Conductive textile and its making method

A production method and technology for textiles, which are applied in textiles, papermaking, fiber processing, etc., can solve problems such as low conversion rate, and achieve the effects of low cost, low cost, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

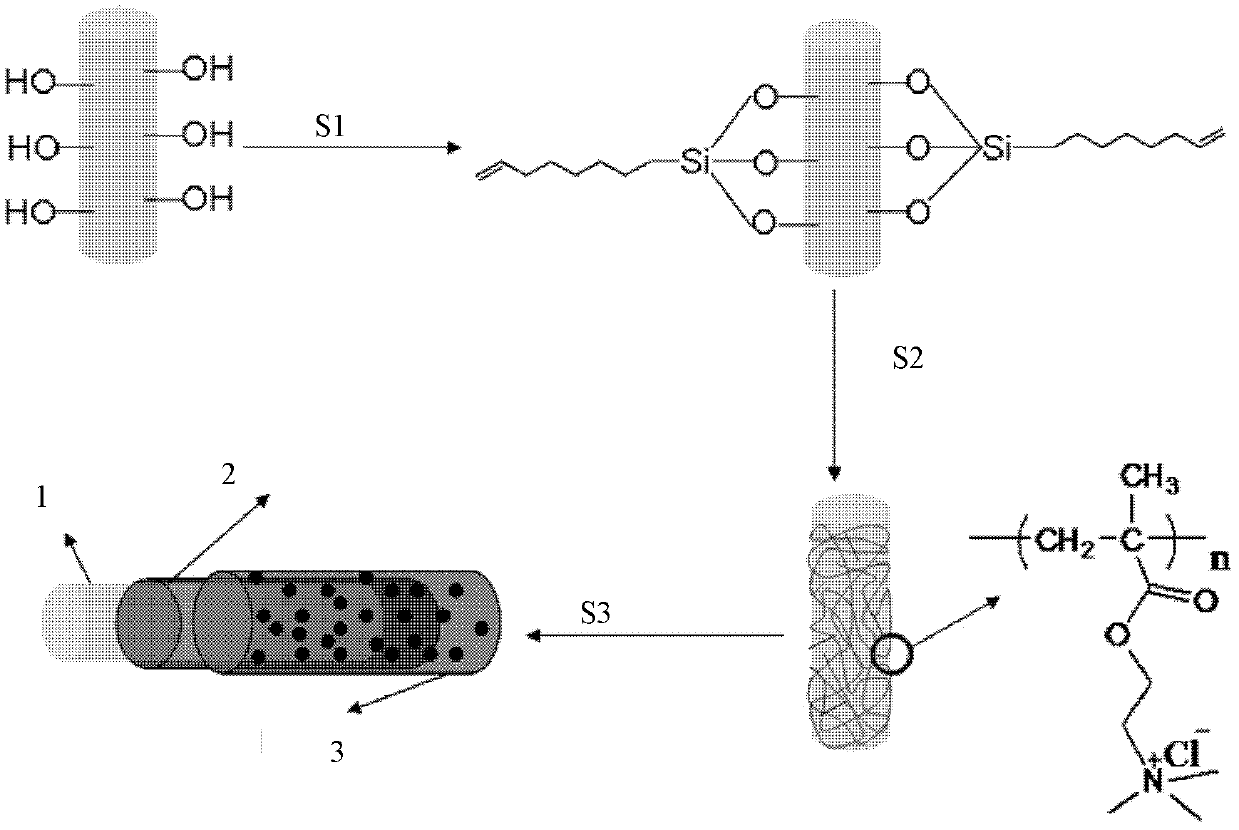

[0030] The present invention describes a general and facile method for the preparation of conductive textiles, such as fibers, yarns, fabrics and films, by a dip-dry-cure process using an in situ radical polymerization method under mild conditions in Deposition of conductive groups on fibers, yarns, fabrics and films, using polyelectrolytes as an adhesive layer. The resulting product still has strong mechanical and electrical stability and functional properties after multiple rubbing-stretching-washing treatment cycles.

[0031] Lightweight, flexible, reliable and wearable electronic components (fibers, yarns, fabrics and films) have a major impact on the development of many applications, including wearable displays, solar cells, drives, data manag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com