Cigarette carton packaging case and manufacturing process thereof

A technology for packing boxes and cigarettes, which is applied in packaging, transportation and packaging, and other household appliances, etc. It can solve the problems of cutting the edge of the plate, cutting the hands, uneven force, and the detachment of the rib structure to achieve high processing efficiency. , high yield rate, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

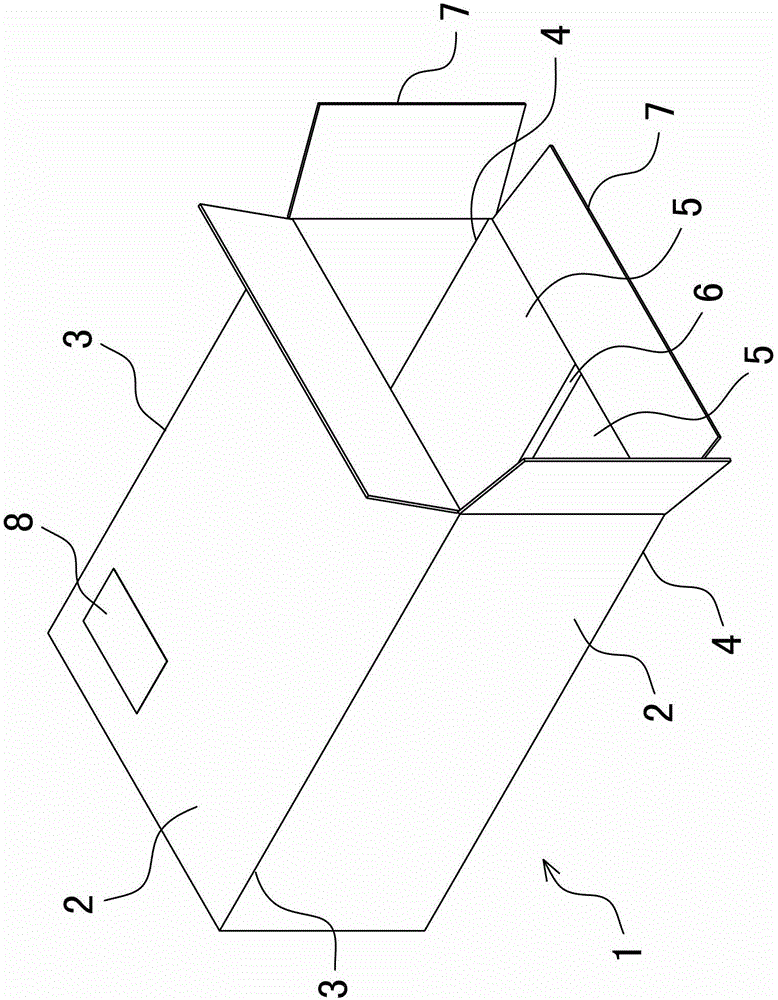

[0032] Example: see attached Figure 1~3 As shown, a cigarette packaging box has a box body 1, and the box body 1 is composed of four side panels 2;

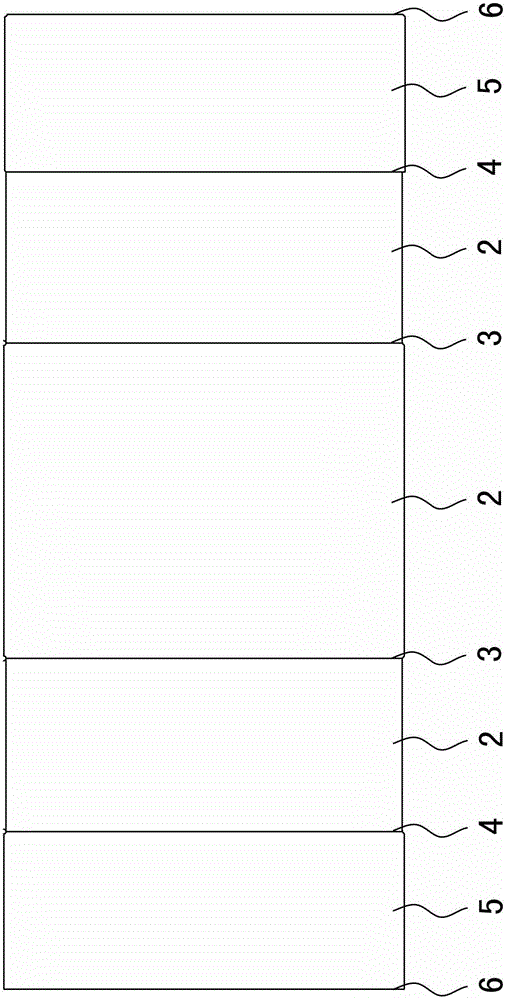

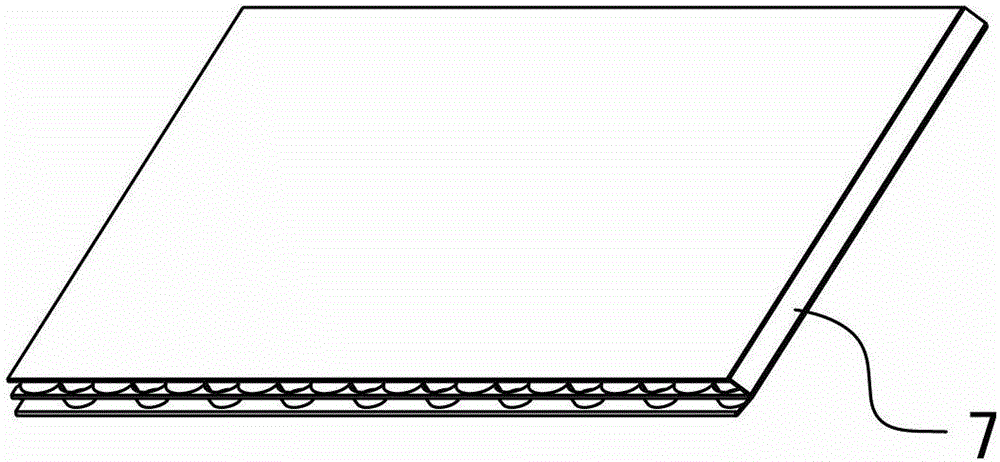

[0033] The box body 1 is integrally folded from a plane plate and has four folded edges, wherein the two first folded edges 3 in the middle define three adjacent side panels 2 forming the box body 1, and the outer sides are located at the The two second folded edges 4 of the first and the end of the plane plate define the left and right halves forming the fourth side panel 5; Surface 6, through which the welding surface 6 is welded and fixed to form the fourth side panel 5, and then the entire box body 1 is formed;

[0034] The box body 1 is provided with an RFID tag 8 to wirelessly transmit a coded signal, the coded signal including the information of the goods in the box. And the planar board is a high-strength plastic honeycomb board.

[0035] Such as Figure 1~6 Shown, a kind of manufacturing process of cigarette packing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com