Array substrate, and 3D display device and drive method thereof

A technology of an array substrate and a driving method, which is applied in the field of 3D display, can solve problems such as rising product cost, lowering display device transmittance, and low yield rate of display device products, so as to reduce charging time, ensure charging time, and improve refresh rate. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

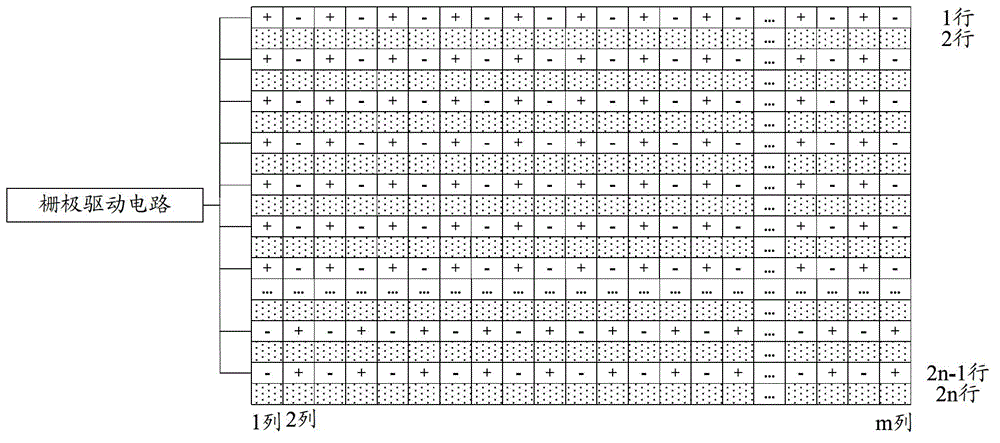

Embodiment 1

[0028] When the refresh frequency of the display device is 60Hz, assuming that there are 1126 rows of pixel units on the array substrate, the turn-on time of each row of pixel units is 1 / (1126*60)s, which is about 14.8us, in order to To realize 3D display, it is necessary to increase the refresh frequency of the display device to 120Hz, so that the charging time of the pixel electrodes will be reduced. In order to ensure the charging rate of the pixel electrodes, in the prior art, it is often necessary to increase the line width of the wires on the array substrate to reduce The load on the display device will reduce the transmittance of the display device; and the response time of the display device with a high refresh rate is insufficient, resulting in poor picture quality.

[0029] In order to avoid the above-mentioned problems, this embodiment provides an array substrate, including a substrate, and 2n rows of pixel units formed on the substrate in matrix form, and the array ...

Embodiment 2

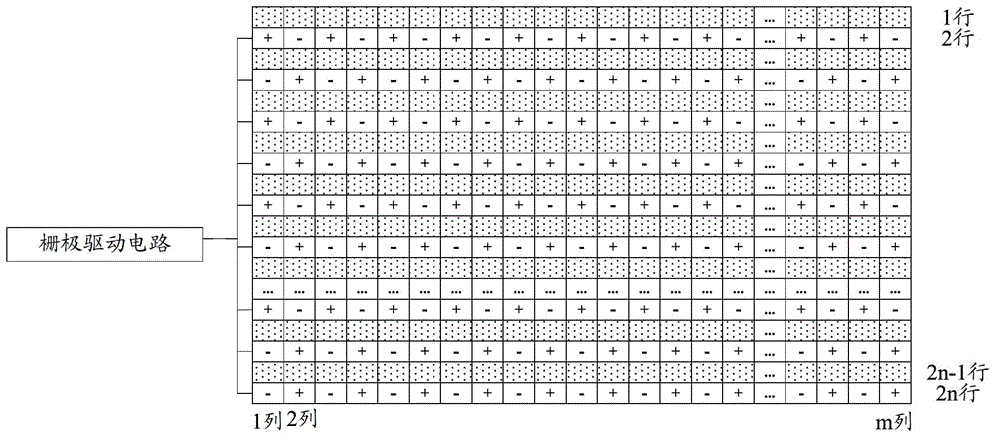

[0043] When the refresh frequency of the display device is 60Hz, assuming that there are 1126 rows of pixel units on the array substrate, the turn-on time of each row of pixel units is 1 / (1126*60)s, which is about 14.8us, in order to To realize 3D display, it is necessary to increase the refresh frequency of the display device to 120Hz, so that the charging time of the pixel electrodes will be reduced. In order to ensure the charging rate of the pixel electrodes, in the prior art, it is often necessary to increase the line width of the wires on the array substrate to reduce The load on the display device will reduce the transmittance of the display device; and the response time of the display device with a high refresh rate is insufficient, resulting in poor picture quality.

[0044] In order to avoid the above-mentioned problems, this embodiment provides an array substrate, including a substrate, and 2n rows of pixel units formed on the substrate in matrix form, and the array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com