Method for separating fine powder from limestone

A separation method and limestone technology, applied in the direction of the swirling axial reversible device, swirling device, etc., can solve the problem that the ultrafine powder of limestone cannot be effectively separated, and achieve the improvement of dust removal effect, easy operation, and service cycle. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

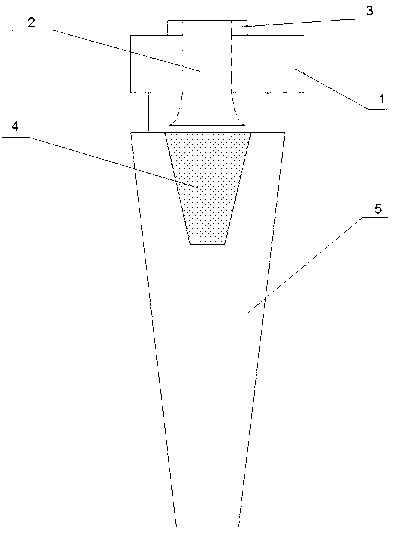

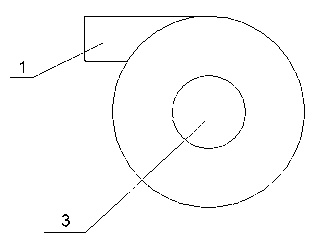

[0029] refer to Figure 1~Figure 3 , the limestone crushing equipment adopts the ZYF600 type punching powder mill 12, the limestone raw material 11 is sent to the powder mill 12, and the limestone particles are crushed into 5-400 mesh particles, and the crushed materials are sent tangentially from the entrance 1 through the centrifugal fan. In the cyclone separator 13.

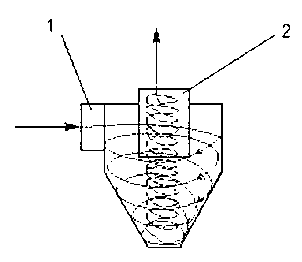

[0030] The material moves spirally along the inner wall in the cyclone separator, and the particles with a fineness less than 325 mesh fall into the bottom of the conical cylinder 5 under the action of gravity, and are discharged through the ash discharge port (lower outlet).

[0031] The remaining materials in the cyclone separator 13 pass through the filter device 4 along with the air flow, and are sent to the air outlet 3 (upper outlet) of the cyclone separator by the central exhaust pipe 2. The large bottom surface of the filter device 4 is located on the upper edge of the cone, and the small bottom surfac...

Embodiment 2

[0035] Referring to Example 1, the limestone crushing equipment adopts the ZYF600 rotary pulverizer 12 to crush the limestone particles into 5-400 mesh particles, and the crushed materials are sent tangentially from the inlet 1 to the cyclone separator 13 by a centrifugal fan.

[0036] The materials do spiral movement in the cyclone separator, and the particles with a fineness of less than 325 mesh fall into the bottom of the conical cylinder 5 under the action of gravity, and are discharged through the ash discharge port; the remaining materials are filtered by the hollow filter device 4 with the air flow, and then exhausted from the center The pipe 2 is sent to the air outlet 3 of the cyclone separator. The large bottom surface of the filter device 4 is at the top and the small bottom surface is at the bottom. The filter device 4 has a diameter of 600mm at the bottom, a diameter of 350mm at the bottom, a height of 1.6m, and a filter aperture of 45μm, which can further prevent...

Embodiment 3

[0040] Referring to Example 1, the limestone crushing equipment adopts the ZYF600 rotary pulverizer 12 to crush the limestone particles into 5-400 mesh particles, and the crushed materials are sent tangentially from the inlet 1 to the cyclone separator 13 through a centrifugal fan.

[0041] The material does spiral movement in the cyclone separator 13, and the particles with a fineness of less than 325 mesh fall into the bottom of the conical cylinder 5 under the action of gravity, and are discharged through the ash discharge port. Powder particles (the size of the mesh can be adjusted according to needs to determine the particle size of cooking) are stored in the transition chamber 18, and then the medium powder particles 30 are released, packaged and transported to be used as hearth desulfurized limestone particles; the remaining coarse particles are sent back to the pulverizer 12 To crush.

[0042] The remaining materials in the cyclone separator 13 are filtered by the holl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap