A bulletproof knife overcut mechanism for mold processing

A technology of mold processing and bulletproof knife, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of overcutting, loss, and mold scrapping of the bullet knife, and achieve the reduction of overcut and contact area of the bullet knife , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

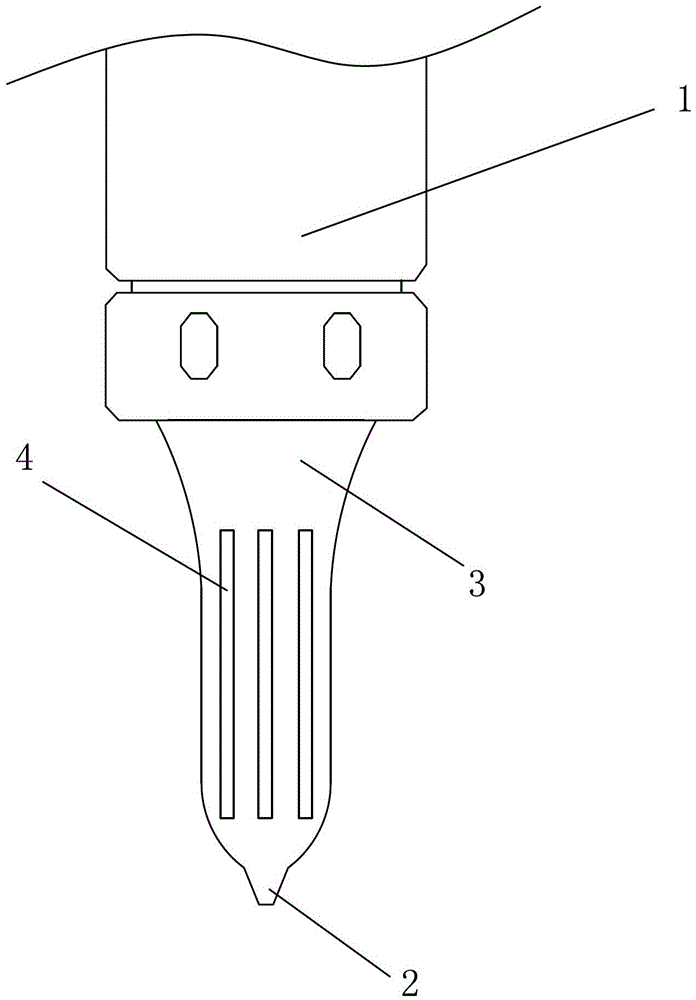

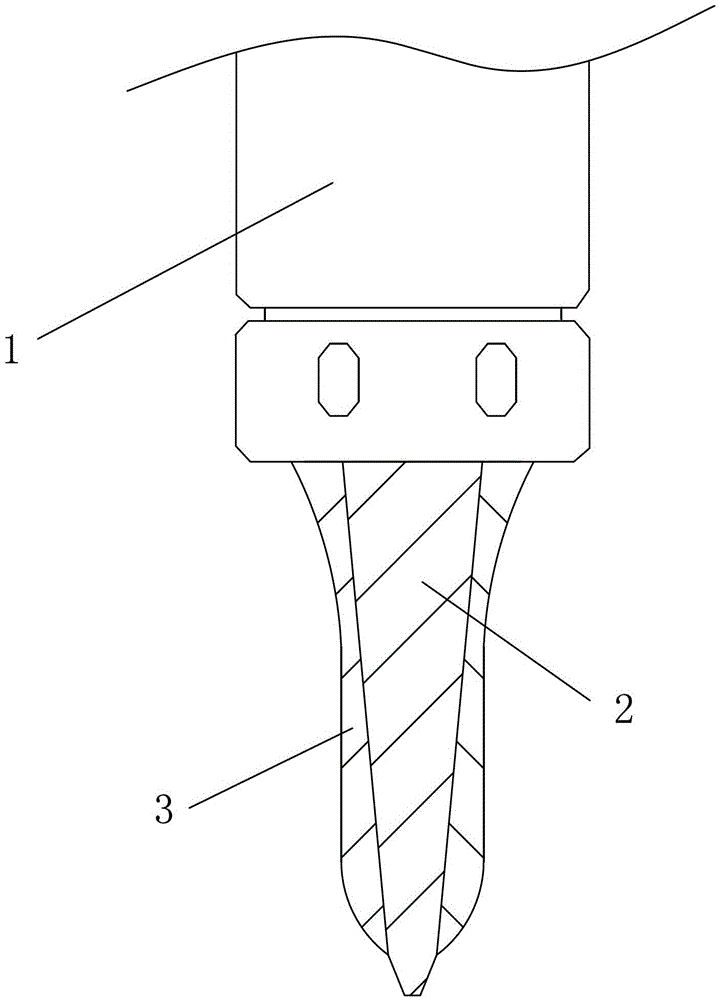

[0016] Such as Figures 1 to 2 A bullet-proof knife overcut mechanism for mold processing shown includes a tool mounting seat 1, a tool 2 is connected in the tool mounting seat 1, and the tool 2 is sleeved to reduce emergency stop reaction. The protective cover 3 is fixedly connected to the tool mounting seat 1 to the deformation amount of the cutter 2 during the processing so as to reduce the overcut of the spring knife.

[0017] In the present invention, a plurality of reinforcing ribs 4 are provided on the outer wall of the protective cover 3 . The reinforcing ribs 4 are arranged along the length direction of the tool.

[0018] The edge of the knife 2 described in the present invention is a thin R angle edge.

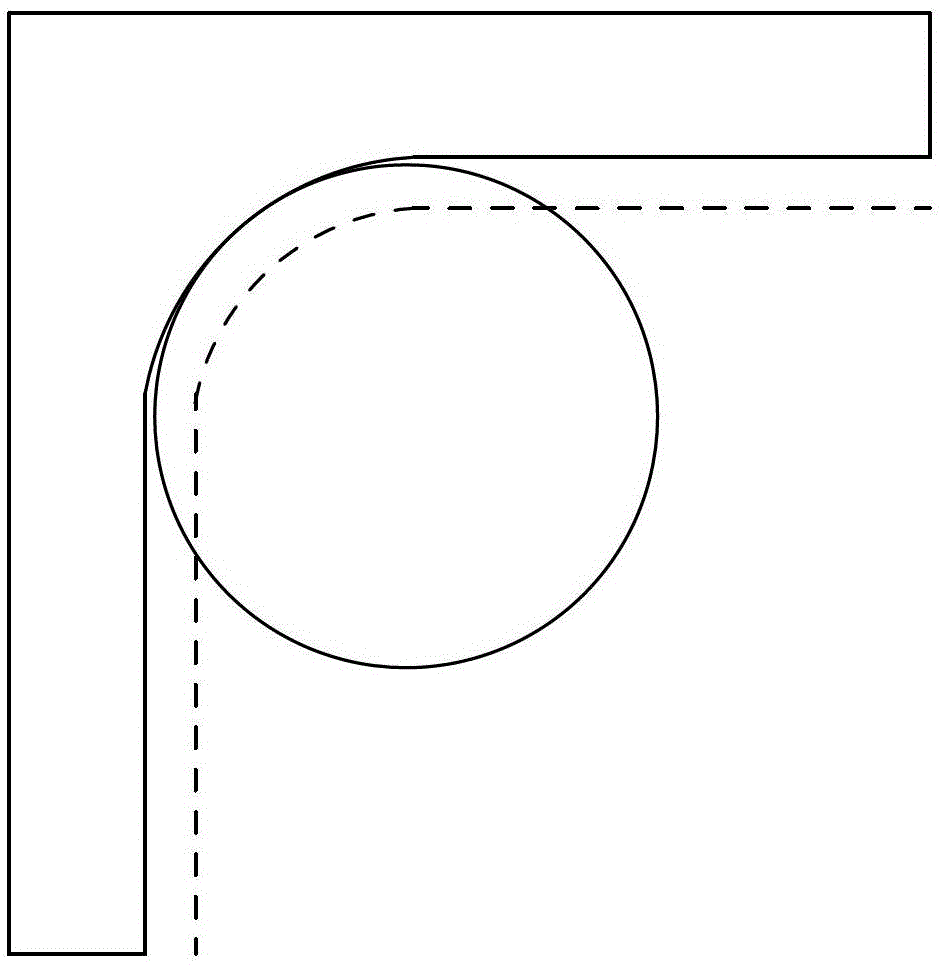

[0019] Such as image 3 As shown, it is a schematic diagram of using the D50R6 tool to contact the workpiece, Figure 4 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com