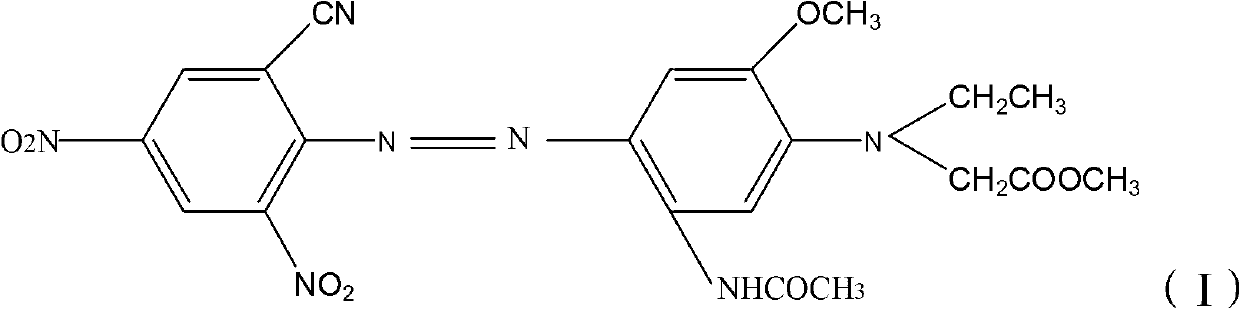

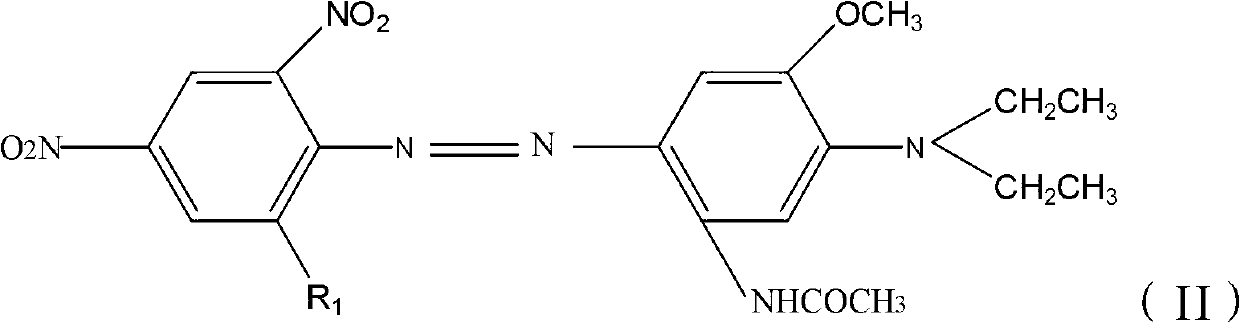

Disperse blue dye composition and disperse blue dye and preparation method and application thereof

A dye composition, disperse blue technology, applied in dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of heavy staining of spandex, unable to meet customers, and the advantages of washing fastness are not obvious, and achieve low staining. , the effect of high washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0024] According to the ratio shown in Table 1, component A, component B, additives and an appropriate amount of water were mixed, ground, and spray-dried to obtain a composite disperse dye.

[0025] Table 1

[0026]

[0027] Use 0.1 g of the disperse dyes prepared in Examples 1-6, together with 10 g of polyester-spandex textile fibers and 99.9 g of water, adjust the pH of the dyeing bath to 4~5 with acetic acid, and heat up to 130° C. within 35 minutes. Keep warm for 30 minutes, cool to 80°C, take it out, and carry out post-treatment according to GB / T2394-2006 standard to obtain a blue textile material, and then carry out setting treatment at 190°C for 45 seconds. Measure its washing fastness to acetate, cotton, nylon, polyester, acrylic and wool according to AATCC61 2A method 95 degree standard.

[0028] Table 2

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com