Agitation reactor

A reactor and stirring paddle technology, which is applied in the field of stirring reactors, can solve the problems such as the inability to achieve uniform mixing and reaction, and achieve the effects of uniform solid-liquid two-phase mixing and enhanced turbulent flow form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

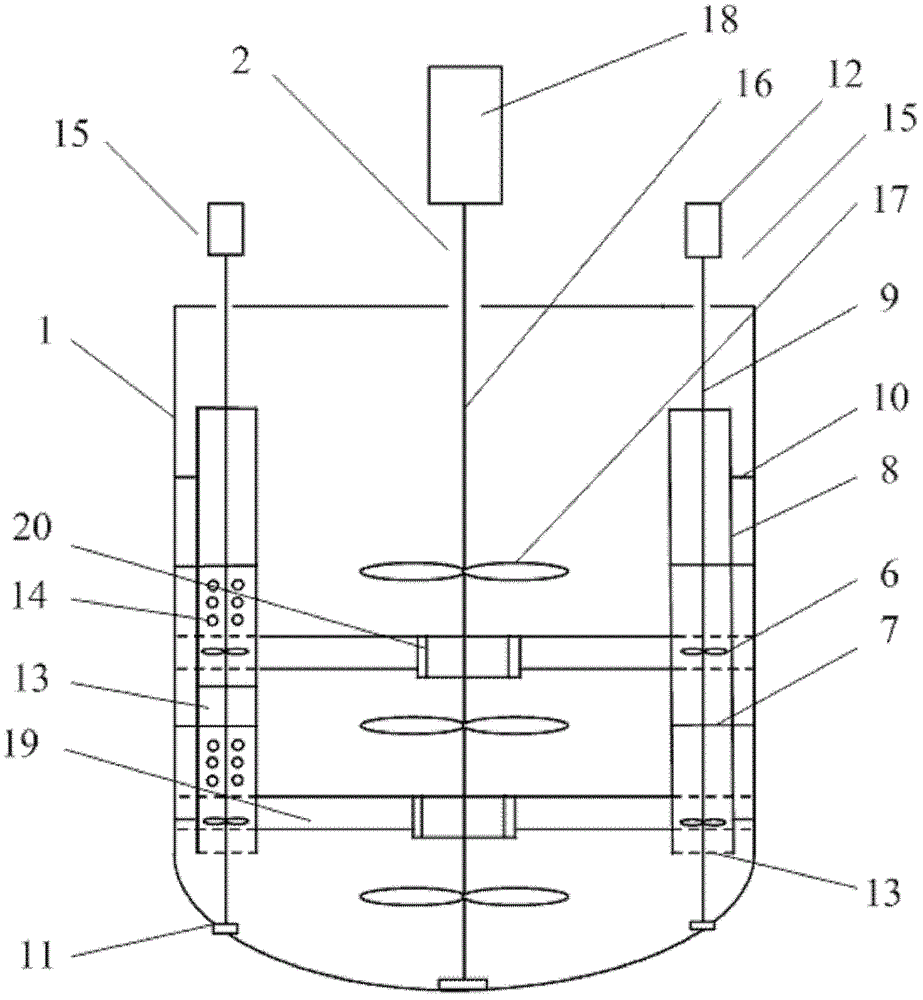

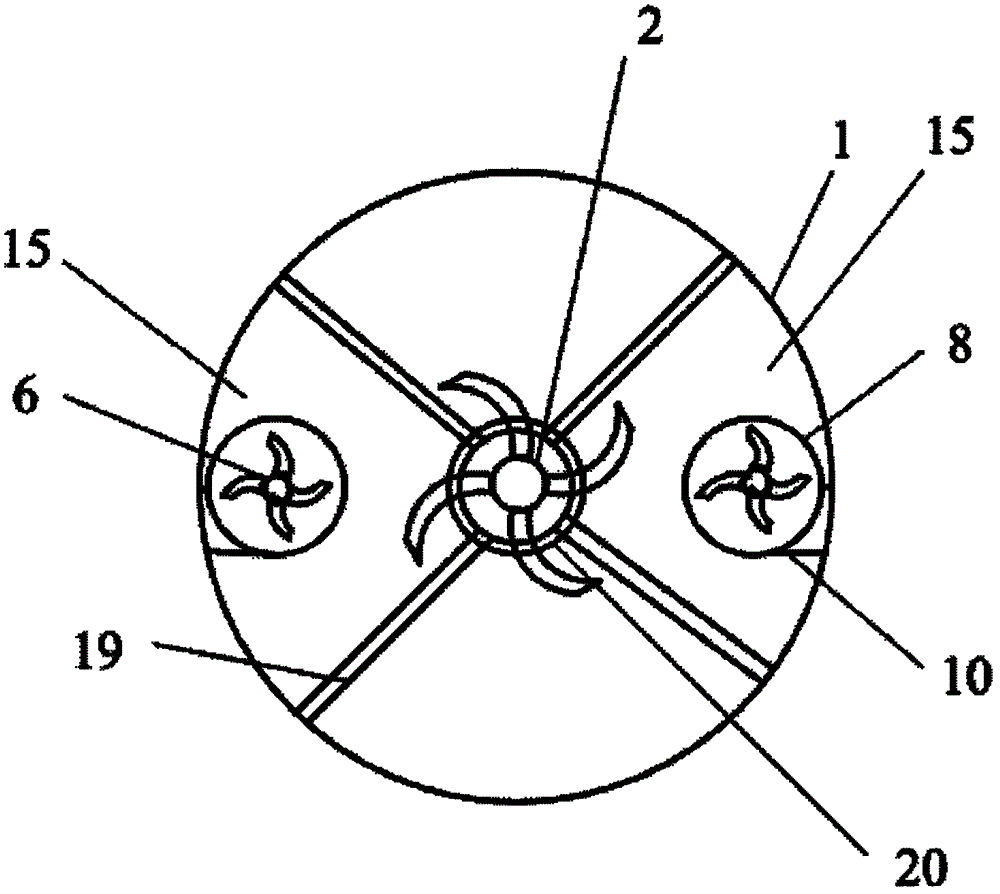

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0035] In the present invention, unless stated to the contrary, the used orientation words such as "upper, lower, frontal, rearward" are generally defined in the assembled state of the leading cutting device provided by the present invention. The front side of the shell refers to the side facing the material flow direction during the rotation of the material in the container of the stirred reactor, and the rear side of the shell refers to the side opposite to the front side of the shell.

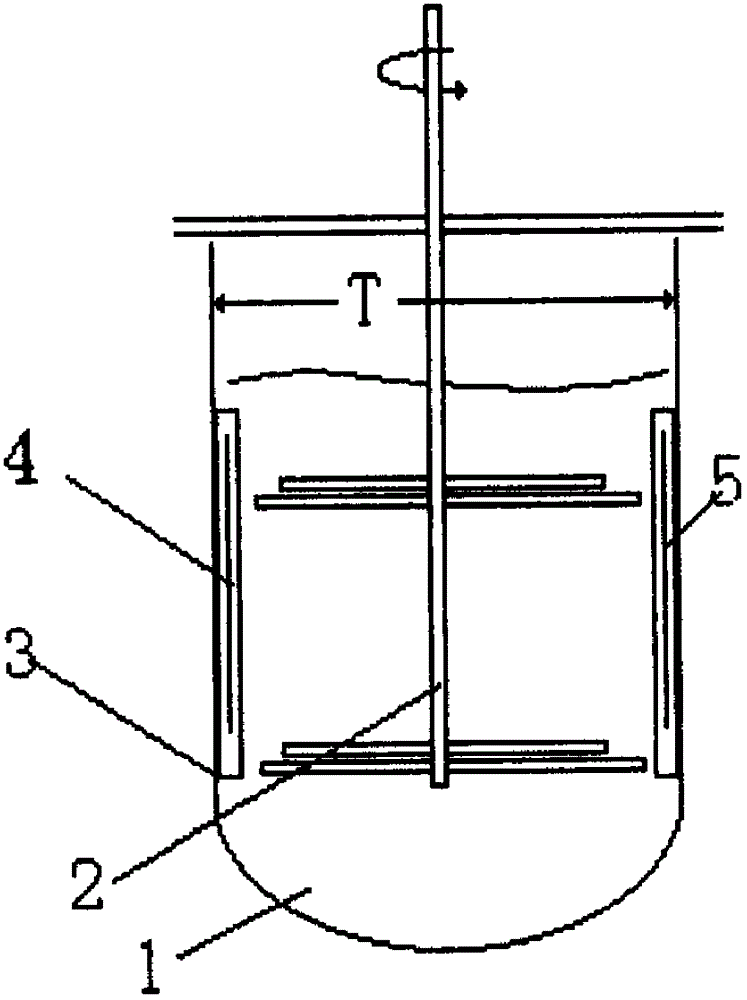

[0036] Such as Figure 2 to Figure 4 As shown, the present invention provides a kind of stirred reactor, and this stirred reactor comprises container 1 and the stirring devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com