Connecting device for motor connecting

A technology for connecting devices and mounting holes, which is applied in the direction of mechanical equipment, rigid shaft couplings, couplings, etc., can solve problems such as difficult to realize, affect motor performance, and leave a large space, so as to reduce machining accuracy requirements, The assembly operation is simple and convenient, and the operation space requirement is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The connection device for motor connection of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

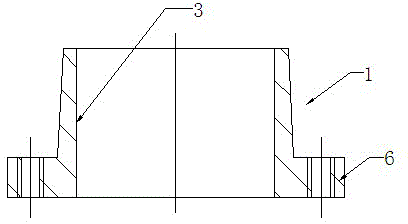

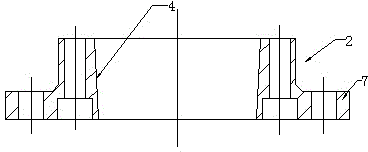

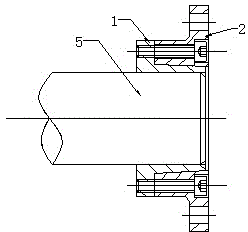

[0013] Such as figure 1 , figure 2 As shown, the connecting device for motor connection of the present invention includes an inner ring 1 and an outer ring 2, the inner ring 1 is two semi-conical truncated cones with a base, and the center of the inner ring is provided with an inner hole that matches the shaft 3. The outer ring 2 is a cylinder with a base, and the center of the outer ring 2 is provided with an inner tapered surface 4 matching the outer diameter of the inner ring, such as image 3 As shown, after the inner ring 1 is set on the shaft 5, the inner tapered surface 4 of the outer ring 2 is matched with the outer diameter of the inner ring and the inner ring 1 is pressed and fixed on the shaft 2, wherein the inner ring base 6 and the outer ring base 7 is provided with mounting holes at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com