Banking duck furnace and construction method thereof

A construction method and technology of duck ovens, which are applied in special commodity baking, baking, food science and other directions, can solve the problems of unfavorable oven temperature, oven size, unreasonable space, fast heat dissipation, etc., and achieve a scientific and reasonable space size. , to avoid excessive water loss, the effect of environmental protection and stability of heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

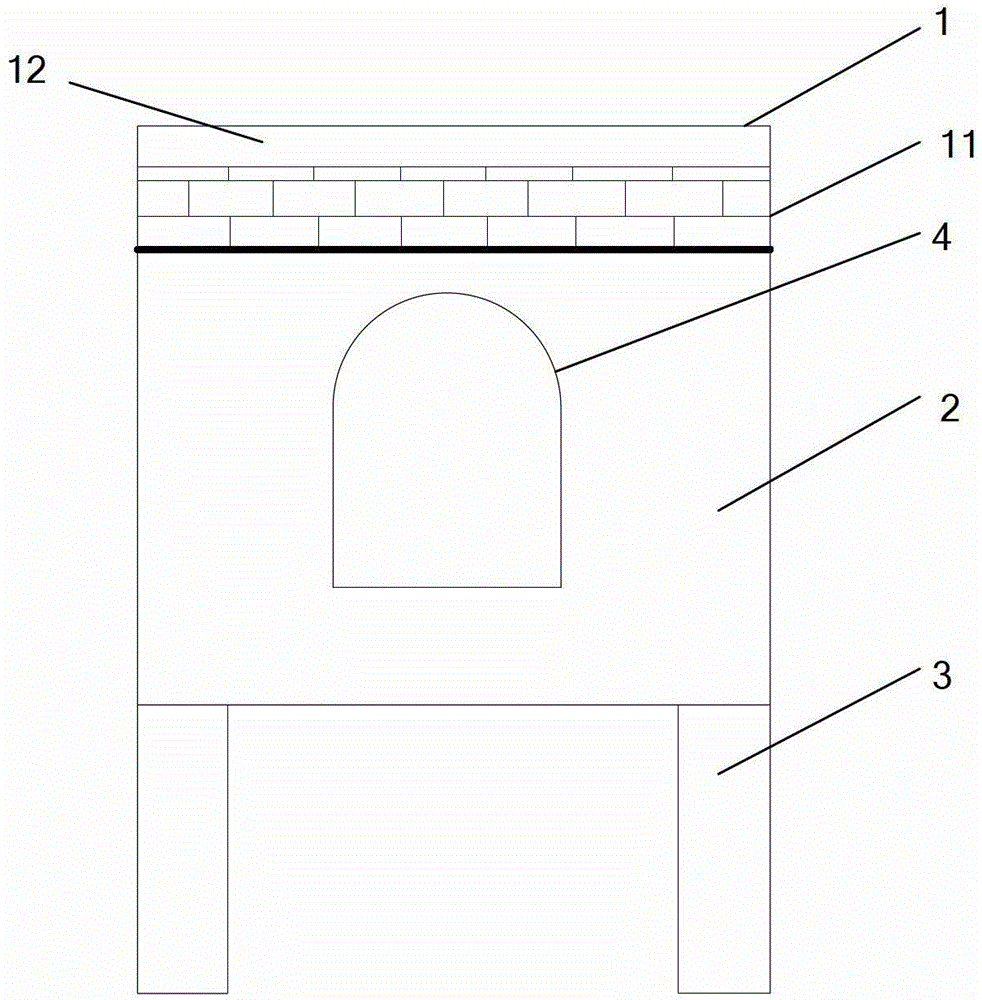

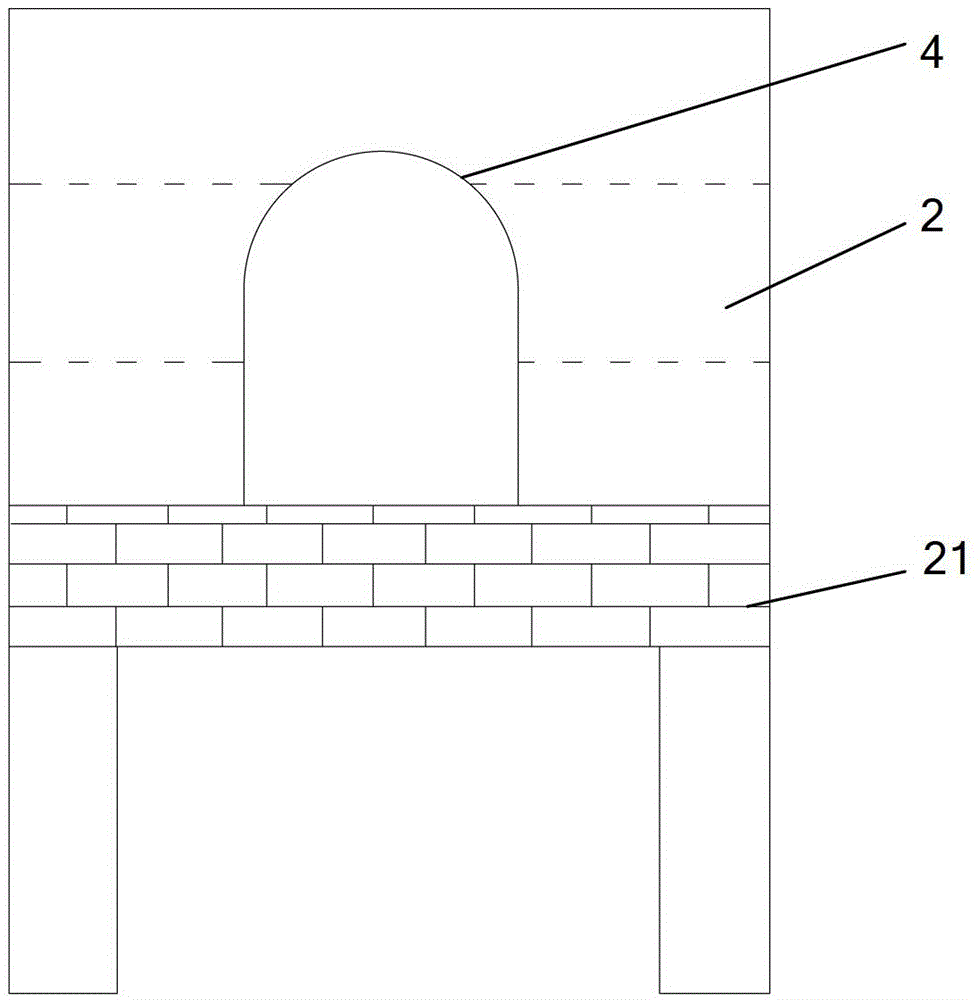

[0050] Such as figure 1 As shown, a stewed duck furnace is mainly composed of a furnace roof 1, a furnace body 2 and a duck furnace base 3. The specific construction process is as follows:

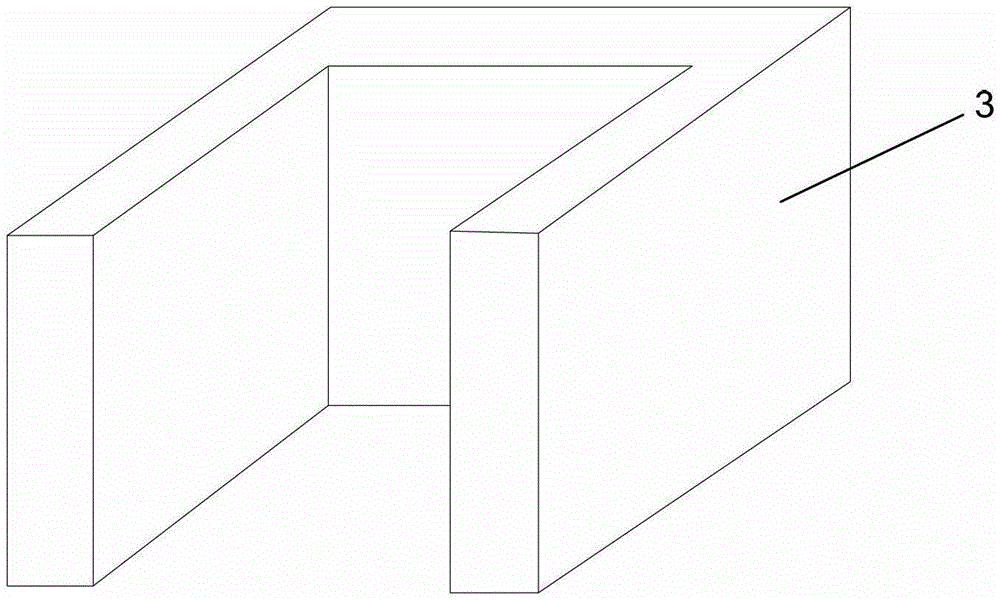

[0051] The first step is to build the duck stove base 3 with three walls, such as figure 1 , 2 Shown, this duck stove base 3 is vacant at the body of heater front. The base 3 of the duck furnace is 2100mm long and 2200mm wide. The three sides are double-layer furnace brick walls. The net distance between the left and right side walls is 1600mm. A total of 11 layers of furnace bricks are built. Find the level when the height of the duck furnace base 3 is 900mm. .

[0052] In the second step, the furnace bottom frame is installed on the duck furnace base 3 . Place the first 1800mm medium angle steel on the back wall, and place four angle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com