Smoke wet oxidation denitration method

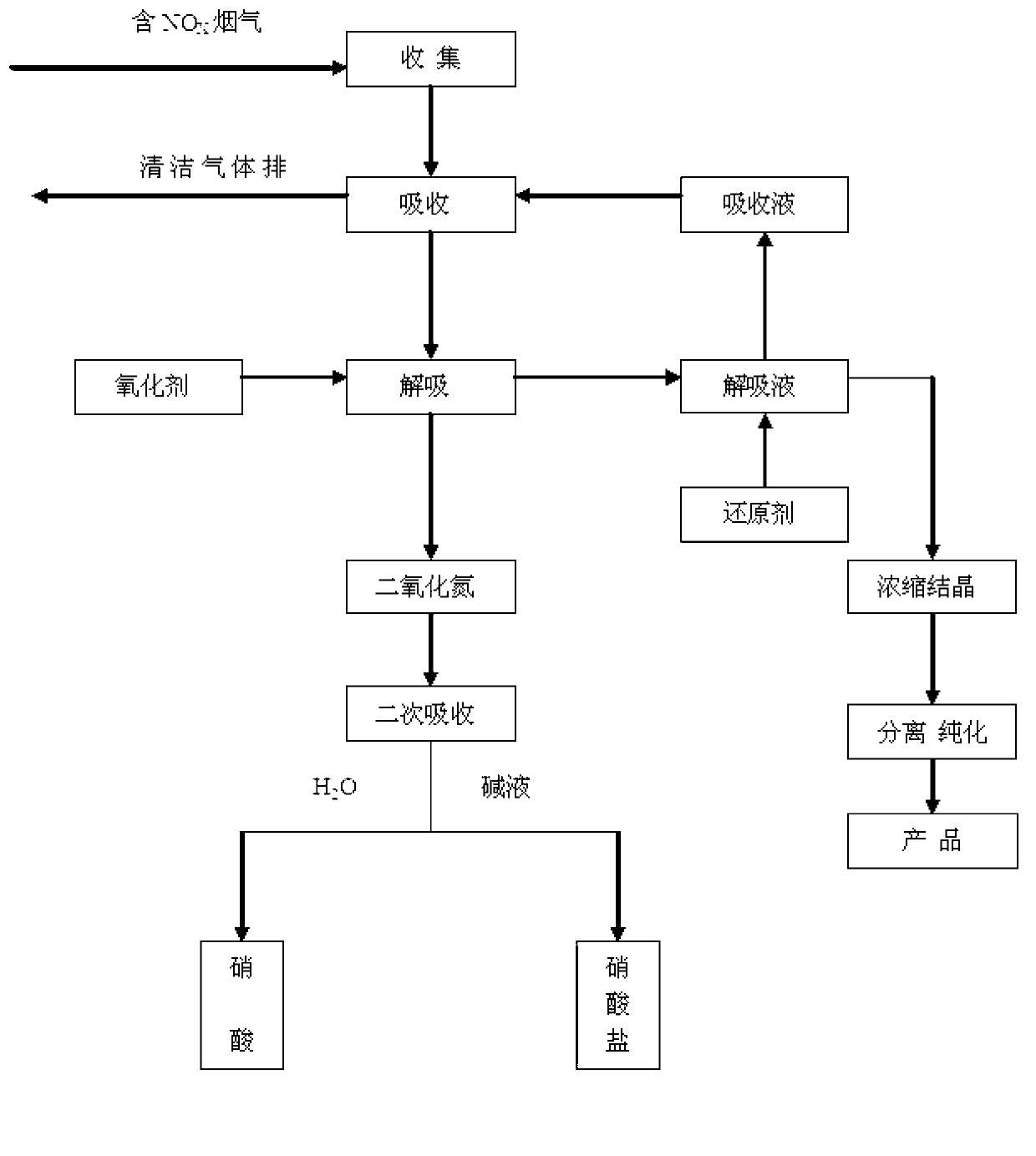

A technology of wet oxidation and nitric oxide, which is applied in the field of flue gas wet oxidation and denitrification, can solve the problems of high operating costs, insufficient catalyst strength, and easy poisoning, and achieve huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 1L of ferric chloride solution with hydrogen ion concentration of 1mol / L and ferrous iron concentration of 2.7mol / L, then feed nitrogen monoxide gas at 30°C under one atmospheric pressure, the amount of feed is 1.7mol, and the reaction The time is 0-4h, until the absorption liquid turns dark brown and stops. After standing for 1 hour, the absorption liquid is fed with 1.35mol of oxygen, and the reaction time is 3-5h. The released nitrogen dioxide gas is absorbed by 1L distilled water until it is released. until there is no nitrogen dioxide in the residual gas. The concentration of nitric acid contained in the absorption liquid was measured to be 0.77 mol / L.

Embodiment 2

[0026] Take a part of the flue gas discharged from a pit mouth power plant, pass it into a ferrous iron solution with a hydrogen ion concentration of 1mol / L and a concentration of 1.8mol / L, and absorb NO at 70°C X Generate dark brown mixed solution of nitrosoferrous salt, nitric acid and nitrous acid. After one year, take 5L of the mixed solution gained from denitrification treatment, feed excess oxygen, and the blown nitrogen dioxide is absorbed by water to obtain a concentration of 200ml of 0.1mol / L dilute nitric acid solution. This shows that the temperature is high and the time is long, the absorption effect and resource utilization effect will be reduced.

Embodiment 3

[0028] Get hydrogen ion concentration and be 0.7mol / L, divalent iron concentration is 300ml of ferric chloride solution of 1.3mol / L, then at 30 ℃, under one atmospheric pressure, pass into nitric oxide gas, and pass into amount is 0.39mol, The reaction time is 0-3h, until the absorption liquid turns dark brown and stops. After standing for 1 hour, the absorption liquid is fed with 0.22mol of oxygen, and the reaction time is 0-5h. The released nitrogen dioxide gas is absorbed by 500ml of distilled water until Released residual gas until there is no nitrogen dioxide. The concentration of nitric acid contained in the absorption liquid was measured to be 0.48 mol / L.

[0029] A flue gas wet oxidation denitrification method provided by the present invention has the following beneficial effects:

[0030] 1. Change the existing treatment process to achieve denitrification while reducing investment costs, device scale, and operating costs. This is a major breakthrough in flue gas deni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com