Compound fertilizer slurry centrifugal filter using melt method

A centrifugal filter and compound fertilizer technology, applied in filtration separation, filtration loop, separation method, etc., can solve the problems of high labor intensity, difficult cleaning and maintenance, low degree of automation, etc., and achieve easy cleaning and reduce labor intensity. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

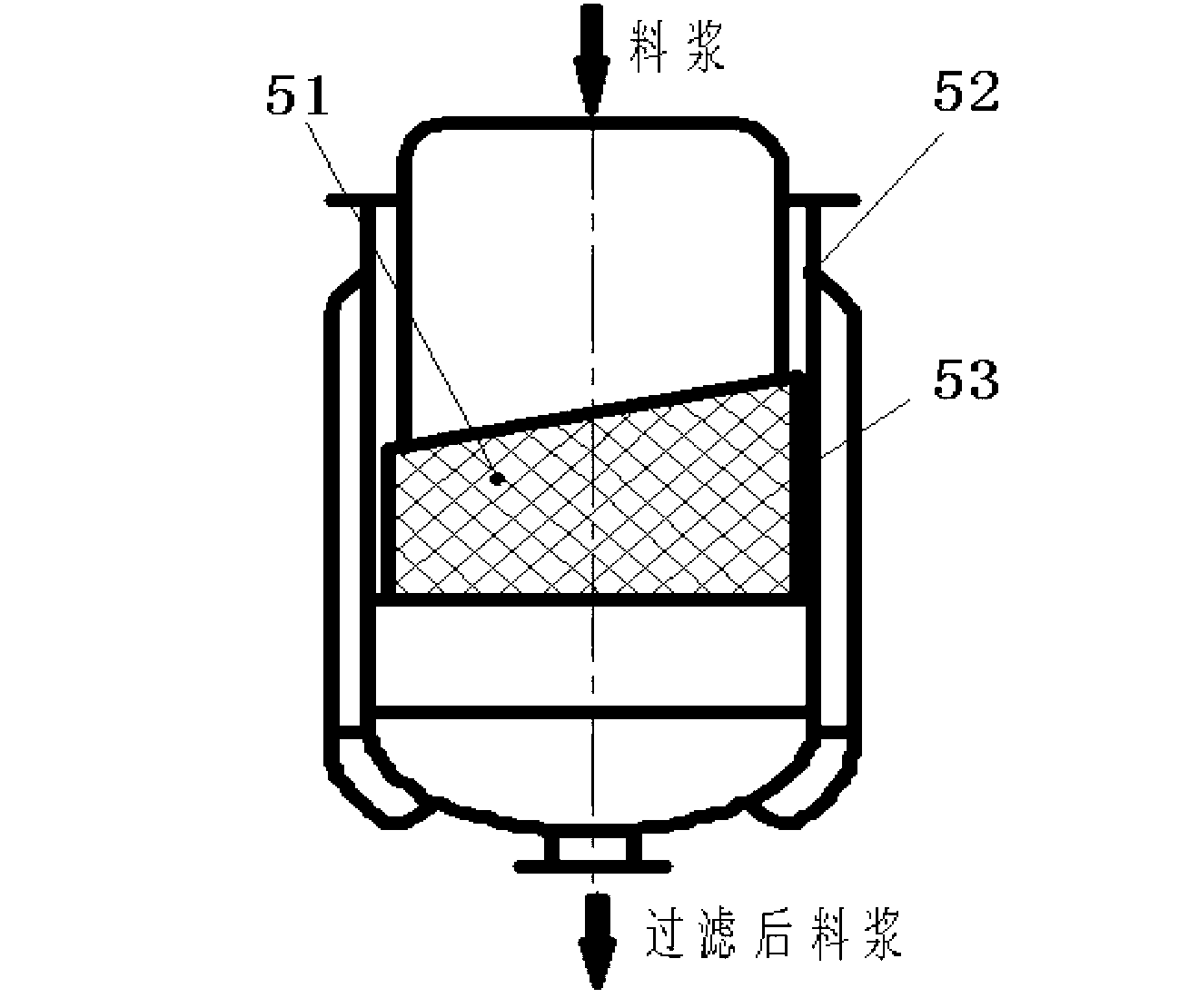

[0031] like figure 1 As shown, the structure of the fixed filter in the prior art is that a filter frame 51 is directly arranged in the inner cavity of the cylinder body A52, and a thermal insulation jacket A53 is arranged on the outer surface of the cylinder body A52, and the slurry enters the inner cavity of the cylinder body A52 Filtering is implemented through the filter box 51.

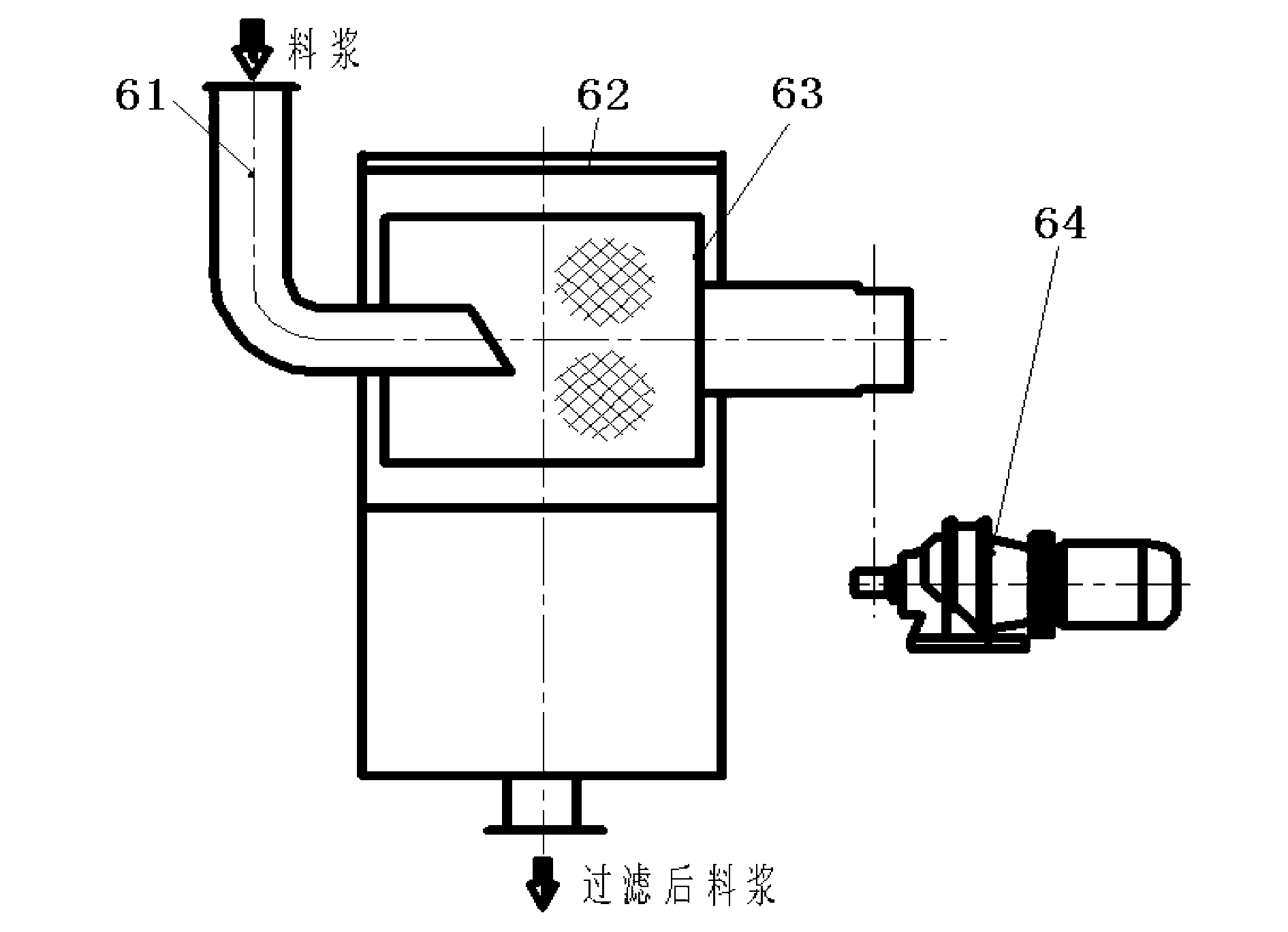

[0032] like figure 2 As shown, the structure of the rotary filter in the prior art is that an annular filter screen 63 is arranged horizontally in the cylinder body B62, the filter screen 63 is connected with the transmission system 64 to realize rotation, and the slurry enters from the feed pipe A61 In the cylinder B62, it is filtered through the rotating filter 63 and discharged downward.

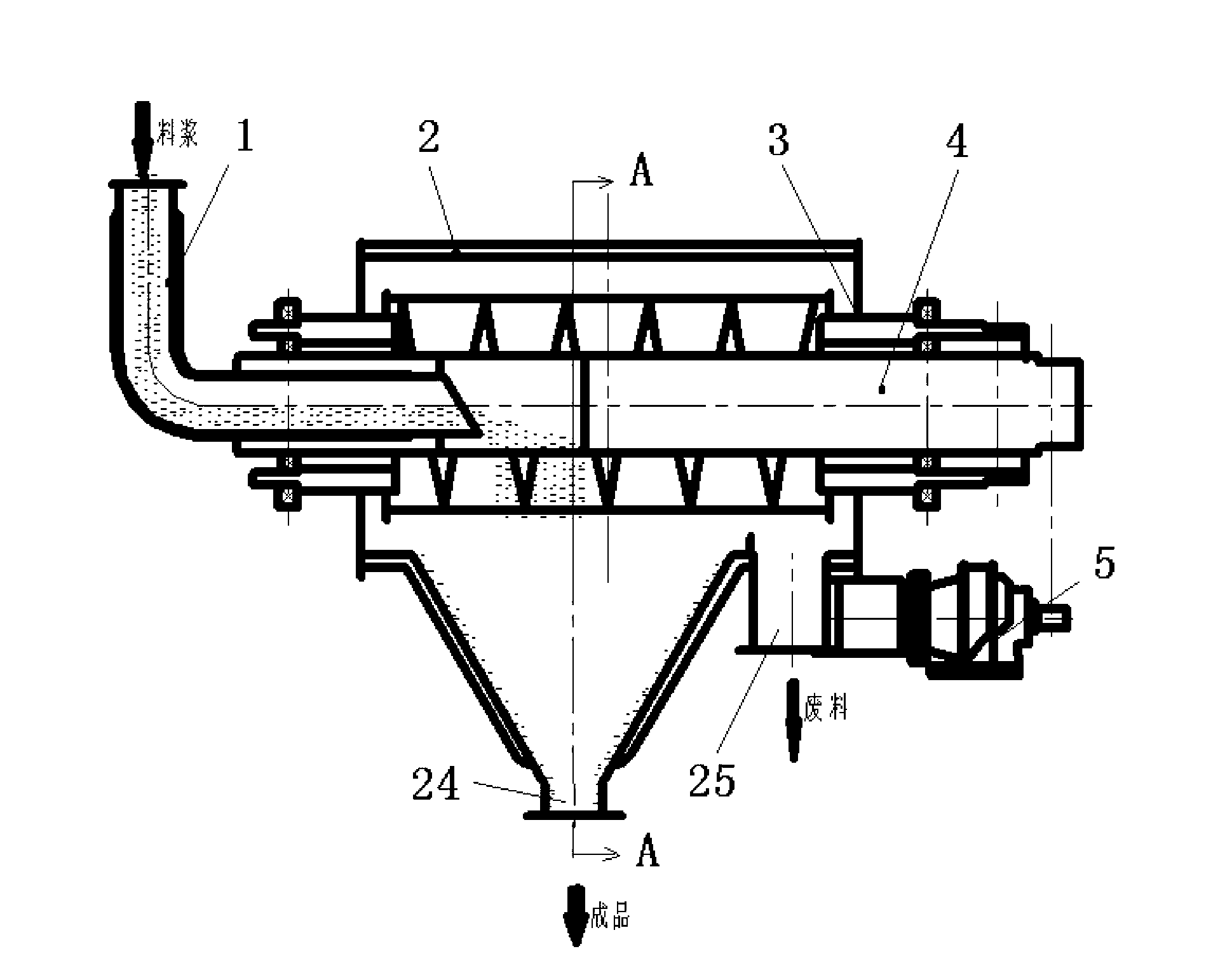

[0033] The structure of filter of the present invention is, with reference to image 3 , Figure 4 , Figure 5 , mainly including a cylinder assembly 2, a filter mechanism 3, a slag cleaning device 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com