Method and device for automatic detection of high-voltage resistance of spark plug

An automatic detection device and automatic detection technology, applied in the direction of spark plugs, circuits, electrical components, etc., to achieve the effect of simplifying the debugging part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

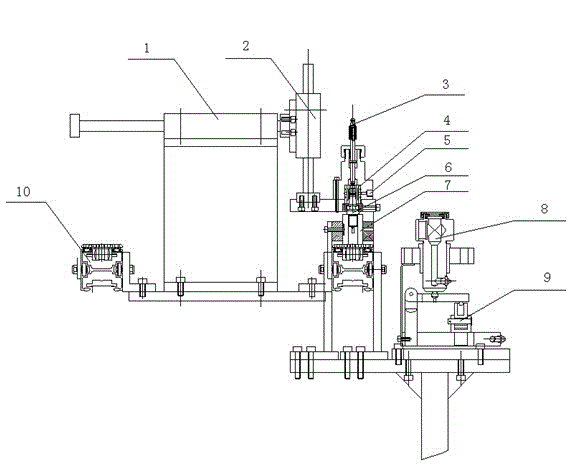

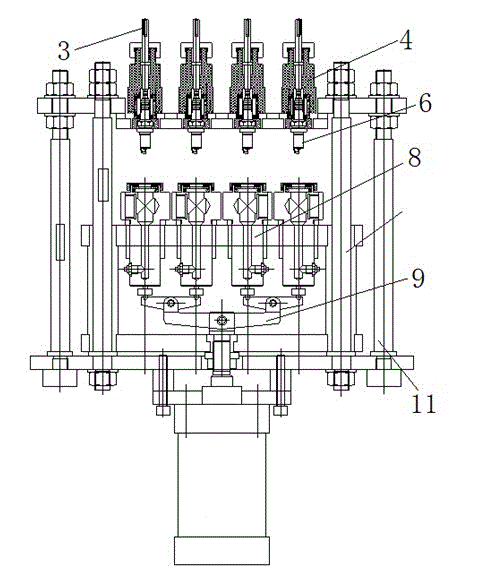

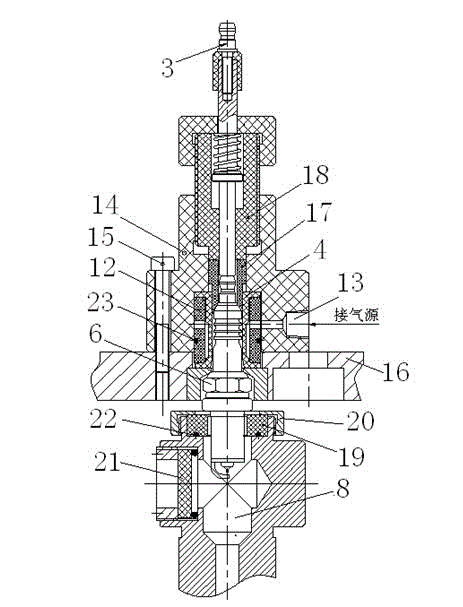

[0041] attached Figure 1-2 An embodiment of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to a method for automatic detection of high-voltage withstand voltage of spark plugs applied to production lines. The spark plug 6 is clamped, so that the ignition thread end is inserted downward into a gas-sealed chamber, and 1.6Mpa high-pressure air is filled into the sealed chamber; Based on the principle of voltage drop after high voltage breakdown, the voltage signal is sent to the Programmable Logic Controller (PLC) for sampling conditioning and window judgment through the special circuit detection board, and the qualified pulse train is transmitted to the controller to judge the detected pulse according to the parameter setting. Whether the withstand voltage of the spark plug is qualified.

[0042] Further, the spark plug to be inspected is clamped by a clamping mechanism on the assembly line, and the spark pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com