Method for achieving process of on-line punching cold-roll-forming cutting production line

A technology of cold-bending forming and realization method, which is applied in the field of online punching and cold-bending forming and cutting production line technology, which can solve the problems of high energy consumption, low production efficiency, and high labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

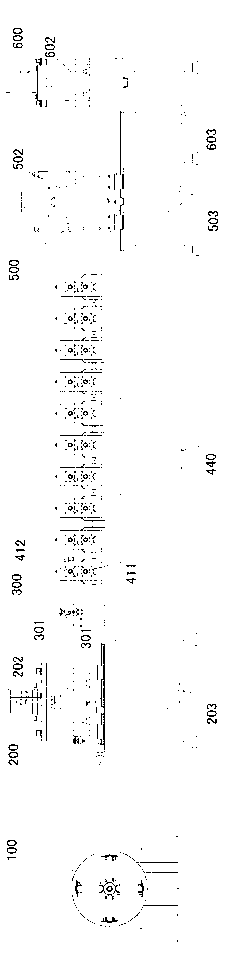

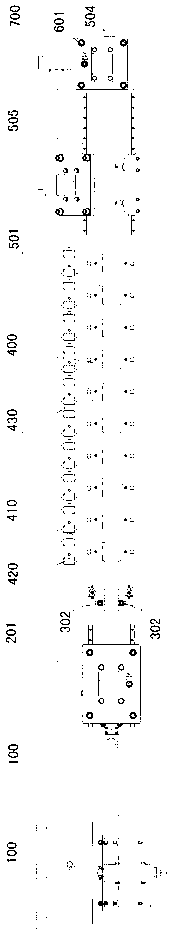

[0022] Such as figure 1 with figure 2 As shown, the implementation method of the online punching cold-formed forming cutting production line technology of the present invention, the specific content is as follows:

[0023] Place the steel strip 900 (coiled steel strip) on the rotary uncoiler 100, and lead one end of the steel strip into the primary punching hydraulic station 200. The punching hydraulic station 200 is driven by the punching cylinder 201 placed on the top. The stamping tool 202 of the punch punches the hole.

[0024] The punched steel strip is introduced into the feed guide device 300. The feed guide device is provided with a pair of vertical conveying axles 301 that are tightly attached to each other to avoid curling of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com