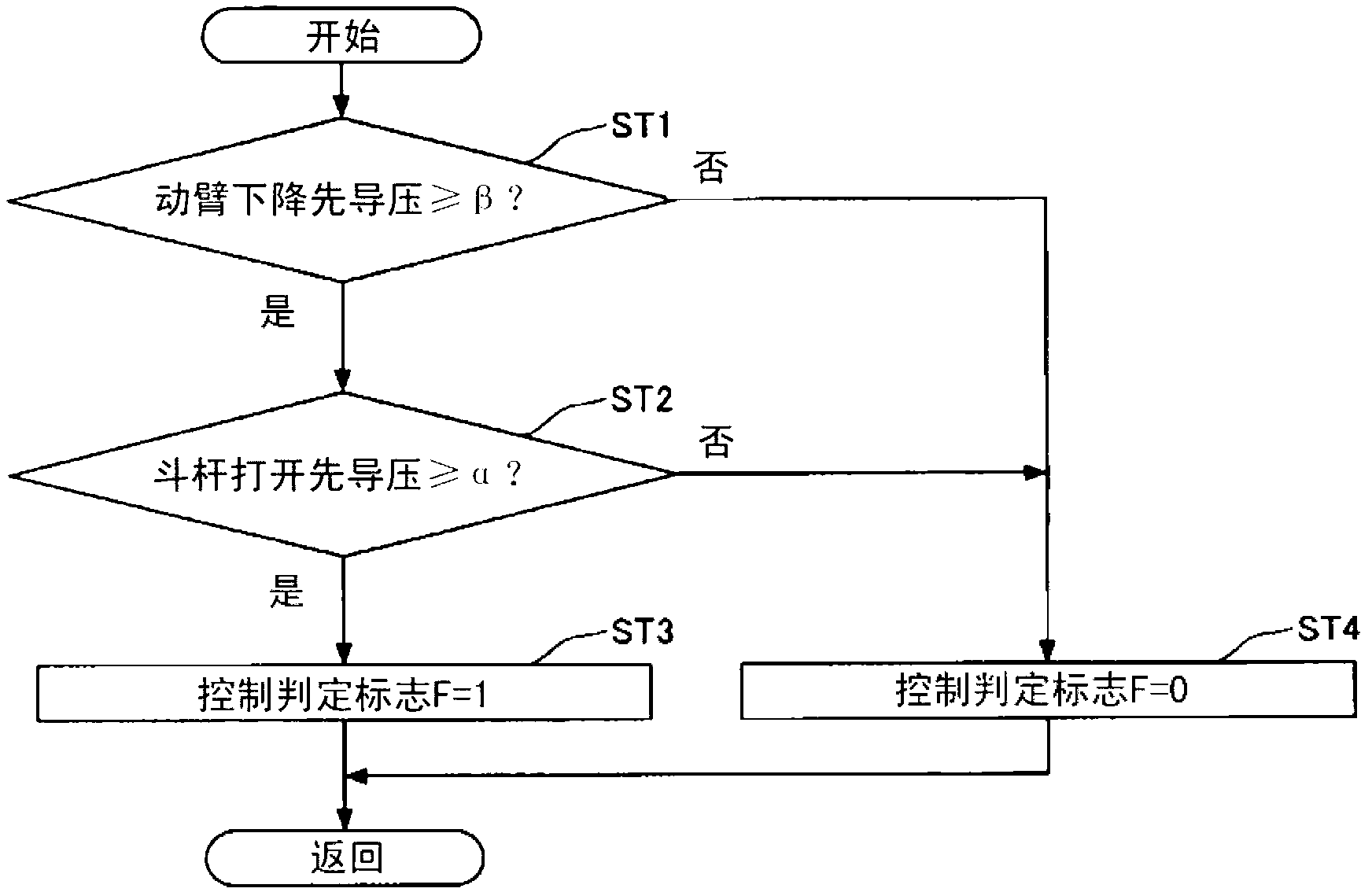

[0110] Next, refer to Figure 5 The control execution determination process executed in the hydraulic shovel according to the second embodiment of the present invention will be described. in addition, Figure 5 It is a flowchart showing the flow of control execution determination processing executed in the hydraulic shovel according to the second embodiment, and the control execution determination processing is continuously executed while the hydraulic shovel is in operation.

[0111] in addition, Figure 5 The control execution judgment processing of the control execution is different from the control start condition and the control release condition in that image 3 The control execution judgment processing is different.

[0112] Therefore, the description of the common points will be omitted, and the differences will be described in detail. In addition, the same reference signs as those used to describe the hydraulic shovel according to the first embodiment are used.

...

Embodiment 3

[0126] Next, refer to Image 6 and Figure 7 A hydraulic shovel according to a third embodiment of the present invention will be described. in addition, Image 6 It is a schematic diagram showing a configuration example of a hydraulic circuit mounted on a hydraulic shovel according to the third embodiment. Image 6 and figure 2 In the same way, the high pressure oil circuit, pilot oil circuit and electric drive / control system are represented by solid line, dotted line and dotted line respectively. in addition, Figure 7 It is a flowchart showing the flow of control execution determination processing executed in the hydraulic shovel according to the third embodiment, and the control execution determination processing is continuously executed while the hydraulic shovel is in operation.

[0127] Image 6 In the point of having the arm rod pressure sensor 17D and the arm cylinder bottom pressure sensor 17E, it is the same as the figure 2 The hydraulic circuits involved in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com