Powder metering control system, method and device

A technology for controlling system and powder, applied in the field of systems and devices, powder metering control method, can solve problems such as deviation, and achieve the effect of reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

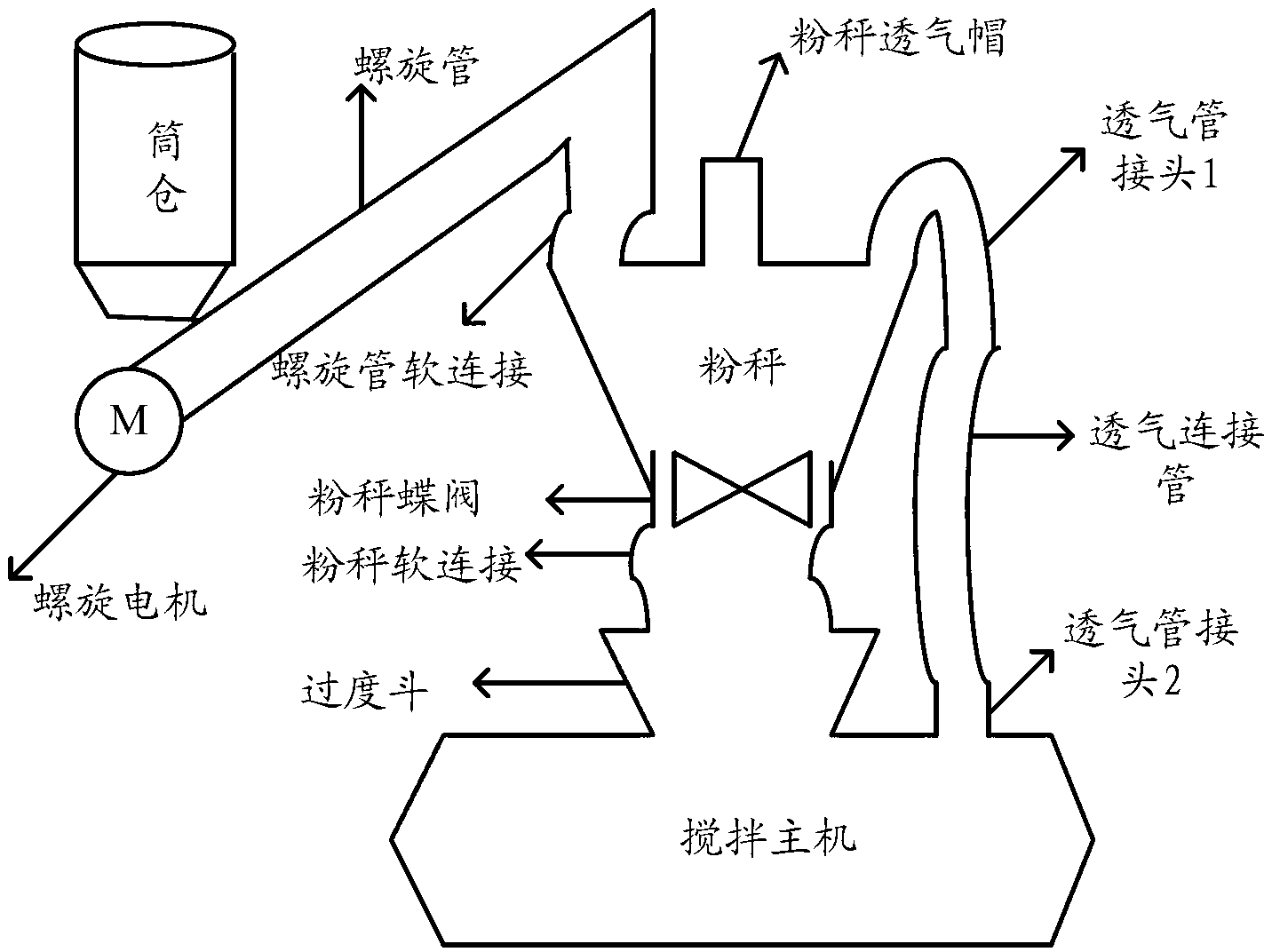

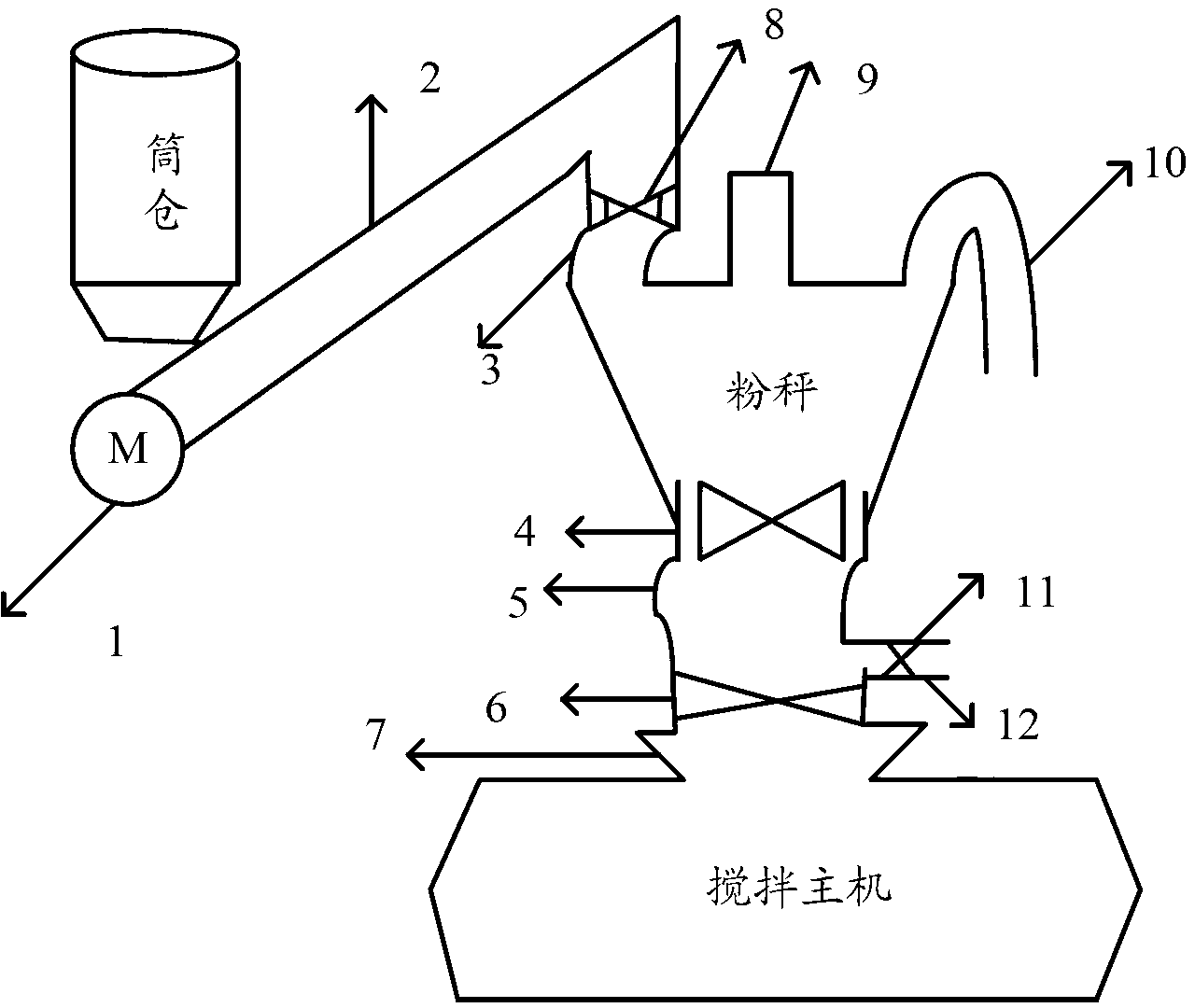

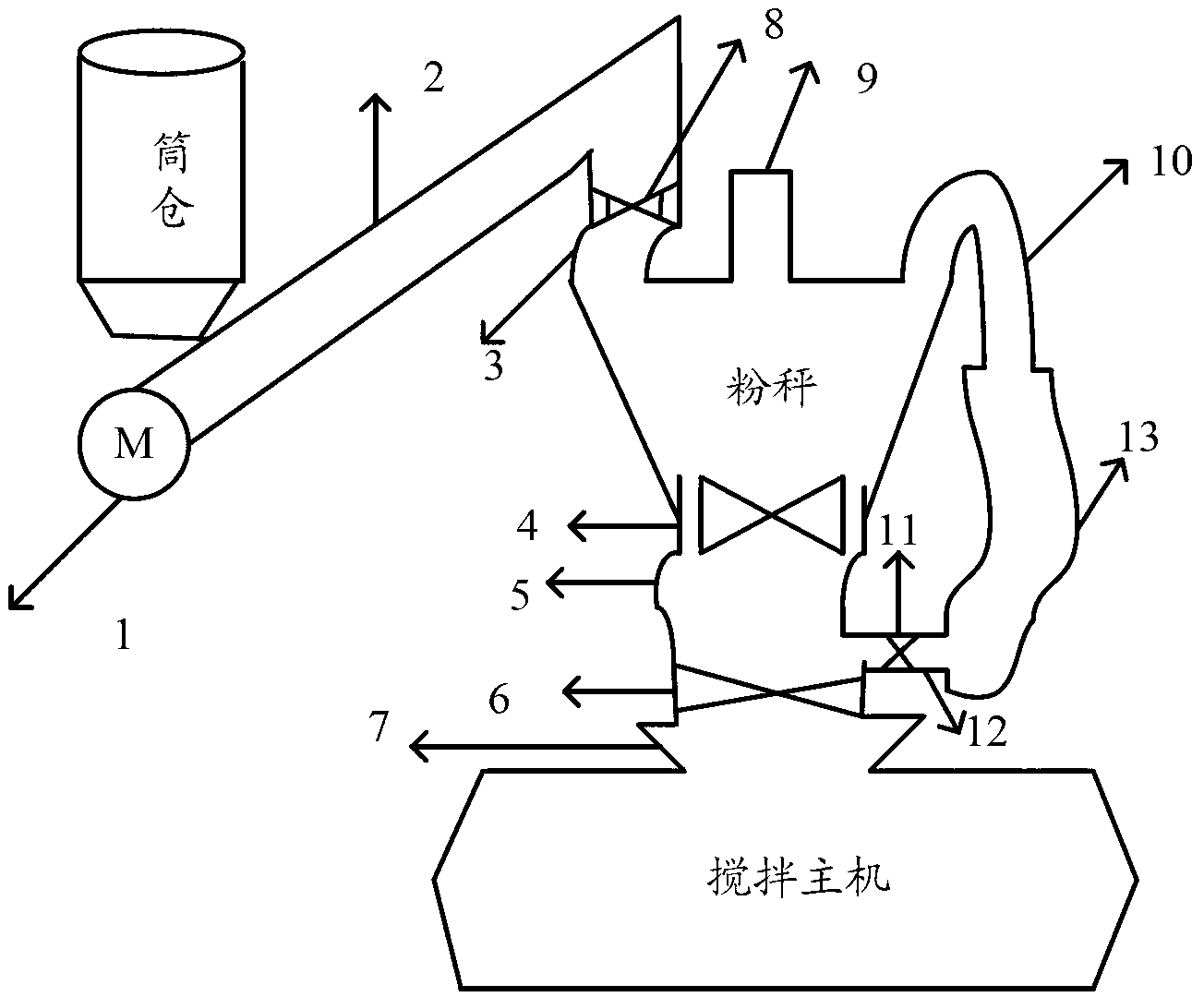

[0023] At present, the structure of the powder metering control system including powder scales and other stirring mechanical products in the prior art is as follows: figure 1 shown. In addition to the powder scale, the system also includes the mixing main engine, the transition bucket, the soft connection of the powder scale, the butterfly valve of the powder scale, the vent pipe joint 1, the vent pipe joint 2, the vent connection pipe, the spiral motor, the spiral pipe, the spiral pipe soft connection and Powder scale breathable cap and other mechanical structures. Among them, the soft connection of the powder scale and the transition bucket are sequentially connected between the powder scale and the mixing main engine; the powder scale butterfly valve is also installed on the upper part of the powder scale soft connection and the bottom of the powder scale. In addition, the vent pipe joint 1 on the powder scale is connected to the vent pipe joint 2 on the mixing main machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com