Double-cone uncoiler, buffer cone head of coiler and cone head buffering method

A technology of uncoiler and coiler, which is applied to the main components of aluminum foil rolling mills and the field of plate and strip finishing equipment. It can solve the problems of severe mechanical wear and difficult unloading of reels, and reduce mechanical wear and mechanical collision wear. , the use of good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

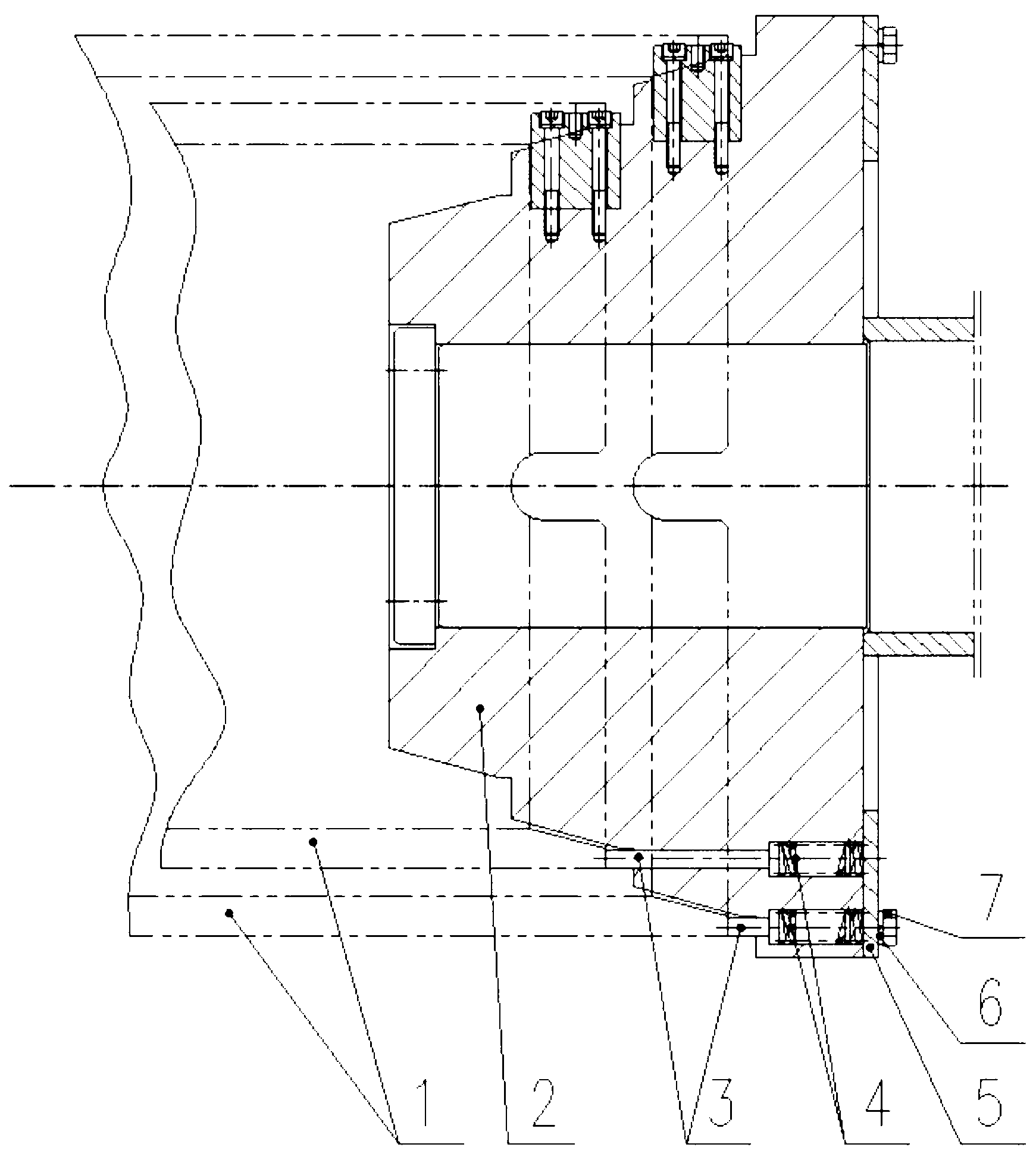

[0021] combine figure 1 , a double-cone uncoiler, a buffer cone of a coiler, including: a cone 2 corresponding to the sleeve 1, a buffer mechanism; each stepped end surface of the cone 2 is provided with a number of cones toward the axis of the cone There are three circle stepped round holes; each circle stepped round hole is provided with a buffer mechanism.

[0022] The buffer mechanism is composed of a "T"-shaped rod 3, a spring 4, and a pressure plate 5. The "T"-shaped rod is arranged in a stepped circular hole, and the small-diameter end of the "T"-shaped rod and the small diameter of the stepped circular hole on the cone head The hole forms a clearance fit, and the small-diameter end face of the T-shaped rod is in close contact with the end face of the sleeve; the end face of the large-diameter section of the "T"-shaped rod bears on the spring, and the other end of the spring touches the pressure plate 5 on the end face, and the pressure plate 5 is tightened with screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com