Structure of buffering type swing valve oil cylinder of concrete pump

A pendulum valve oil cylinder and concrete pump technology, which is applied to parts of pumping devices for elastic fluids, pump elements, variable capacity pump parts, etc., and can solve problems such as reduced equipment system life, loud equipment noise, and damaged equipment , to achieve the effect of overcoming the impact phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

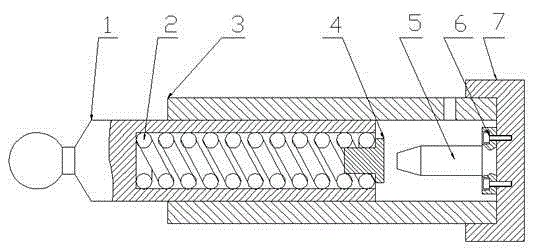

[0009] A structure of a concrete pump buffer pendulum valve cylinder, including a plunger 1, a compression spring 2, a cylinder body 3, an impact block 4, an impact rod 5, a bolt 6, and a cylinder head 7, and a plunger 1 is arranged in the cylinder body 3 A cylinder head 7 is arranged at the bottom of the cylinder body 3, a blind hole is formed in the middle of the plunger 1, a compression spring 2 is arranged in the blind hole in the middle of the plunger 1, and an impact block is fixedly installed on the outer end of the compression spring 2 4. Install and fix a striking rod 5 at the middle part of the cylinder head 4 through a bolt 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com