Bone screw for fixing osteoporosis bone

A technology for osteoporosis and bone screw, applied in the field of bone screw to achieve the effect of improving health and nutritional status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

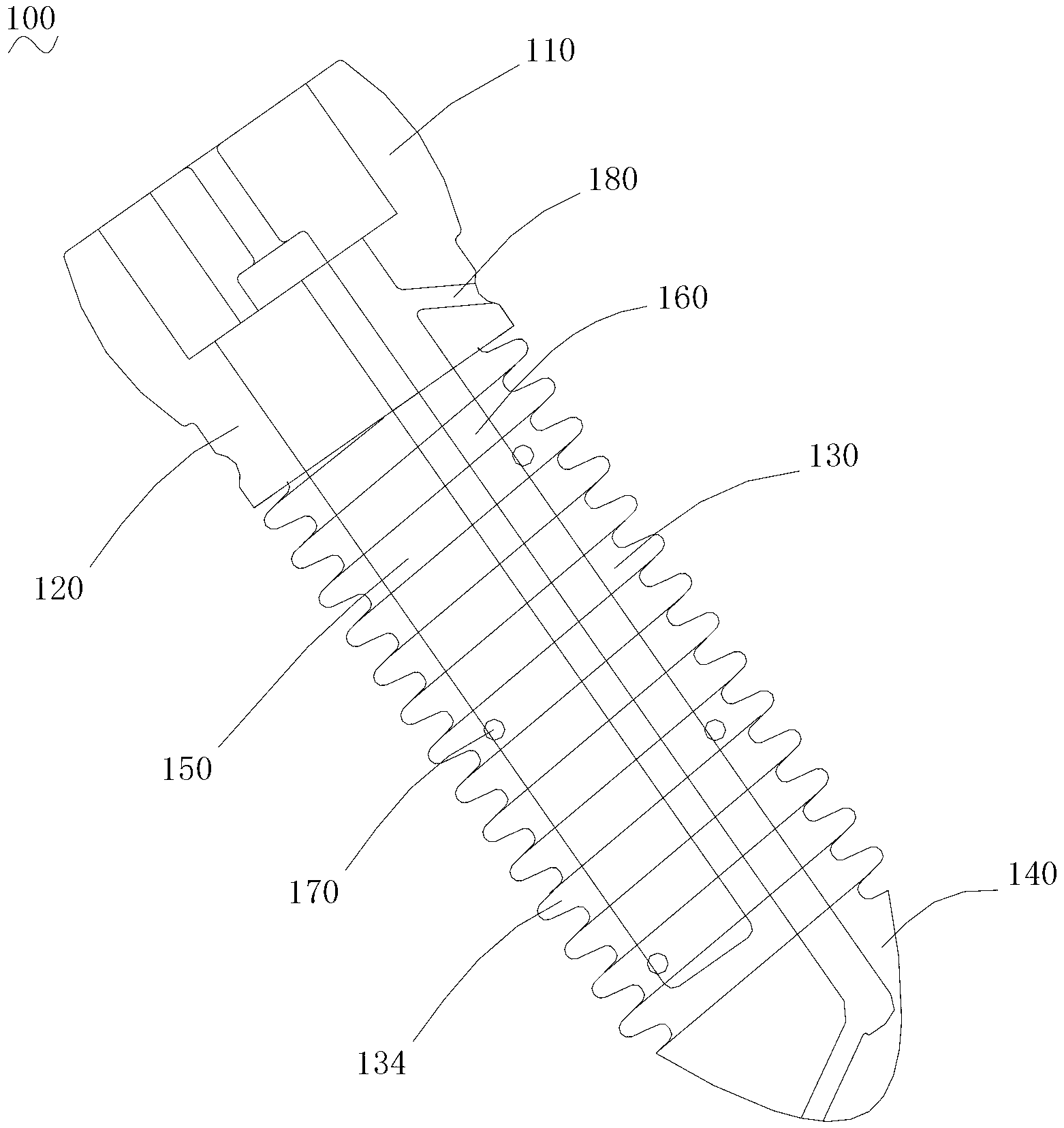

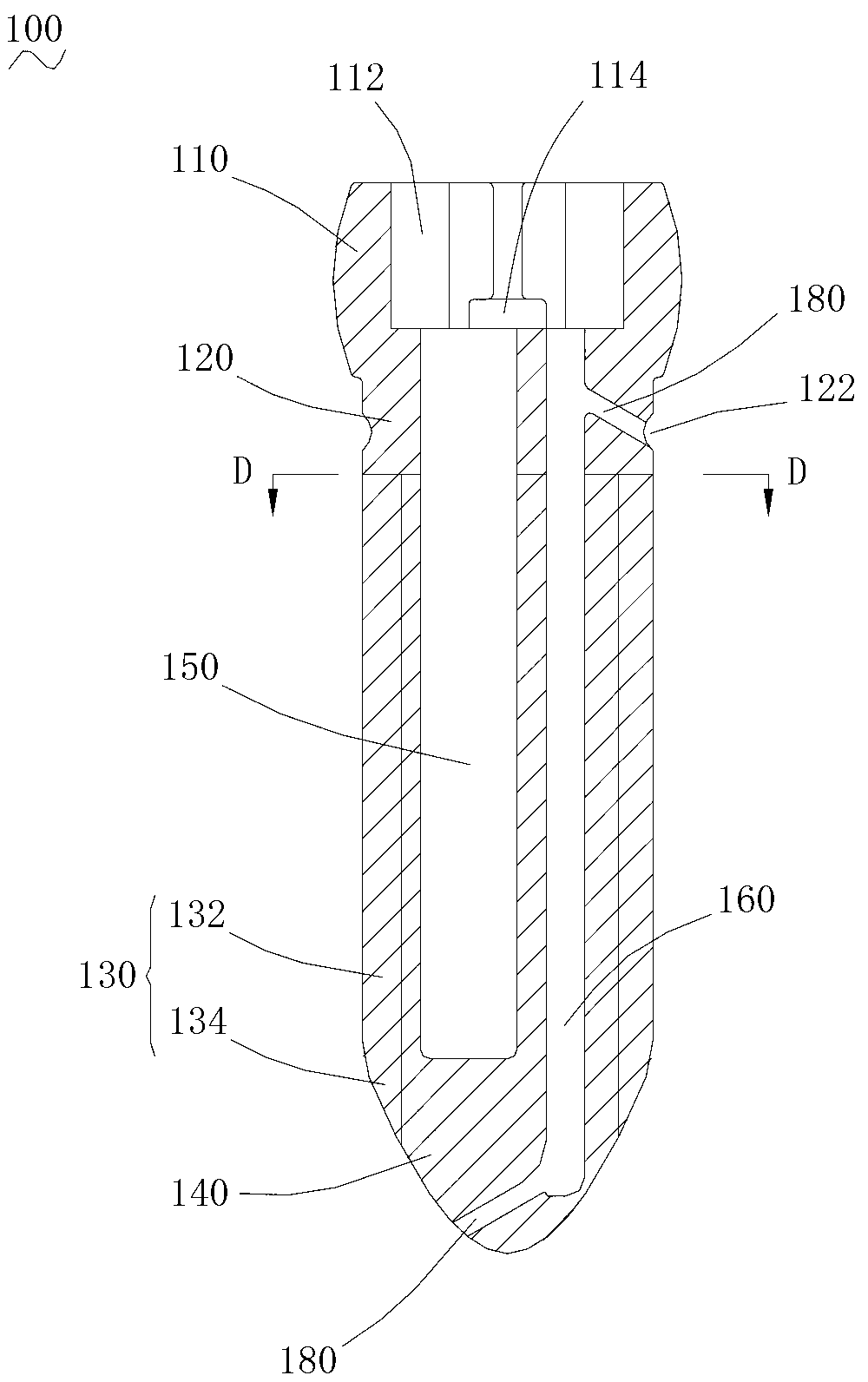

[0023] Please refer to Figure 1 to Figure 6 , a bone screw 100 for fixing osteoporotic bone in one embodiment includes a bone screw body, and the bone screw body includes a head 110 , a neck 120 , a bolt body 130 and a tail 140 connected in sequence.

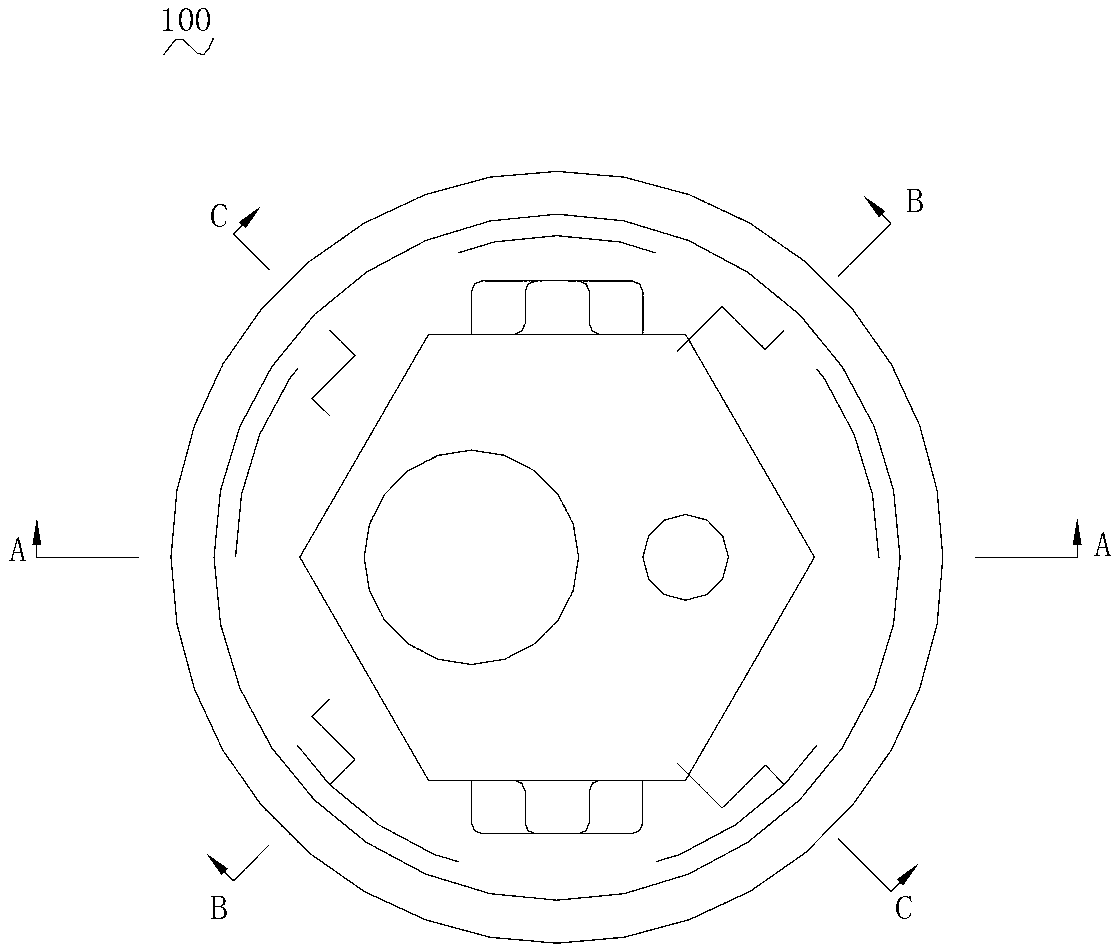

[0024] Please refer to Figure 1 to Figure 3 , the head 110 is provided with an axial regular hexagonal groove 112, which facilitates subsequent use of tools to remove the bone screw from the bone. The opposite side walls of the regular hexagonal groove 112 are respectively provided with an inverted T-shaped groove structure 114, and the opening of the inverted T-shaped groove structure 114 is located on the upper surface of the head 110, which is also to facilitate the removal of the screw. And design. The bottom of the regular hexagonal groove 112 is respectively provided with a parallel first channel 150 and a second channel 160 along the axial direction, wherein the first channel 150 runs through the neck 120 and extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com