Intelligent defrosting control method for parallel multiple on-line unit with multiple compressors

A control method and multi-compressor technology, which are applied in heating and ventilation control systems, refrigerators, heating methods, etc., can solve the problems of complex multi-compressor parallel and multi-connection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

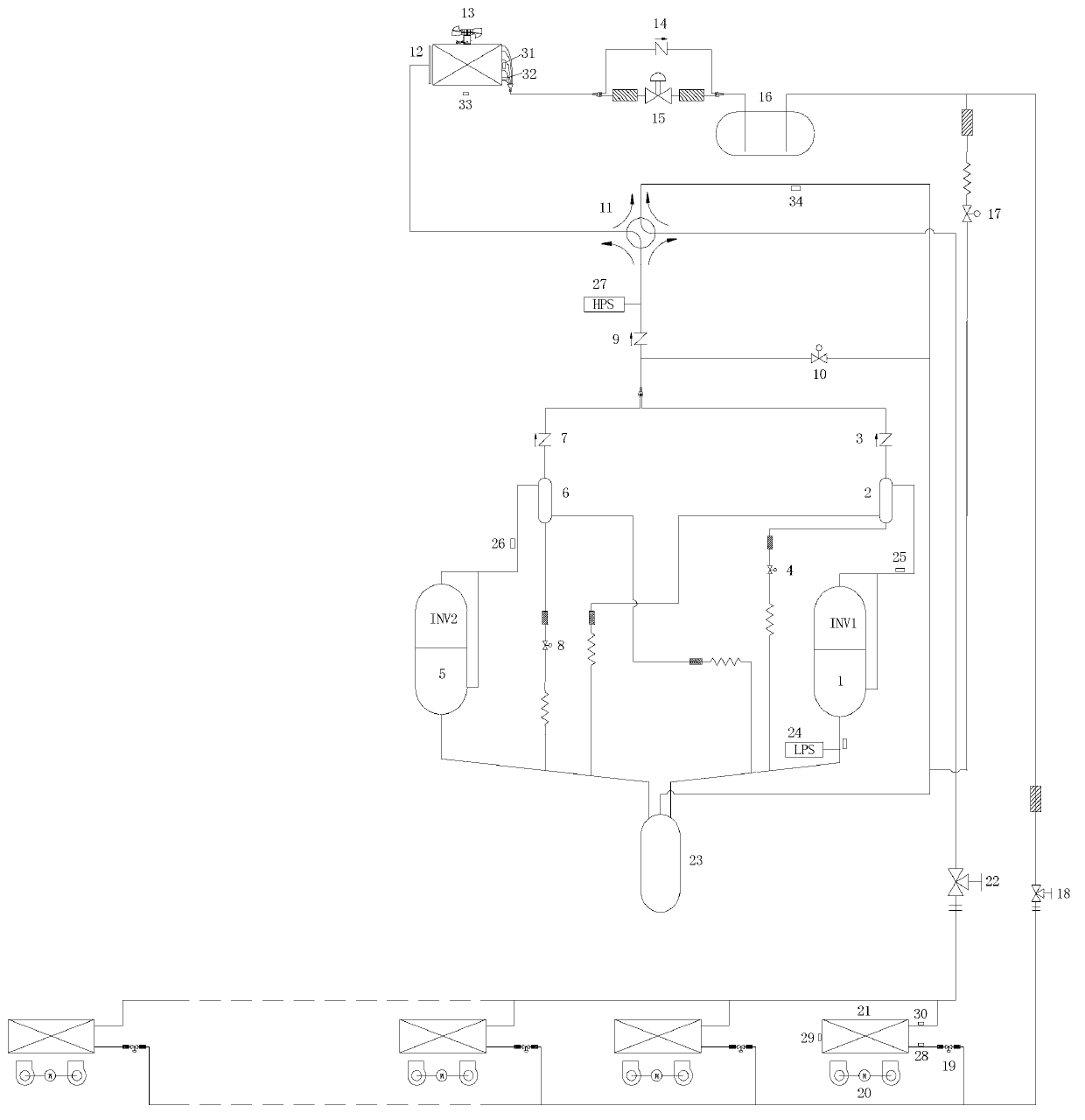

Image

Examples

example 1

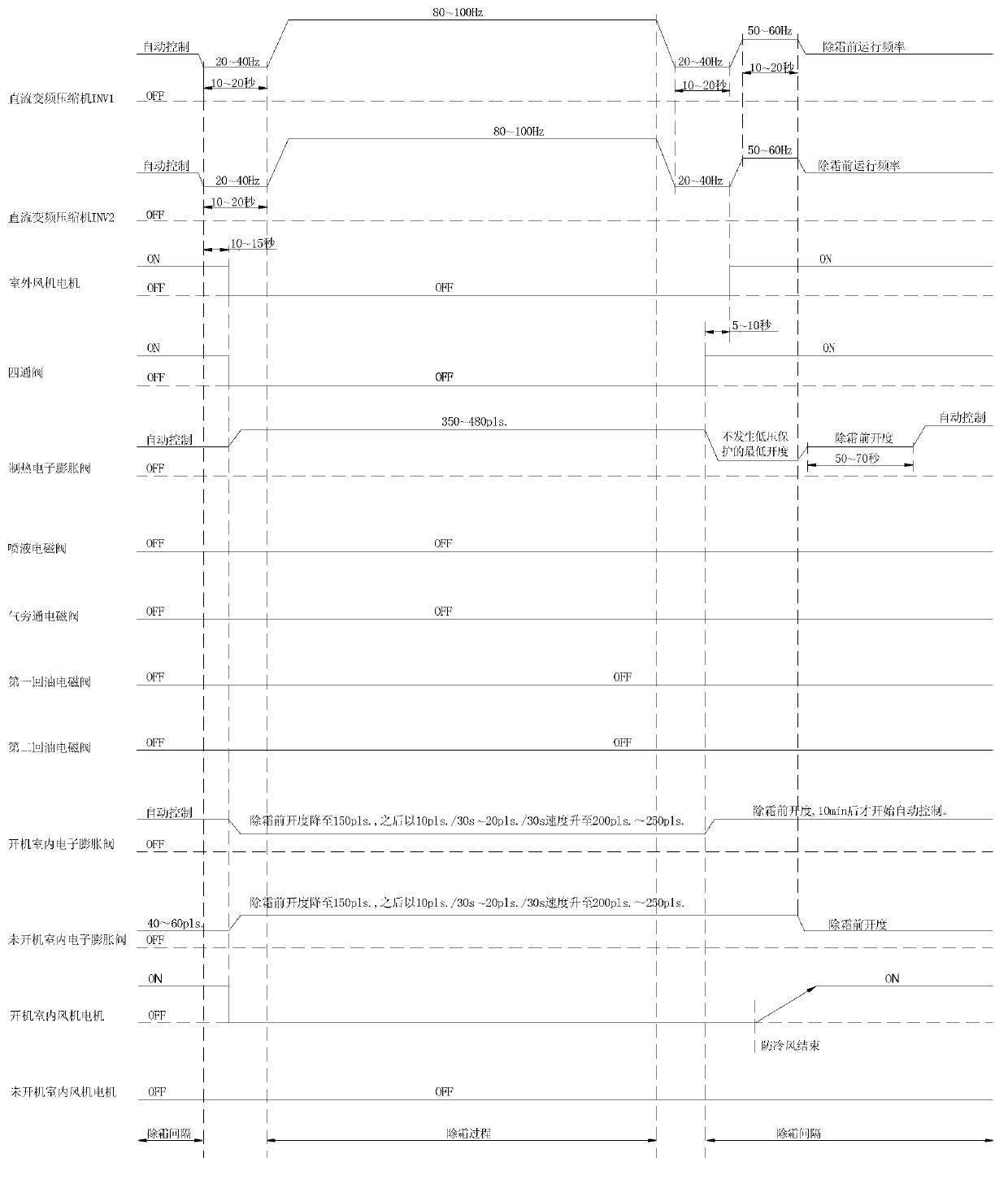

[0028] (1) When the multi-split machine is running in heating mode, when it runs continuously for 30 minutes and meets the following conditions for 3 minutes, the outdoor electric control system will issue a defrosting command: if the outdoor ambient temperature detected by the outdoor temperature sensor is ≤0°C, And when the defrosting temperature detected by the defrosting temperature sensor 32 is ≤0.8×outdoor ambient temperature -10°C;

[0029] (2) After the first DC inverter compressor 1 receives the defrosting command, the operating frequency drops to 30Hz and runs for 20 seconds, then the operating frequency rises to 80Hz to start the defrosting process;

[0030](3) After the second DC variable frequency compressor 2 receives the start instruction, the operating frequency drops to 30Hz and runs for 20 seconds, then the operating frequency rises to 80Hz to start the defrosting process;

[0031] (4) During the defrosting process of the first DC inverter compressor 1 and th...

example 2

[0042] (1) When the multi-connected unit is running in heating mode, when the continuous operation is 30 minutes and the following conditions are met for 2 minutes, the outdoor electric control system will issue a defrosting command: if the outdoor ambient temperature detected by the outdoor temperature sensor 33 is >0°C , and when the defrosting temperature detected by the defrosting temperature sensor 32 is ≤0.2×outdoor ambient temperature -10°C;

[0043] (2) After the first DC inverter compressor 1 receives the defrosting command, the operating frequency drops to 30Hz and runs for 15 seconds, then the operating frequency rises to 90Hz to start the defrosting process;

[0044] (3) After the second DC variable frequency compressor 2 receives the start command, the operating frequency drops to 30Hz and runs for 15 seconds, then the operating frequency rises to 90Hz to start the defrosting process;

[0045] (4) During the defrosting process of the first DC inverter compressor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com