Novel through-flow type cereal cleaning device

A cleaning device, a through-flow technology, applied in the field of a new type of through-flow grain cleaning device, can solve the problems of uneven axial wind speed, air turbulence, large cleaning loss and impurity content, etc., to achieve improved cleaning Effect, low manufacturing cost, good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with description accompanying drawing, the present invention will be further described, but the present invention is not limited to following embodiment

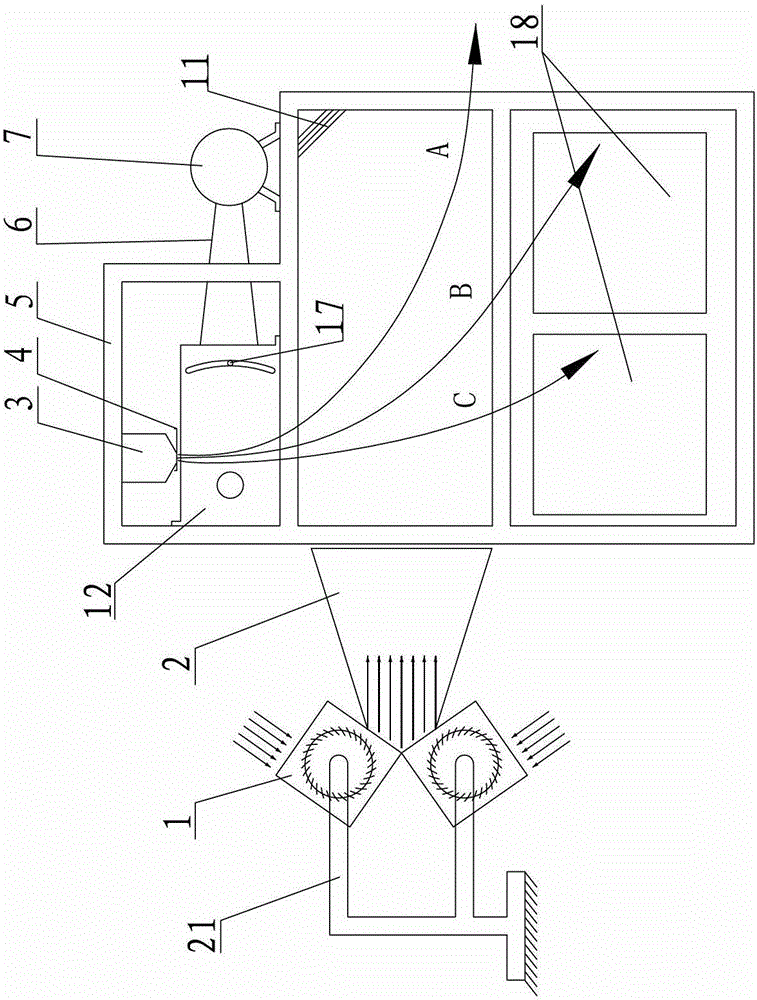

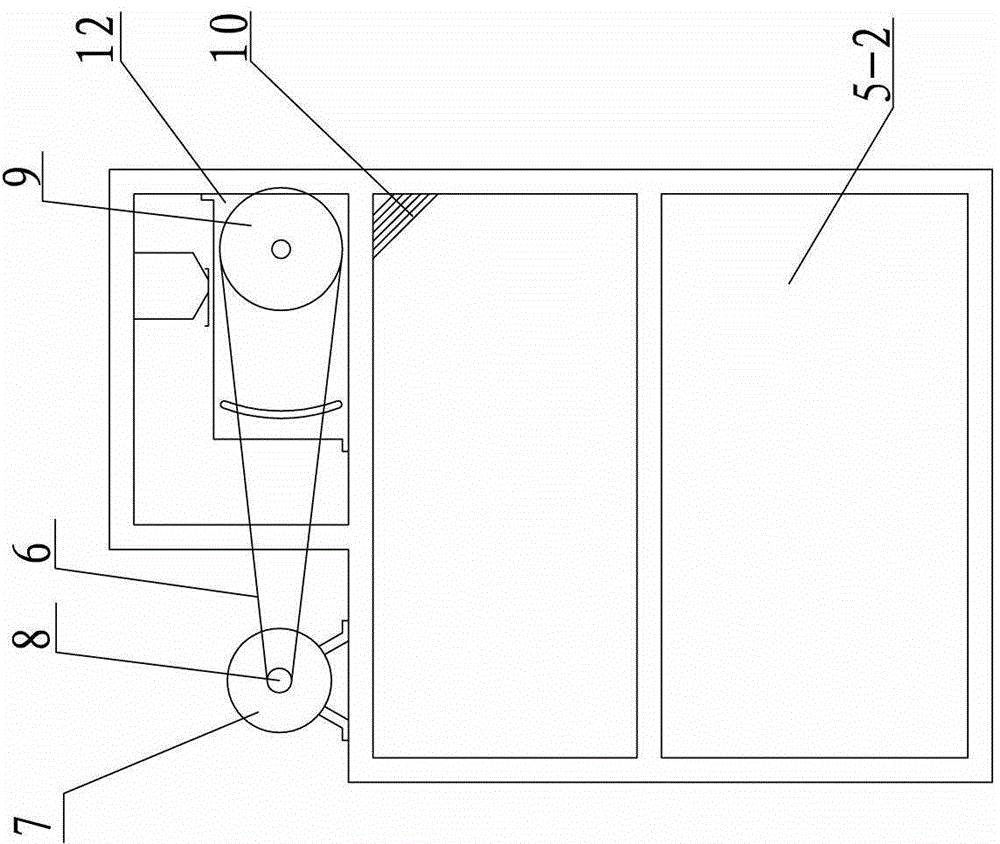

[0033] Such as figure 1 , figure 2 As shown, a novel through-flow grain cleaning device of the present invention includes a frame 5, a feeding mechanism installed on the top of the frame, and an air source device installed on the side of the frame.

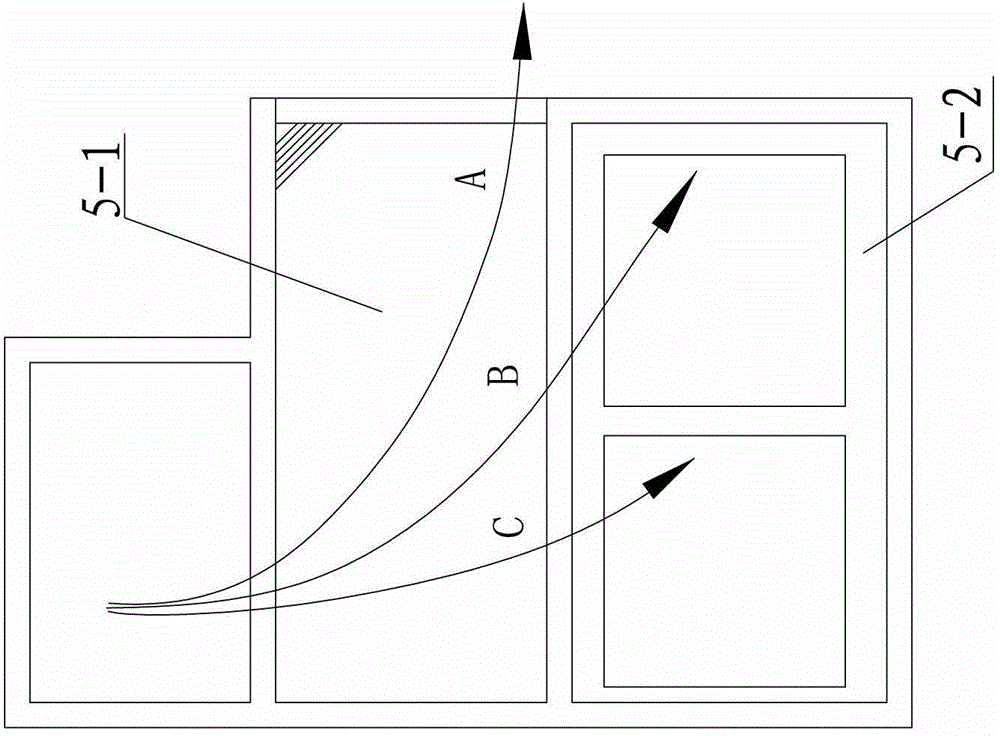

[0034] Such as Figure 3 ~ Figure 5 As shown, the frame is made of aluminum profiles, the frame is provided with a cleaning chamber 5-1 and a receiving chamber 5-2 below it, and the front and rear sides of the cleaning chamber are provided with baffles (the front side is transparent Baffle plate 11, the rear side is white baffle plate 10, is convenient to observe the working situation in the cleaning room), the left side is the air inlet 5-3 that is connected with the wind source device, the right side opens to form the impurity outlet, the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com