Feeding device of packaging machine

A packaging machine and blanking technology, which is applied in the direction of packaging, etc., can solve the problems of lax sealing, dislocation or distortion of the opening of the packaging bag, distortion and deformation of the opening of the packaging bag, etc., so as to ensure product quality, good position accuracy and Effects of flatness, prevention of misalignment or distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

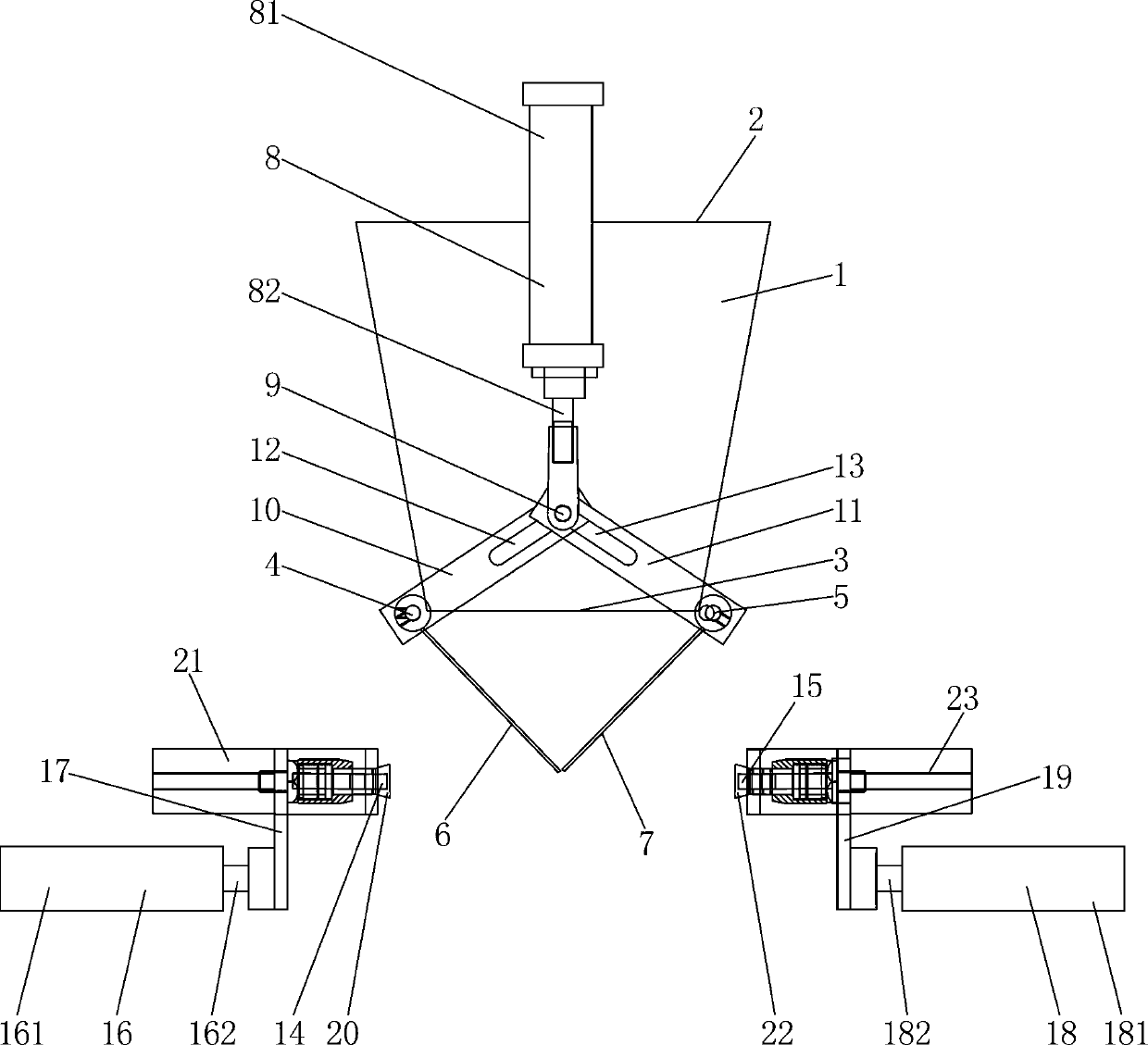

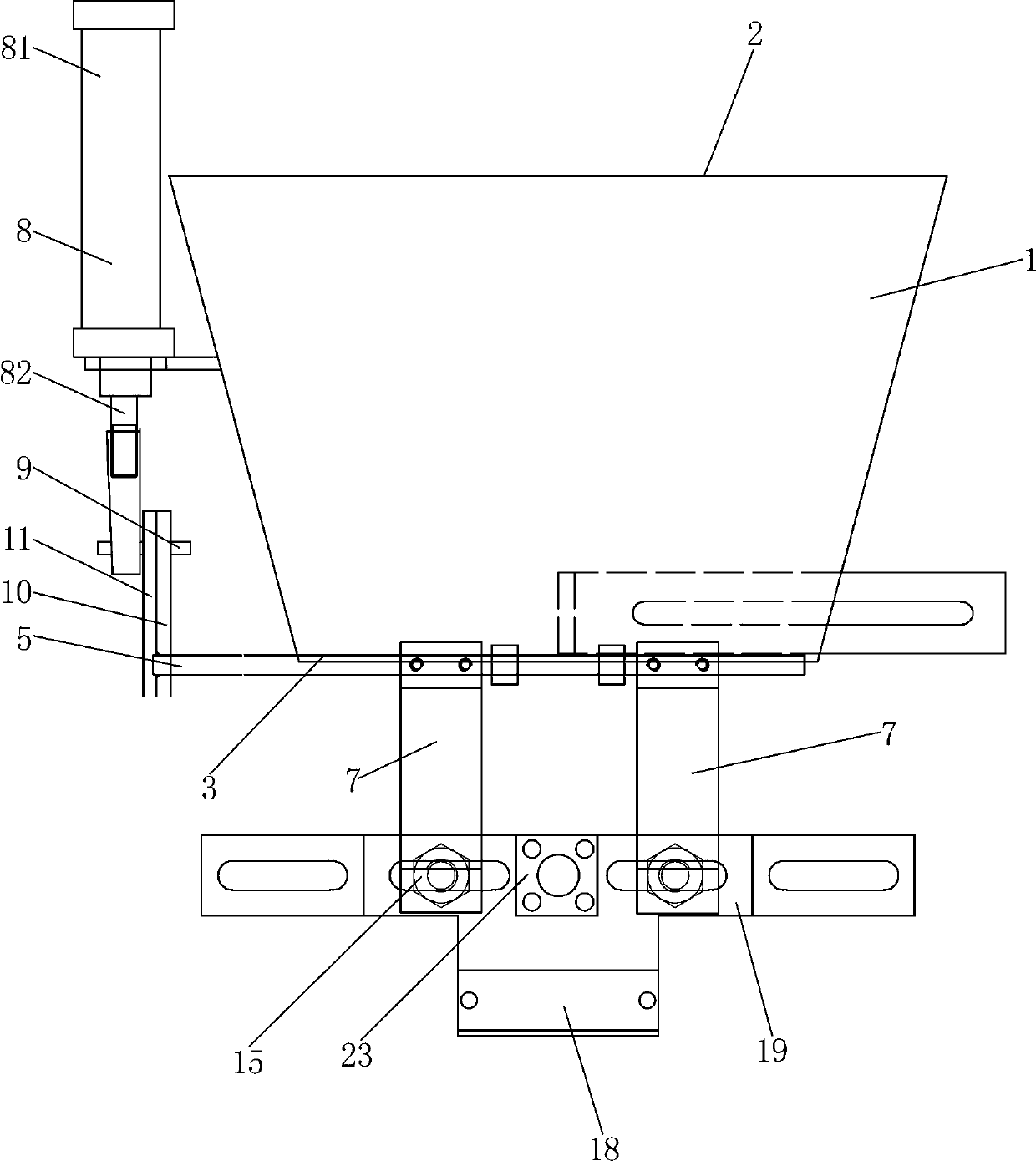

[0021] Such as figure 1 - image 3 As shown, the unloading device of this packaging machine includes a hopper 1, a pocket opening mechanism, a pocket opening pressing mechanism and a pocket opening adsorption opening mechanism.

[0022] The upper end of the hopper 1 is provided with a material inlet 2, and the lower end of the hopper 1 is provided with a material outlet 3.

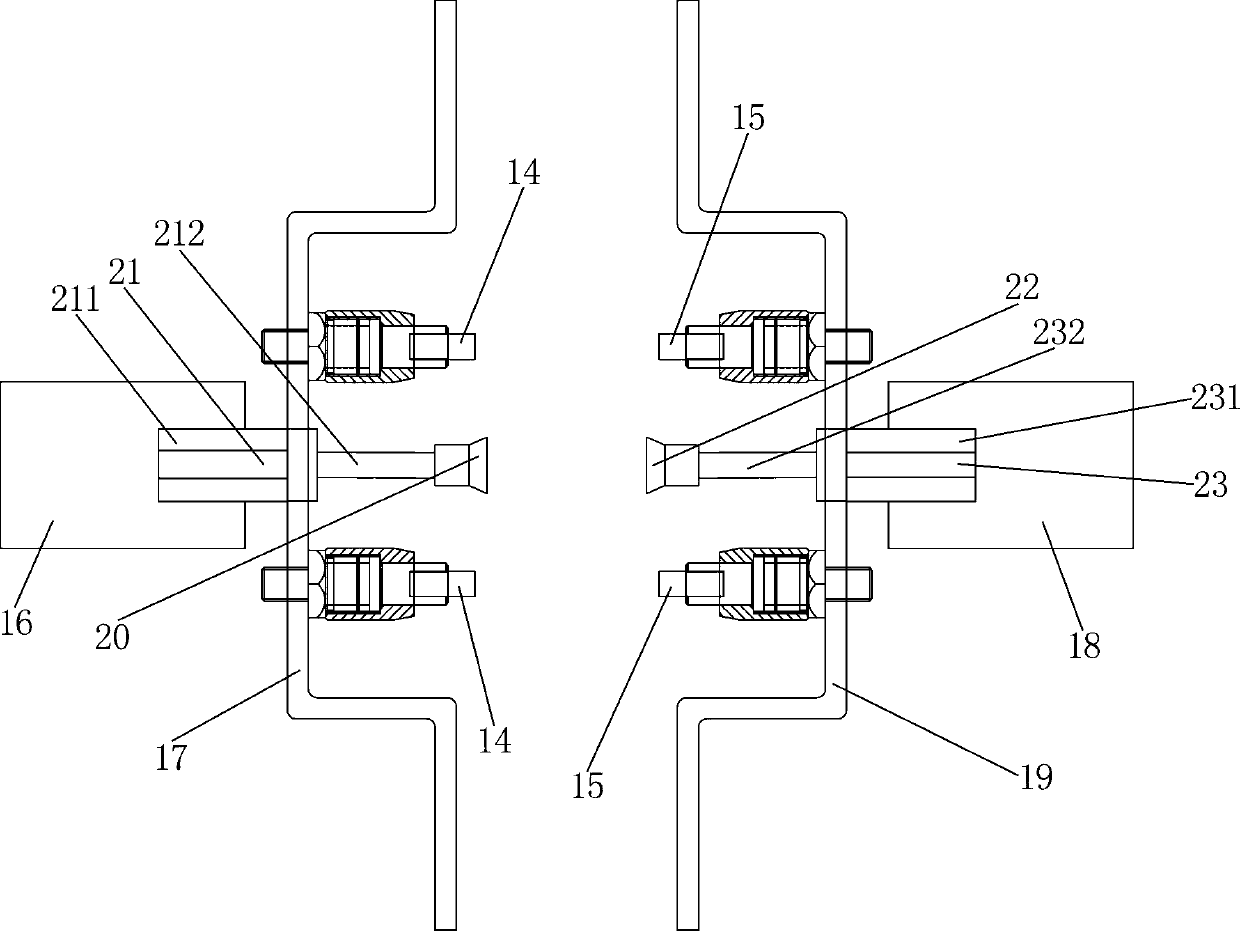

[0023]The opening mechanism of the pocket includes a left rotating shaft 4, a right rotating shaft 5, two left movable pieces 6, two right movable pieces 7 and a driving mechanism for the movable pieces. The left rotating shaft 4 is rotatably installed on the left edge of the hopper outlet 3, the upper end of the left movable piece 6 is connected to the left rotating shaft 4, and there is a gap between the two left movable pieces 6; the right rotating shaft 5 is rotatably installed on the side of the hopper outlet 3 On the right edge, the upper end of the right movable piece 7 is connected to the right r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com