Waste-removing cutter device of roller cutter

A technology of knife device and roller knife, which is applied in metal processing and other directions, can solve the problems of limited flattening speed, increased time and labor costs, and difficult waste of materials, so as to improve efficiency, save time and manpower, and improve automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

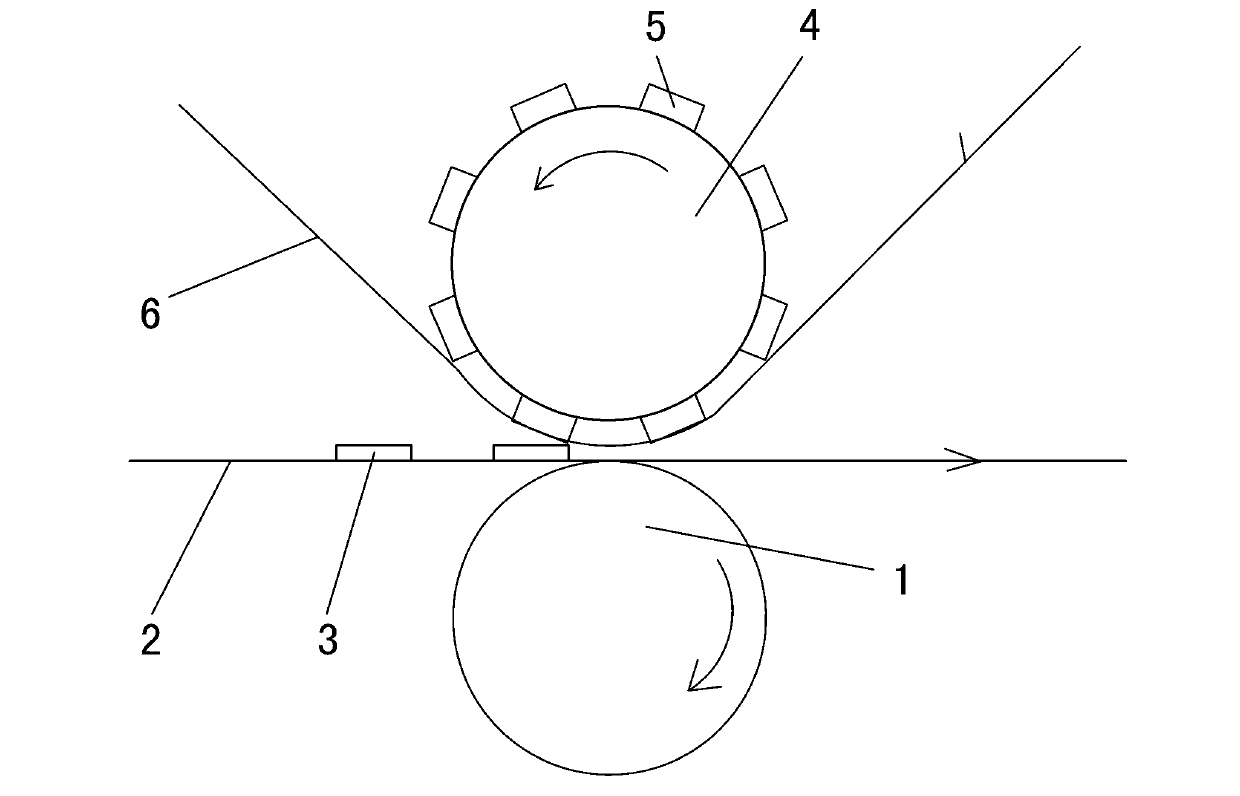

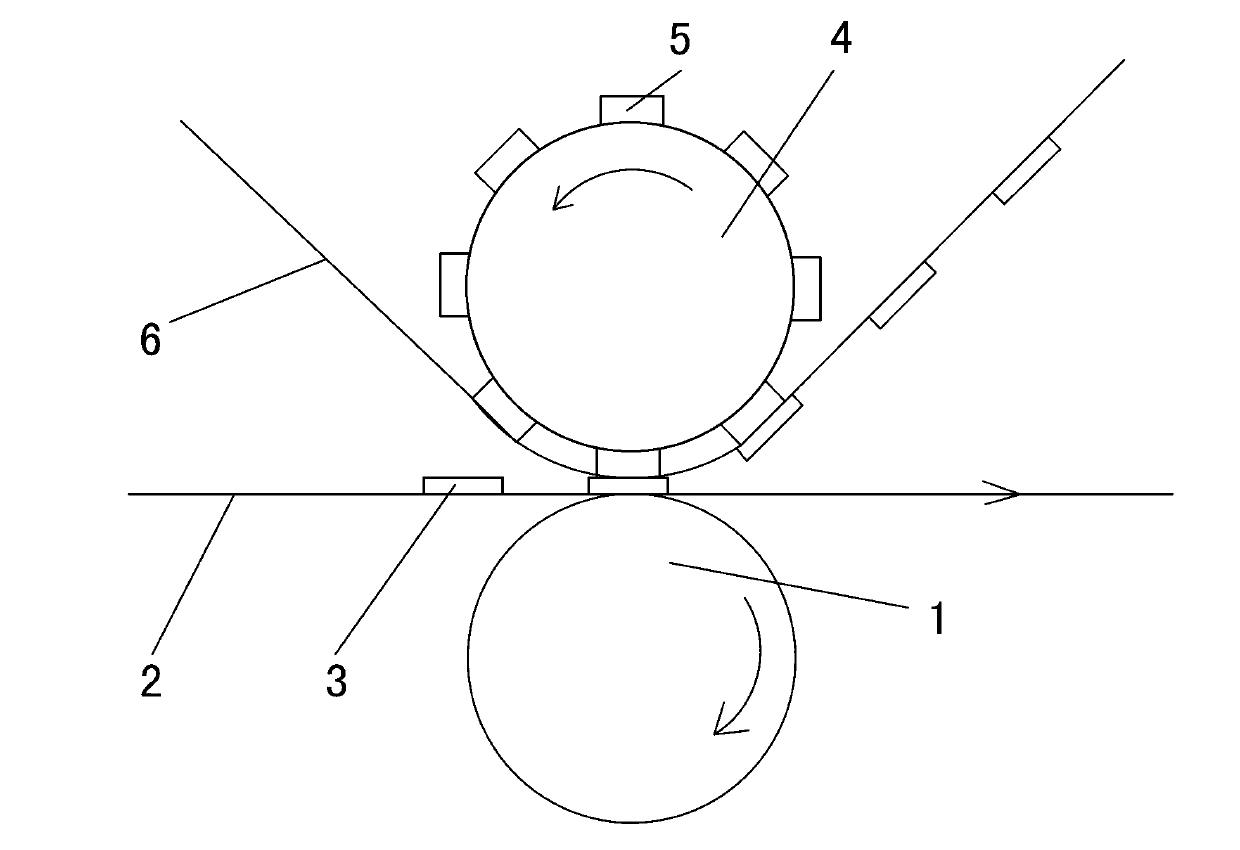

[0014] Such as figure 1 and figure 2 As shown in the figure, a roller knife lifting waste knife device includes a conveyor belt (2) driven by a roller shaft (1), and waste materials (3) and products are placed on the conveyor belt (2) in order and evenly distributed, and It includes a waste lifting knife (4) located above the conveyor belt (2), and a bump (5) is provided on the outer surface of the waste lifting knife (4), and the position of the bump (5) corresponds to the position of the waste (3) setting, the bump (5) drives the running tape (6), the tape (6) runs in the same direction as the conveyor belt (2), the rubber surface of the tape (6) is downward, and the roller shaft (1) and the waste lifting When the knife (4) rotates, it drives the conveyor belt (2) and the adhesive tape (6) to run, and after the bump (5) is pressed against the waste material (3), the adhesive tape (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap