Early warning hydraulic prop device

A technology of hydraulic props and hydraulic cylinders, applied in props/supports, mining equipment, earthwork drilling and mining, etc., can solve problems such as short service life of hydraulic systems, hydraulic system damage, internal leakage, etc., to reduce life safety accidents and prevent dumping accidents , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below through preferred embodiments in conjunction with the accompanying drawings.

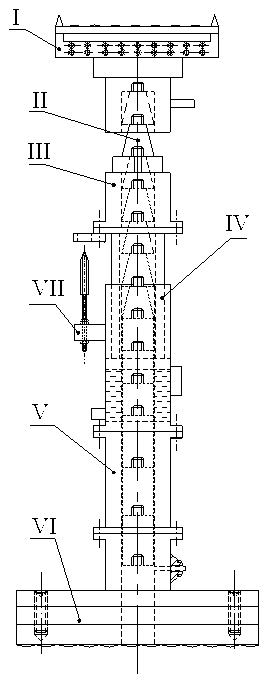

[0047] Such as figure 1 As shown, the device of the present invention is transported in the tunnel, and according to the rock formation situation, the optional damping layer facing the triangle is a slope of 3%-4%, adapting to the inclined situation of the rock formation;

[0048] Such as Figure 6 As shown, according to the actual support height of the tunnel, fasten the length of the pillar body II, and tighten the mechanical chuck III by using a torque wrench to clamp the lead screw so that the clamping claws of the mechanical chuck clamp the tight cone 15;

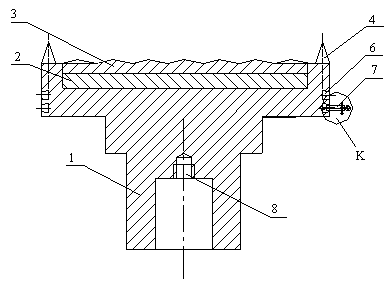

[0049] Such as Figure 12 As shown, the liquid is injected into the clamping liquid inlet 45 through the hydraulic pump, and the liquid is returned to the loosening liquid inlet 44, so that the clamping claws 37 of the hydraulic spring chuck slightly touch the microcone 16, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com