Method for prepressing single large-tonnage temporary steel pipe support and then resisting beam bottom during dismantling bridge beam body, and device thereof

A steel pipe support, large tonnage technology, applied in bridges, bridge maintenance, bridge reinforcement and other directions, to achieve the effect of saving stacking costs, easy control, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

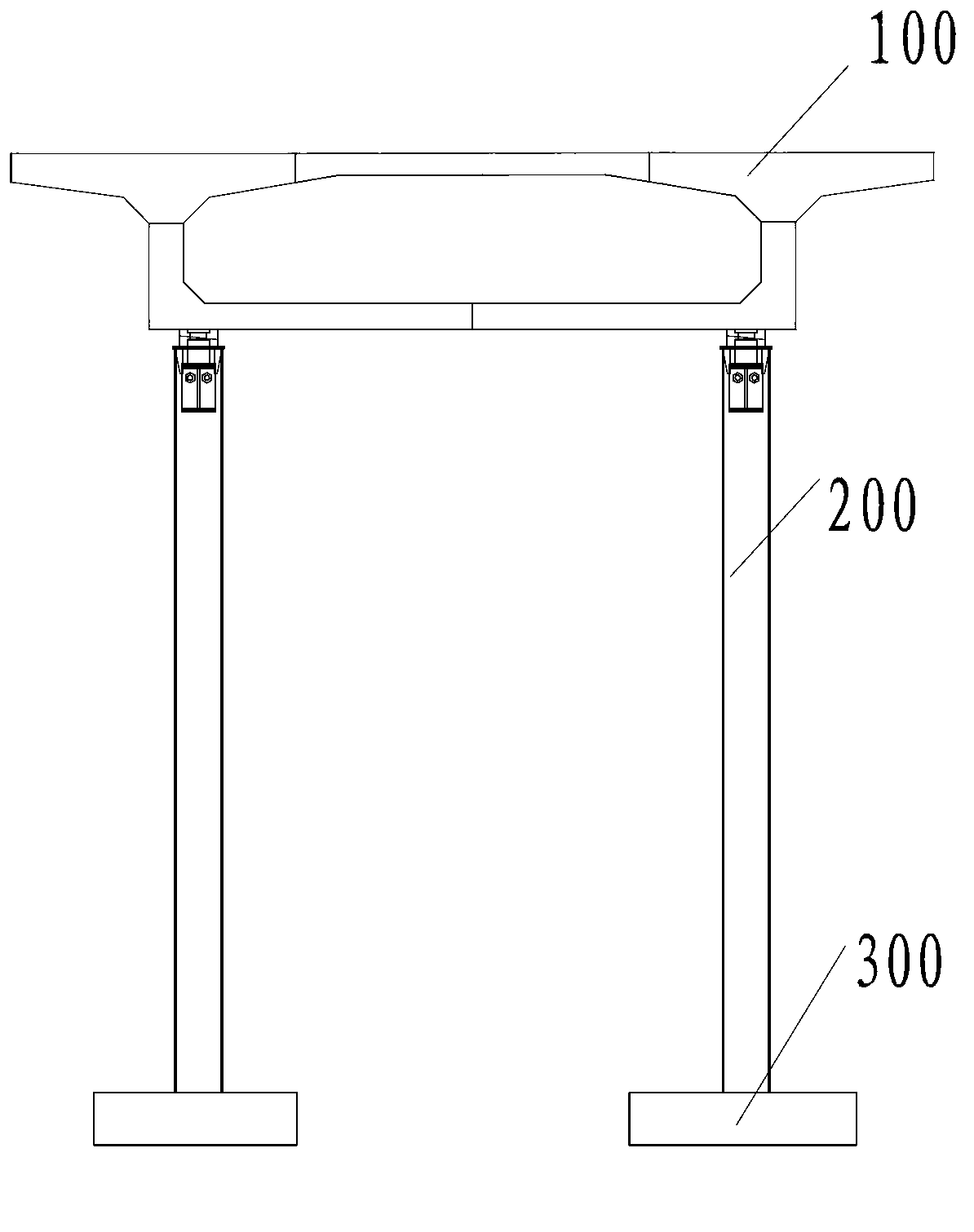

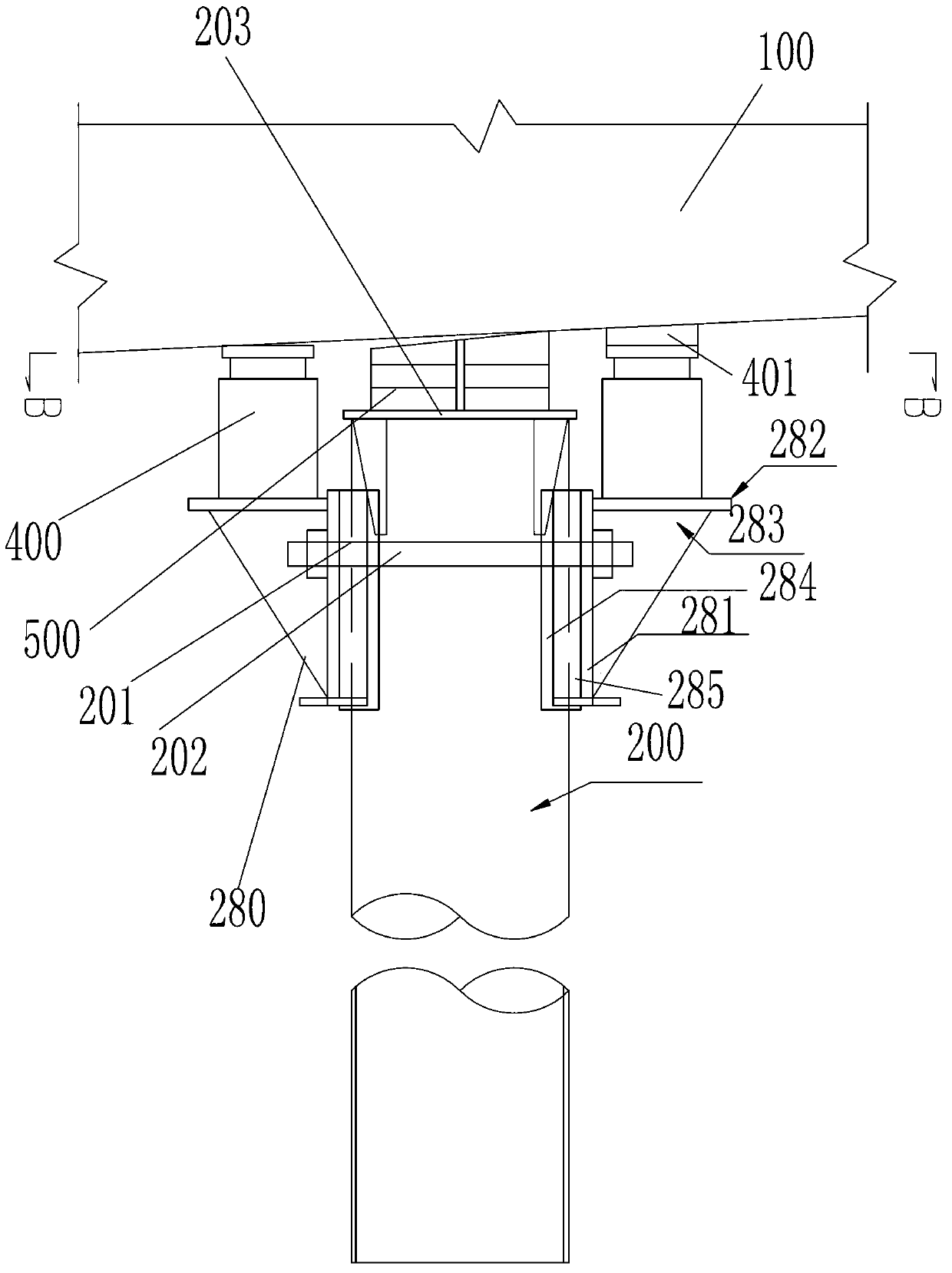

[0032] Such as figure 1 As shown, the layout of the bridge beam body 100 and the temporary support steel pipe 200, the label 0#~19# in the bridge beam body 100 in the figure represents 20 beam sections of the bridge beam body 100; multiple temporary supports are arranged along the 20 beam sections The steel pipe 200 and the support steel pipe 200 are arranged on the concrete strip foundation 300, and the upper part of the support steel pipe 200 is provided with a pre-loaded jacking structure. Two bracket steel pipes 200 are arranged in the same section, such as figure 2 shown.

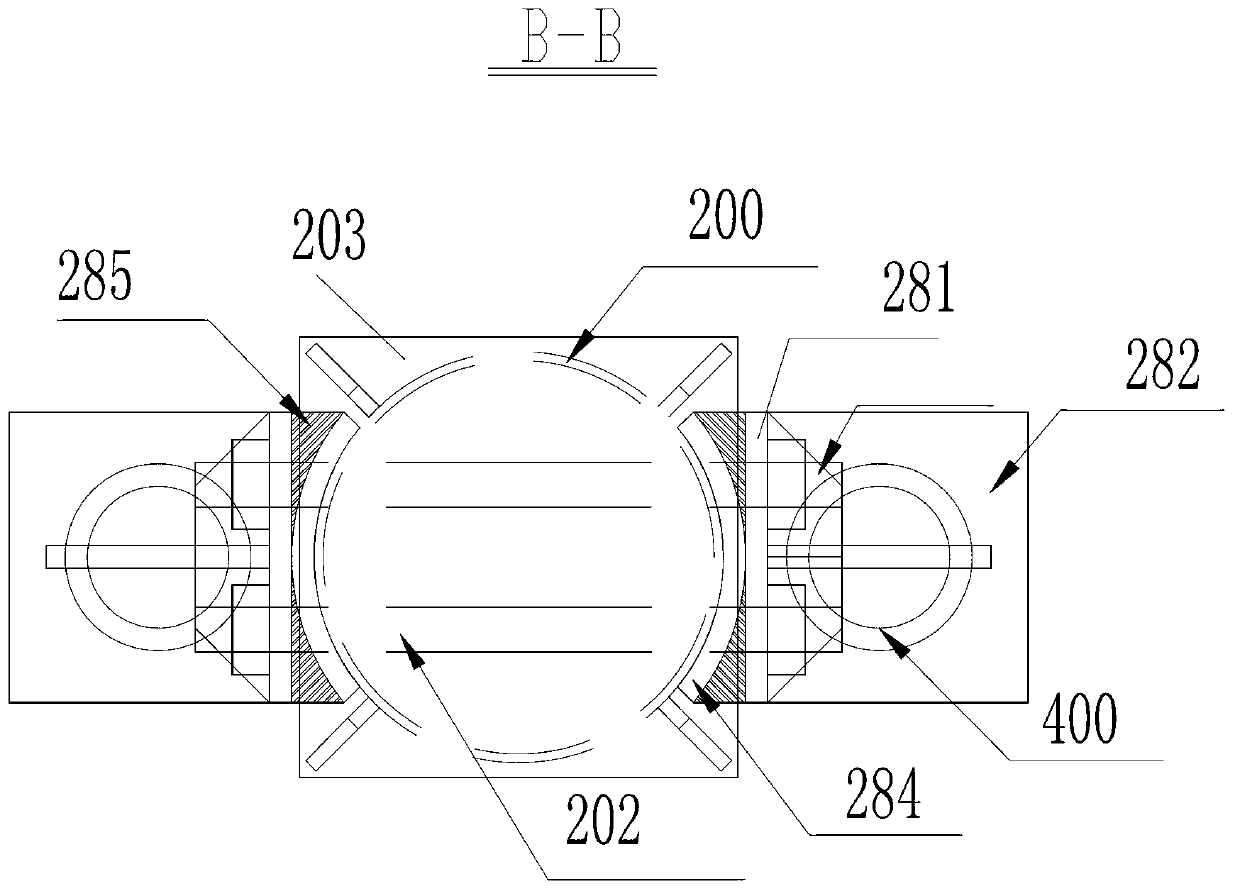

[0033] The steel pipe preloading and tightening device for the large tonnage temporary support at the bottom of the beam is as follows image 3 As shown, the upper part of the support steel pipe 200 is 20 to 50 cm below the top surface of the support steel pipe 200 (the flange plate at the top of the steel pipe), and a connecting hole 201 is opened opposite to each other. Two corbels 280. The two ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap