Three phase earthing switch structure driven by duplex pull rods and distributed in I shape

A technology of grounding switch and double pull rod, which is applied in the direction of electric switch, high-voltage air circuit breaker, electrical components, etc. It can solve the problems of sudden drop of clamping force of the contact finger, burning of the grounding switch, and sudden increase of contact resistance, so as to reduce the closing Effects of resistance, reliable operation, reduced torsional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

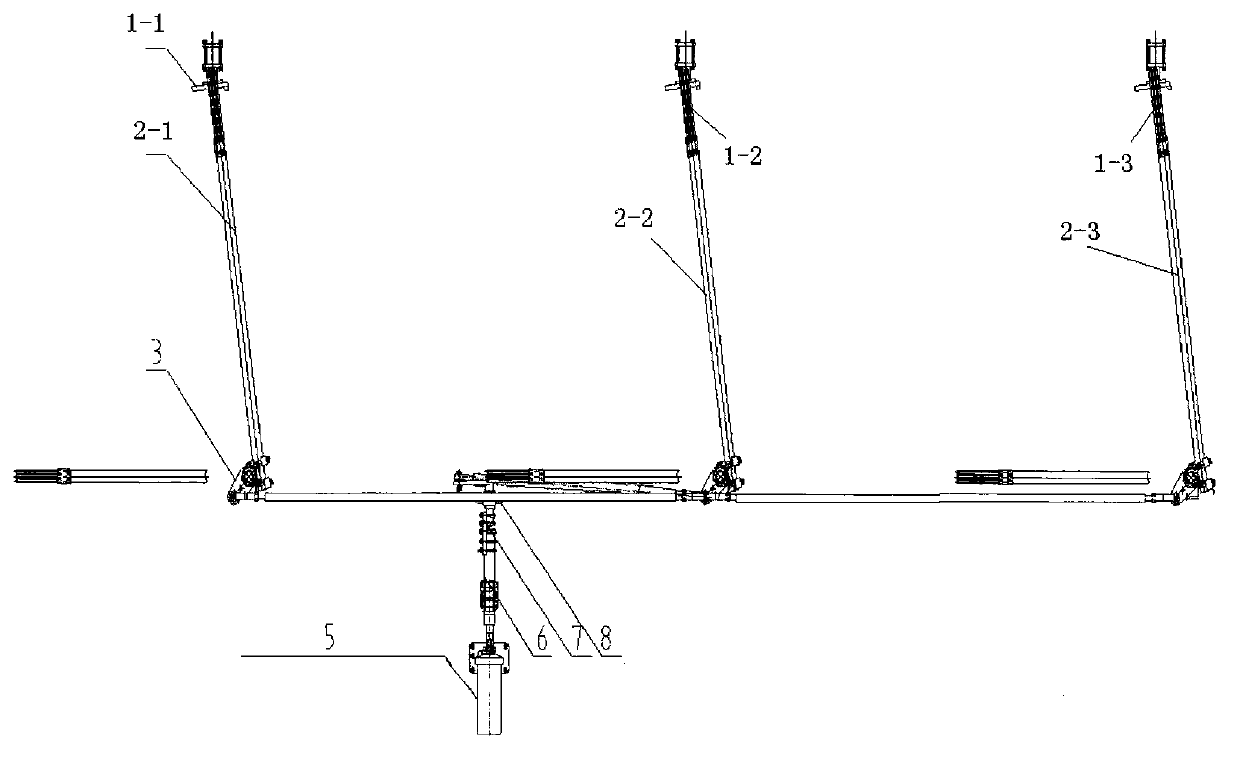

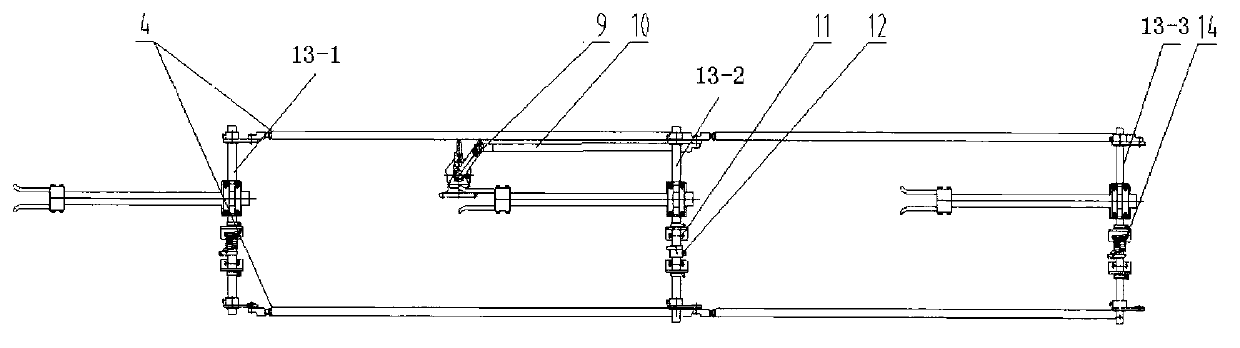

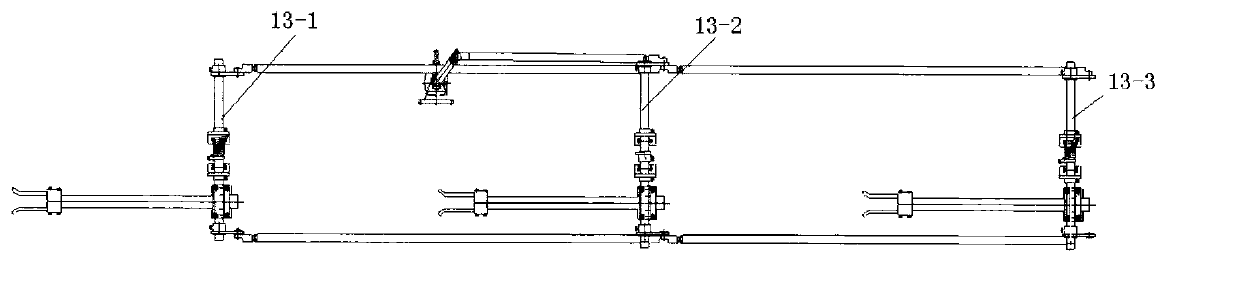

[0019] Such as figure 1 and figure 2 As shown, the present invention provides a three-phase inline arrangement grounding switch structure driven by double tie rods, including A phase moving contact assembly 2-1, B phase moving contact assembly 2-2 and C Phase A moving contact assembly 2-3, one end of A phase moving contact assembly 2-1, B phase moving contact assembly 2-2 and C phase moving contact assembly 2-3 are respectively connected to A phase static contact assembly 1- 1. Phase B static contact assembly 1-2 and C phase static contact assembly 1-3, the other ends of which are respectively tightly hugged with A phase rotating shaft 13-1, B phase rotating shaft 13-2 and C phase rotating shaft 13-3, A-phase rotating shaft 13-1, B-phase rotating shaft 13-2 and C-phase rotating shaft 13-3 respectively pass through A-phase bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com