Driven disc hub flatness detector and detecting method thereof

A technology of flatness detection and disc hub, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of low efficiency and accuracy of detection, high labor intensity, etc., and achieve the effect of increasing accuracy, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

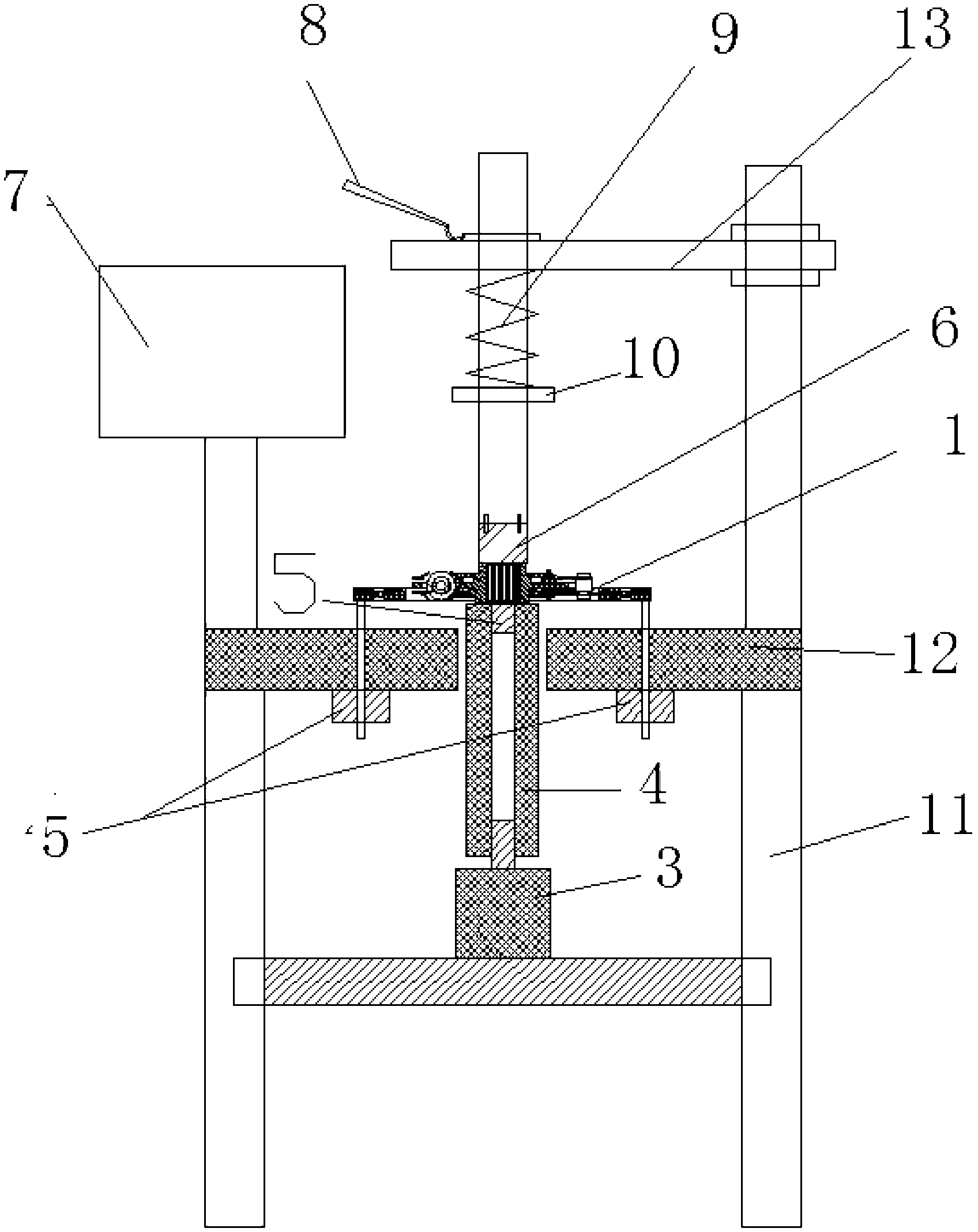

[0017] like figure 1 A driven disk hub flatness detector is shown, comprising a driven disk hub 1, a rotating shaft 4 controlled by a motor 3 and driven to rotate the driven disk hub 1, arranged on the same side of the driven disk hub 1 and At least two or more displacement sensors 5 in contact with the hub, at least two or more displacement sensors 5 are arranged on the same horizontal plane, the lower end of the spline of the driven disk hub 1 is connected to the rotating shaft 4, and the upper end of the spline is above the A lift limit post 6 that can press the disk hub is provided. The inspection machine can also be used for the flatness inspection of the driven disc assembly. The displacement sensor 5 is connected with the controller input, and the controller output is connected with a display 7. The top of the lifting limit post 6 is provided with a wrench 8 to control its lifting, the top of the lifting limit post 6 is socketed with a limit spring 9, and the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com