Yarn winding machine and yarn winding unit

A technology of a winding machine and yarn, applied in the structural field of the yarn splicing part, can solve the problems of inability to guarantee, insufficient inspection accuracy of the yarn splicing part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

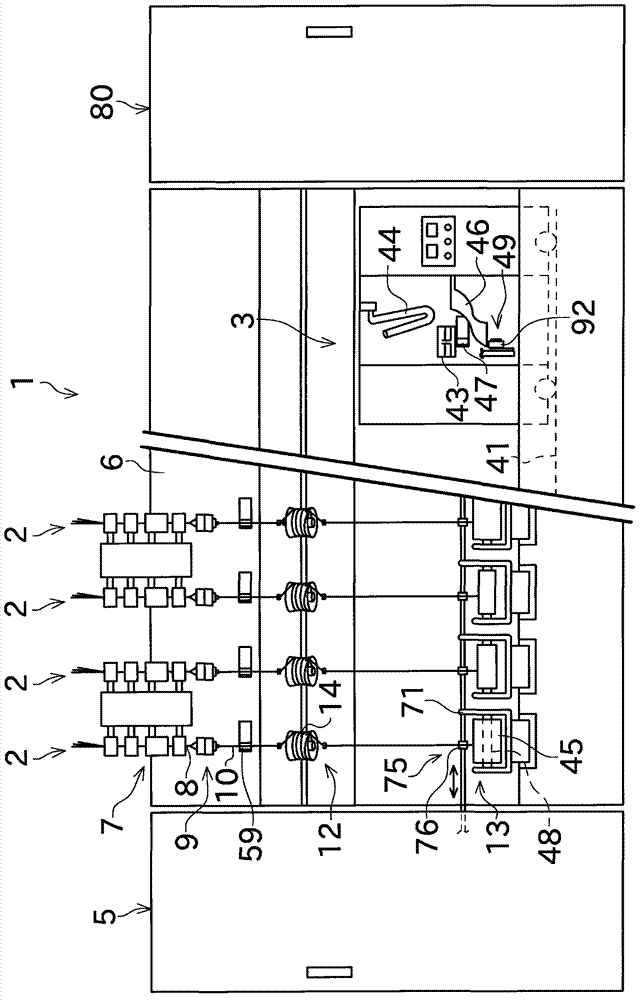

[0037] Next, a spinning machine as a yarn winding machine according to an embodiment of the present invention will be described with reference to the drawings. figure 1 The illustrated spinning machine (spinning machine) 1 has: a plurality of spinning units (yarn winding units) 2 arranged in parallel; a yarn splicing trolley 3; a fan box 80;

[0038] A negative pressure source and the like for supplying negative pressure to each spinning unit 2 are arranged in the fan box 80 . A drive source common to the spinning units 2 is arranged in the prime mover case 5 .

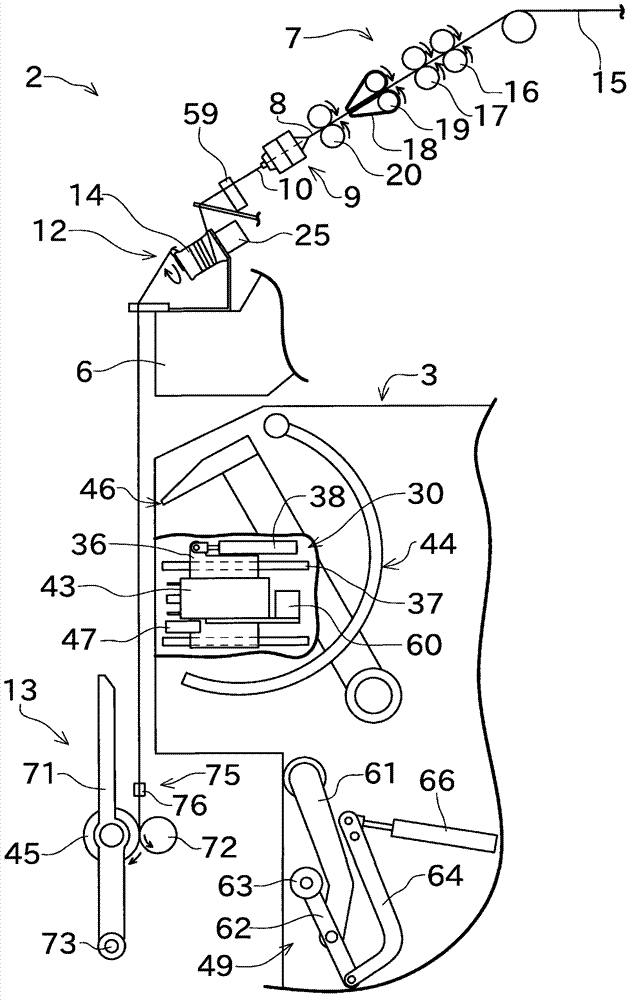

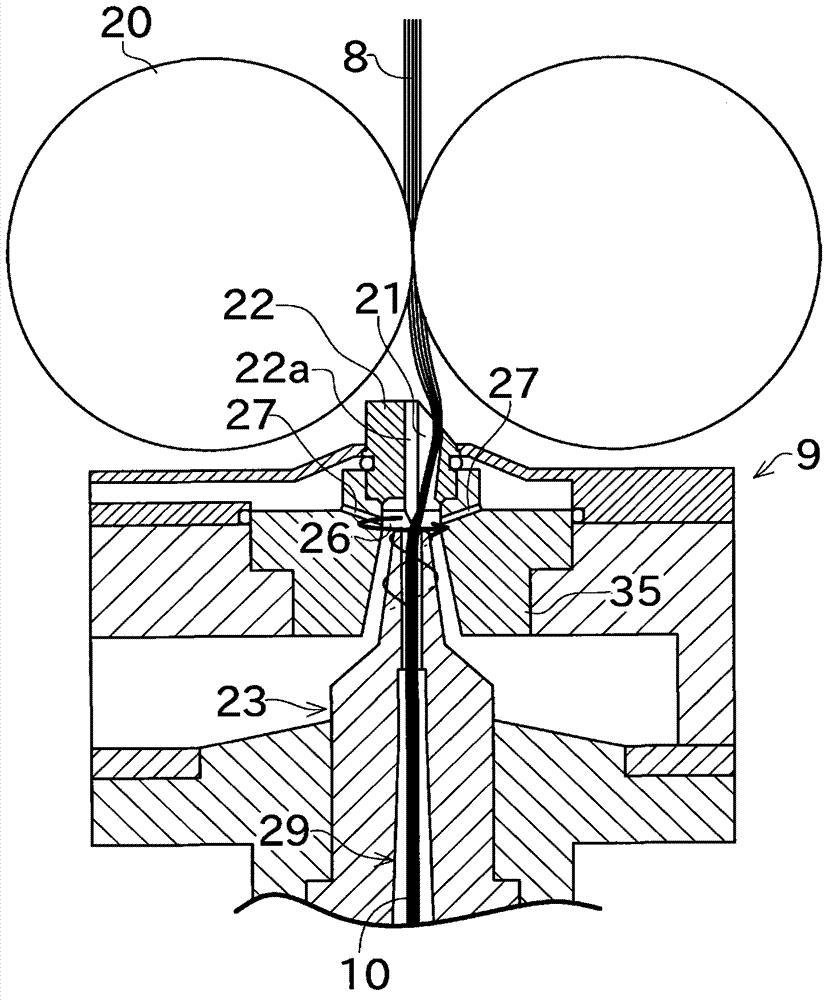

[0039] Such as figure 2 As shown, each spinning unit 2 has a draft device 7, a spinning device (yarn feeding section) 9, a yarn accumulating device 12, and a winding device (winding section) 13 arranged sequentially from upstream to downstream. Each spinning unit 2 spins the fiber bundle 8 sent from the drafting device 7 in the spinning device 9 to generate a spun yarn 10, and the spun yarn 10 is wound on a bobbin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com