Wall-through sealing structure of supercharged boiler

A technology of sealed structure and pressurized boilers, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc. It can solve the problems of high furnace temperature, increased boiler double-layer shell expansion, and increased boiler structure difficulty. Achieve the effect of safe and stable operation and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

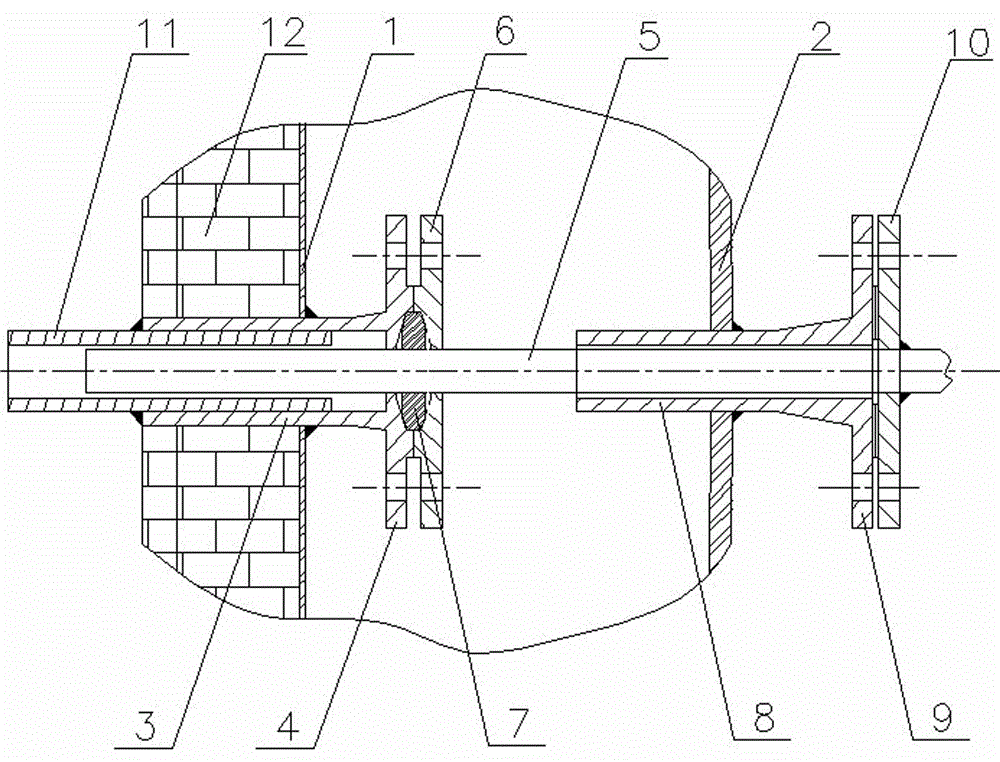

[0012] Examples of the present invention figure 1 As shown, the boiler with the wall-penetrating sealing structure of the supercharged boiler is a double-layer structure, and the brick lining 12 is provided with an inner shell guard plate 1 and an outer shell 2, and the inner shell guard plate 1 is sealed and welded with an inner sleeve that penetrates into the boiler The outer end of the tube 3 and the inner sleeve 3 is connected with an inner flange 4, and the inner sleeve 3 is provided with an insertion tube 5 that penetrates to the inside of the boiler and the other end to the outside of the shell 2, and the insertion tube 5 and the inner flange 4 1. The inner flange mating discs 6 are sealed and connected through the packing 7; the casing 2 is sealed and welded with an outer casing 8 that penetrates into the casing 2 and is set on the insertion tube 5, and the outer end of the outer casing 8 is connected with an outer flange 9. The outer sleeve 8 is welded to the outer fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com