Stainless steel bathroom cabinet

A bathroom cabinet, stainless steel technology, applied in home appliances, sanitary equipment, applications and other directions, can solve the problems of long assembly time, uneven force on the cabinet, lack of technical content, etc., to improve the degree of force, the appearance of the cabinet, Assemble the effect of quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

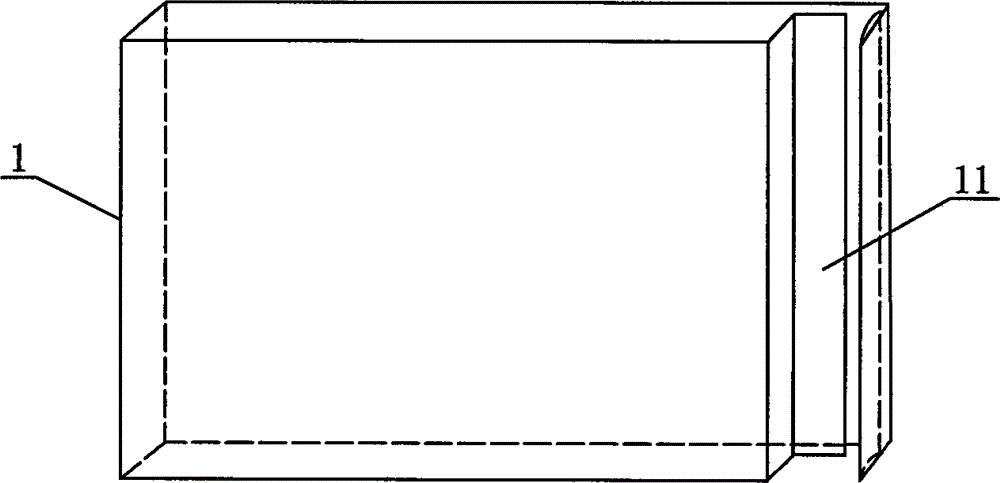

[0026] see Figure 1-Figure 6 , the stainless steel bathroom cabinet, the cabinet body is composed of a side plate 1, a beam 2 and a bottom plate 3, the beam 2 has at least two upper and lower beams, of which there are two beams 2 in this embodiment, which are respectively installed above the rear of the cabinet body and below, the bottom plate 3 is fixedly connected with the lower beam 2 and the side plate 1 respectively, the rear side of the side plate 1 is provided with a first fitting groove 11, and the cross beam 2 is fixedly connected in the first fitting groove 11.

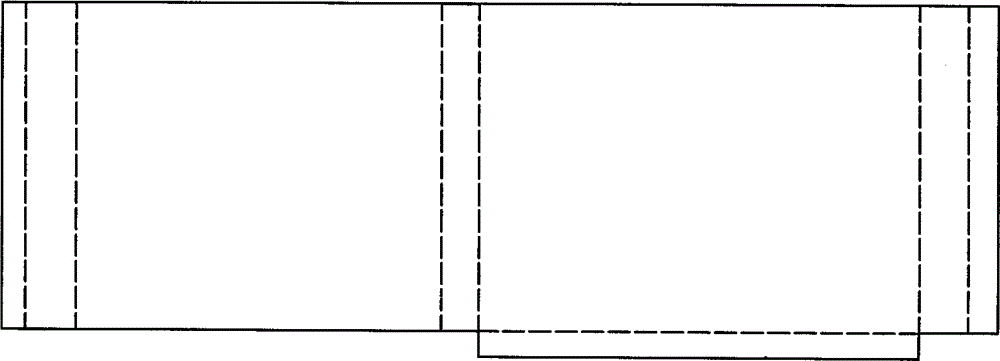

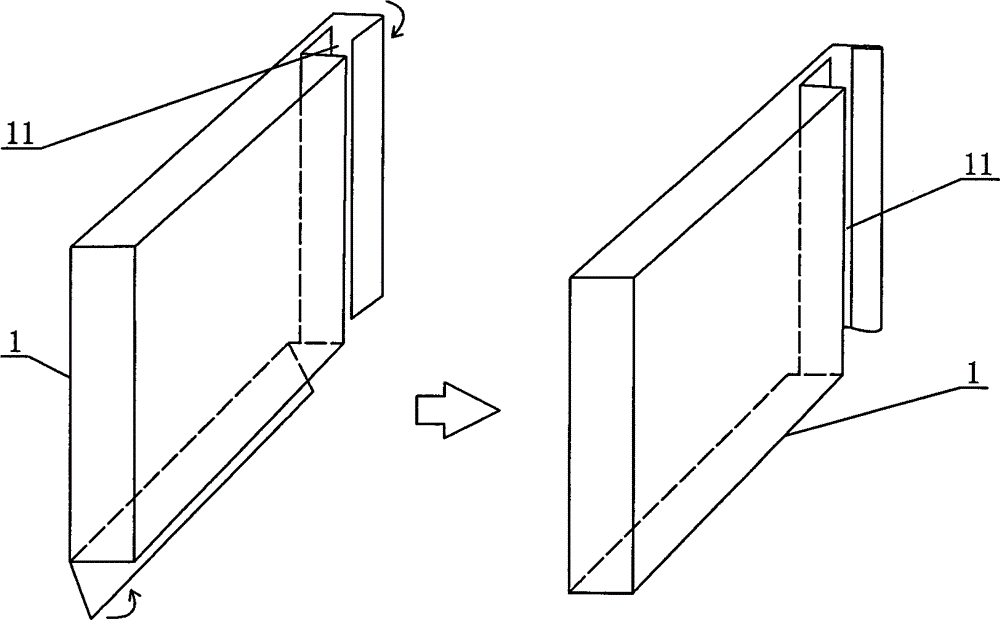

[0027] The side panels 1 are formed by folding strips or plates, and are integrally formed by stamping. Such as image 3 As shown, because the edge of the strip or plate is relatively sharp, in order to prevent it from scratching the hands and speed up the assembly speed of the cabinet, a flanging (no label in the figure) is provided at the edge of the first assembly groove 11; in this embodiment Among th...

no. 2 example

[0032] see Figure 7-Figure 9 , the main difference between this stainless steel bathroom cabinet and the first embodiment is that the bottom of the side plate 1 is provided with a second assembly groove 12, the bottom plate 3 is fixedly connected in the second assembly groove 12, and the edge of the second assembly groove 12 is set There are flanging (no label in the figure). In this embodiment, the bottom plate 3 is directly inserted into the second assembly groove 12 (this assembly method is similar to the method of assembling the beam 2 to the first assembly groove 11, and will not be described in detail), and this assembly method will not reduce the strength of the side plate 1 , but can save steps such as (bottom plate 3 and side plate 1) positioning, further improve the assembly speed of the cabinet, and better reflect the integration and aesthetics of the cabinet, while enhancing the firmness and acceptance of the cabinet.

[0033] Other unmentioned parts are the same...

no. 3 example

[0035] see Figure 10-Figure 11 , the main difference between this stainless steel bathroom cabinet and the first embodiment is that the bottom of the side plate 1 is provided with a second assembly groove 12, the second assembly groove 12 is open to the left and right, the bottom plate 3 can pass through the second assembly groove 12, and then In addition, the rear side of the side plate 1 is no longer provided with the first assembly groove, but the rear side of the side plate 1 can be assembled with the beam. The side panel 1 in this embodiment is generally used to be centrally placed inside the cabinet body, and is essentially the middle panel / partition board of the cabinet body, which is used to divide the cabinet body into multiple cavities to meet the use requirements.

[0036] Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com