Barrel type upper and lower yoke structure three-phase isolation transformer

A technology of isolating transformers and yoke structures, applied in the field of transformers, which can solve problems such as complex structures, difficulty in adjusting transformer no-load current, troublesome assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

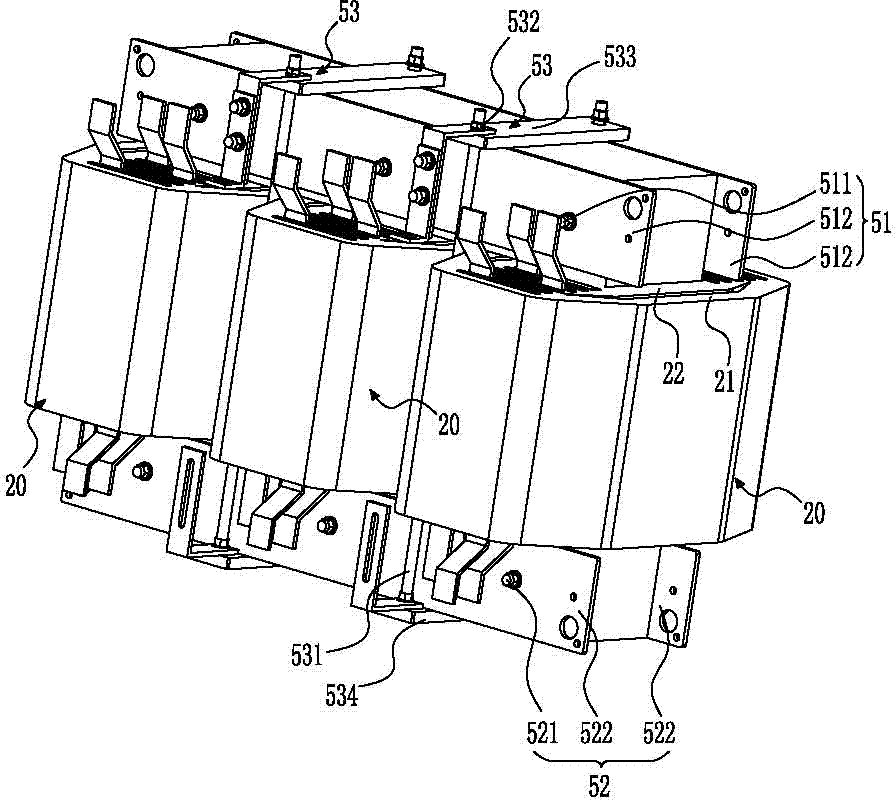

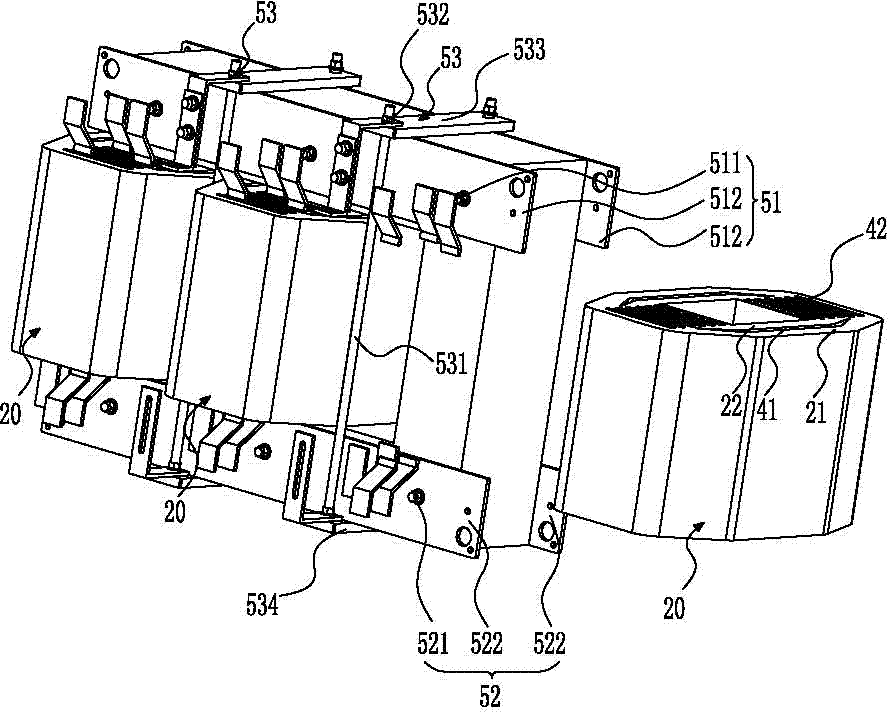

[0034] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including an iron core 10, a winding 20, and a fixing structure for fixing the winding 20 and the iron core 10. Each winding 20 includes a primary winding 21 and Secondary winding 22.

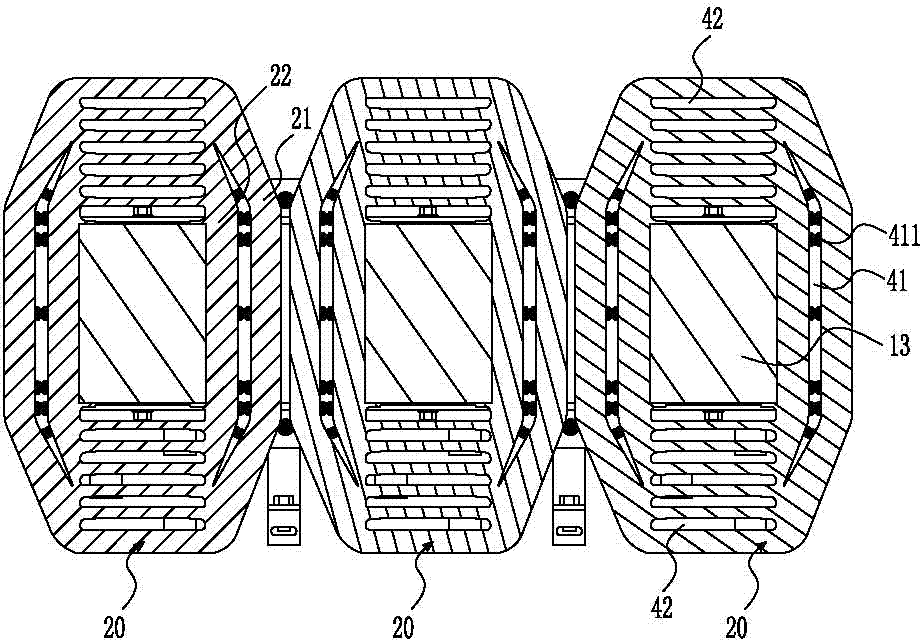

[0035] Such as Figure 4 to 6 As shown, the iron core 10 includes an upper yoke 11, a lower yoke 12, and three center pillars 13. The three center pillars 13 are arranged side by side in parallel, and the top and bottom edges are correspondingly flush. The yokes 12 are respectively located at the upper and lower positions of the center column 13, and an air gap 30 is formed between the upper yoke 11, the lower yoke 12 and the top and bottom ends of the center column 13, by adjusting the upper and lower yokes 11, 12 and The size of the air gap 30 between the center pillars 13 can be adjusted so that the no-load current can be adjusted.

[0036] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com