Step type valve

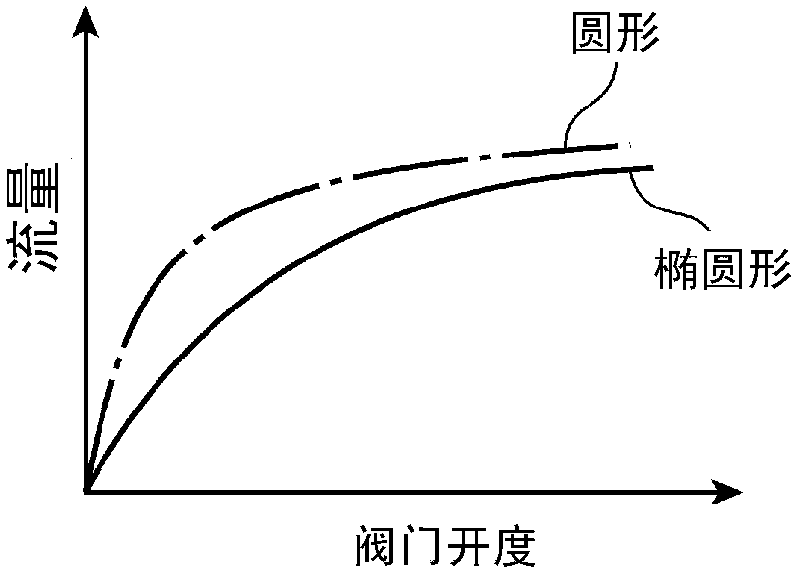

A stepped, valve technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problem of difficult application of high temperature fluid, valve seat leakage, etc., to achieve the effect of suppressing the rising flow, reducing the gap, and not easy to flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

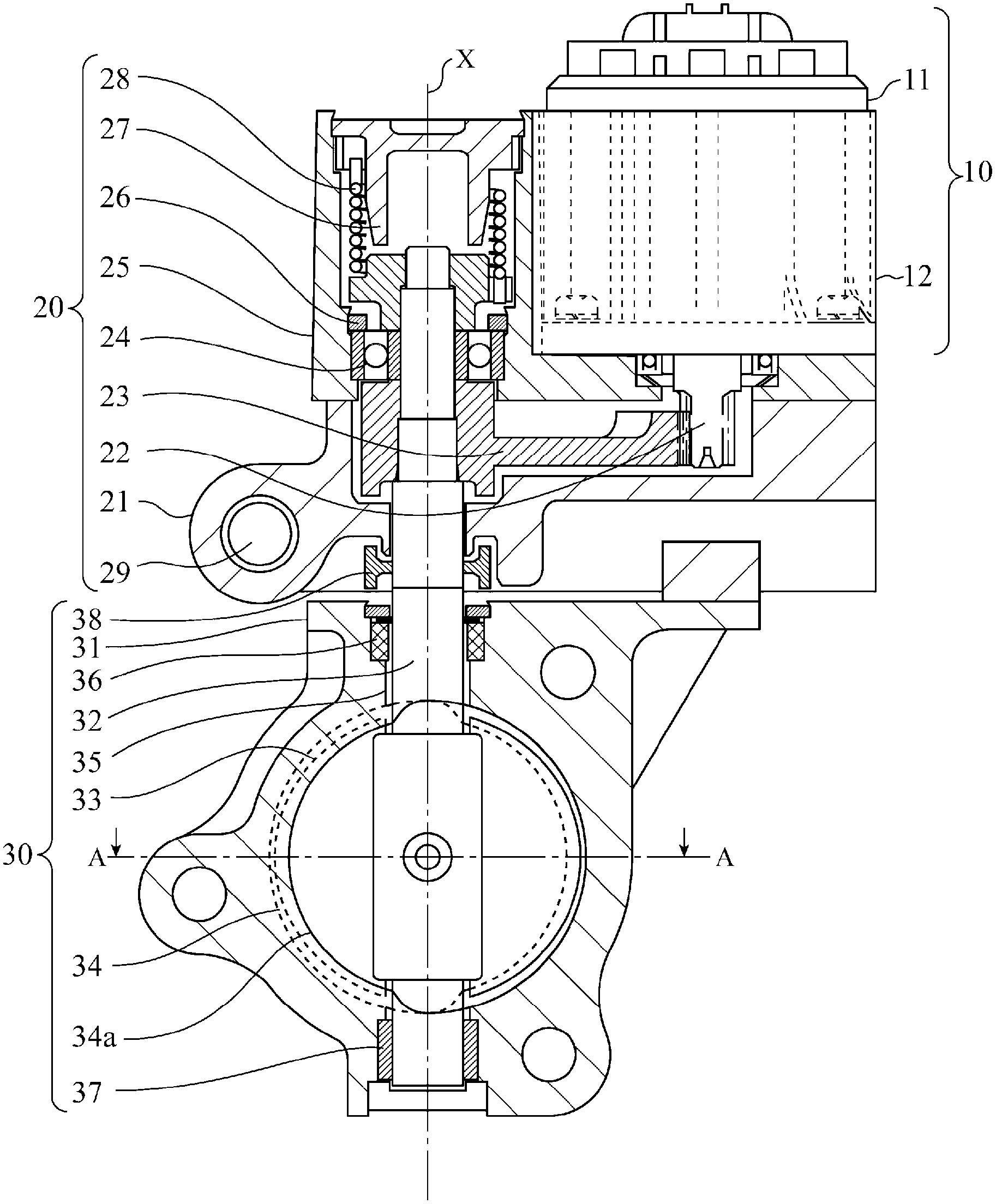

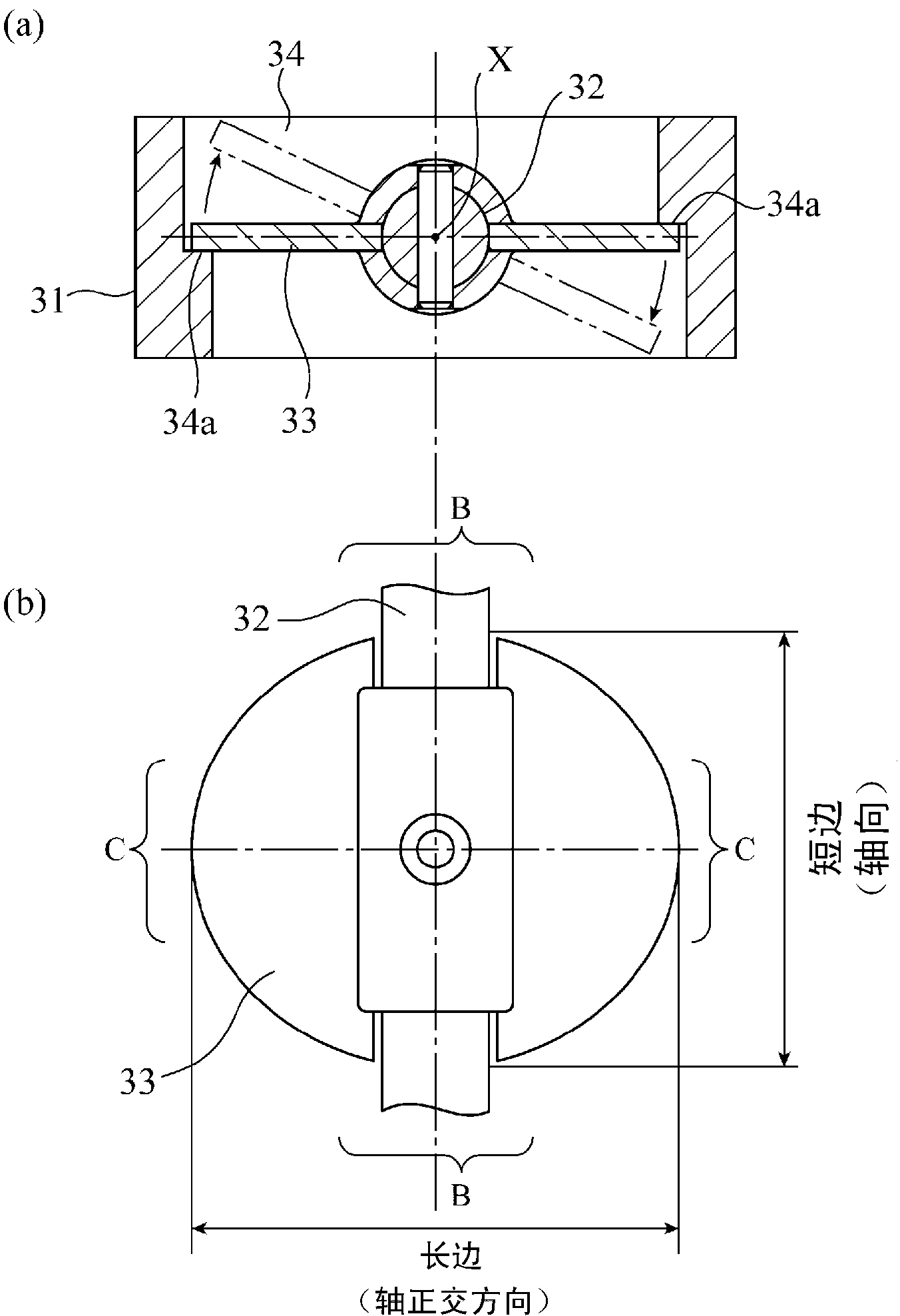

[0021] figure 1 The stepped butterfly valve shown is composed of an actuator portion 10, a gear portion 20, and a valve portion 30. The actuator portion 10 generates a rotational driving force for opening and closing the valve, and the gear portion 20 connects the actuator portion The driving force of 10 is transmitted to the valve shaft 32. The valve portion 30 is provided in a pipe (not shown) through which fluid such as high-temperature gas flows, and opens and closes the valve 33 to control the flow rate of the fluid.

[0022] The actuator section 10 uses a DC motor or the like for the electric motor 11 and covers the electric motor 11 with a heat shield 12. One end of the output shaft of the electric motor 11 is a pinion gear 22 that extends into the gear box 21. When the electric motor 11 is driven forward or reversely, the pinion gear 22 meshes with the gear 23 and rotates, thereby transmitting the driving force of the electric motor 11 to the valve shaft 32. The valve sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com