Composite fiber cement board structure

A fiber cement board and composite technology, applied in the direction of building materials, etc., can solve the problems of weak stress resistance, easy breakage, and failure to solve the stress resistance of fiber cement boards, and achieve the effect of overcoming weak stress resistance and widening market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

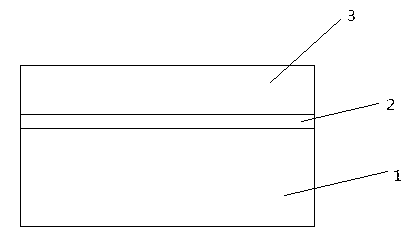

[0017] figure 1 It is a structural schematic diagram of a preferred implementation of the present invention. refer to figure 1 As shown, a composite fiber cement board structure of the present invention includes: a fiber cement board layer 1, a wood board layer 2 and is arranged between the fiber cement board layer 1 and the wood board layer 2, and is used for combining fiber cement Adhesive layer 3 for ply 1 and wood ply 2 .

[0018] The present invention does not intend to limit the material of the fiber cement slab 1 , but as a preference of the present invention, the material of the fiber cement slab 1 includes cement, inorganic fiber, organic fiber and mica.

[0019] As a further preference, cement accounts for 50-70% of the overall weight of the fiber cement slab 1, inorganic fibers account for 10-20% of the overall weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com