Artificial inner gas stripping anaerobic reactor

A reactor and air stripping technology, applied in the field of sewage treatment reactors, can solve the problems of difficult classification, high energy consumption, expensive equipment, etc., and achieve the effects of suitable control, stable operation, and low energy consumption of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

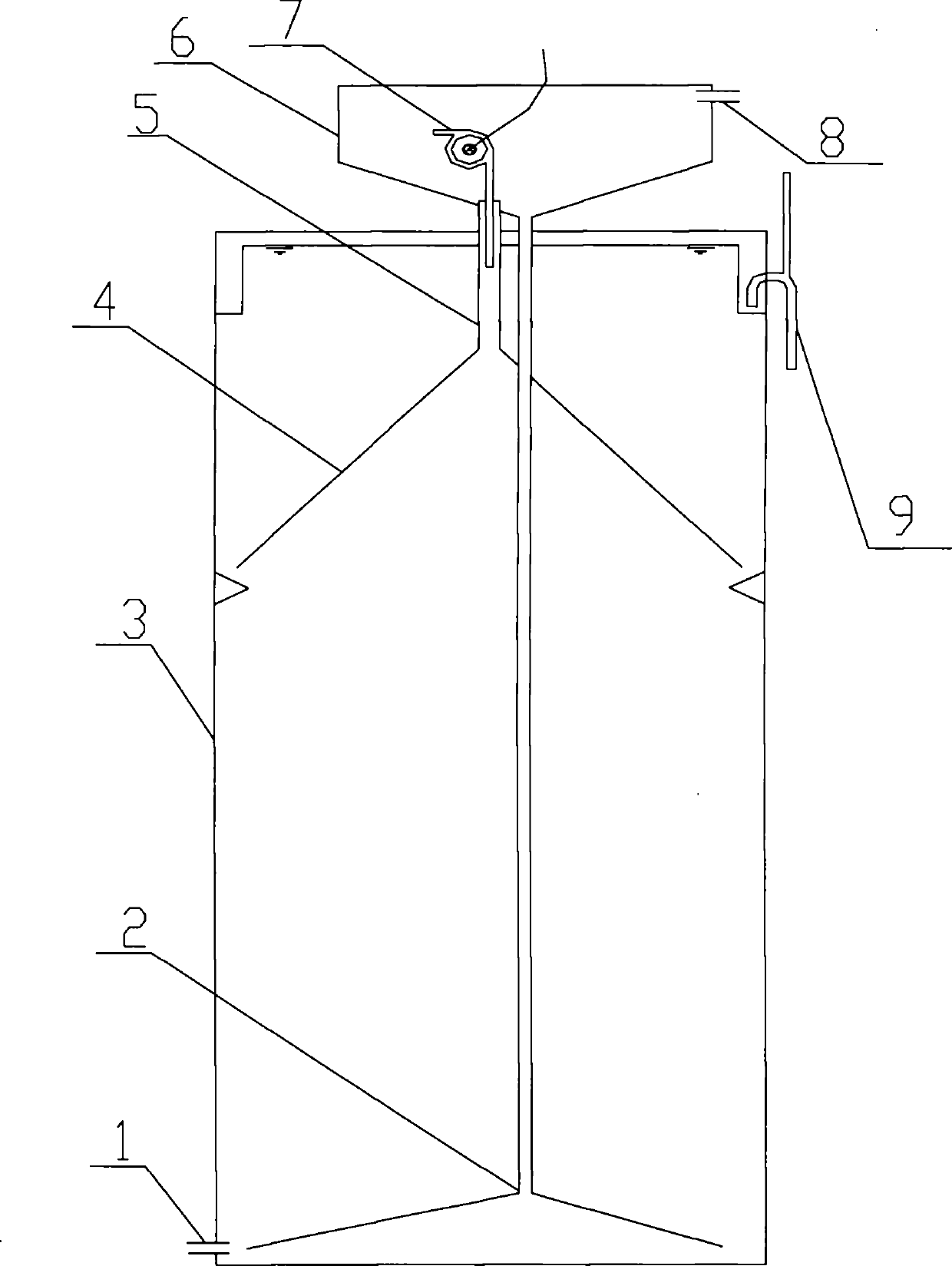

Embodiment 1

[0018] like figure 1 The artificial internal air lift anaerobic reactor shown includes: water inlet 1, return pipe 2, reactor shell 3, gas collection and separation cover 4, air lift pipe 5, gas-liquid separator 6, air lift fan 7, Biogas outlet 8, water outlet 9.

[0019] The working principle of the present embodiment 1 is briefly introduced as follows:

[0020] When the sewage enters the reactor shell 3 from the water inlet 1, the pollutants are removed through the action of microorganisms in the reactor, and biogas is generated at the same time. The generated biogas rises to the gas collection and separation hood 4 , and under the action of the gas collection and separation hood 4 , the sludge flows back to the reaction zone, the sewage flows to the water outlet 9 , and the biogas enters the stripping pipe 5 . The function of the gas collection and separation cover 4 here is the same as that of the three-phase separator in the UASB. The biogas entering the stripping pipe...

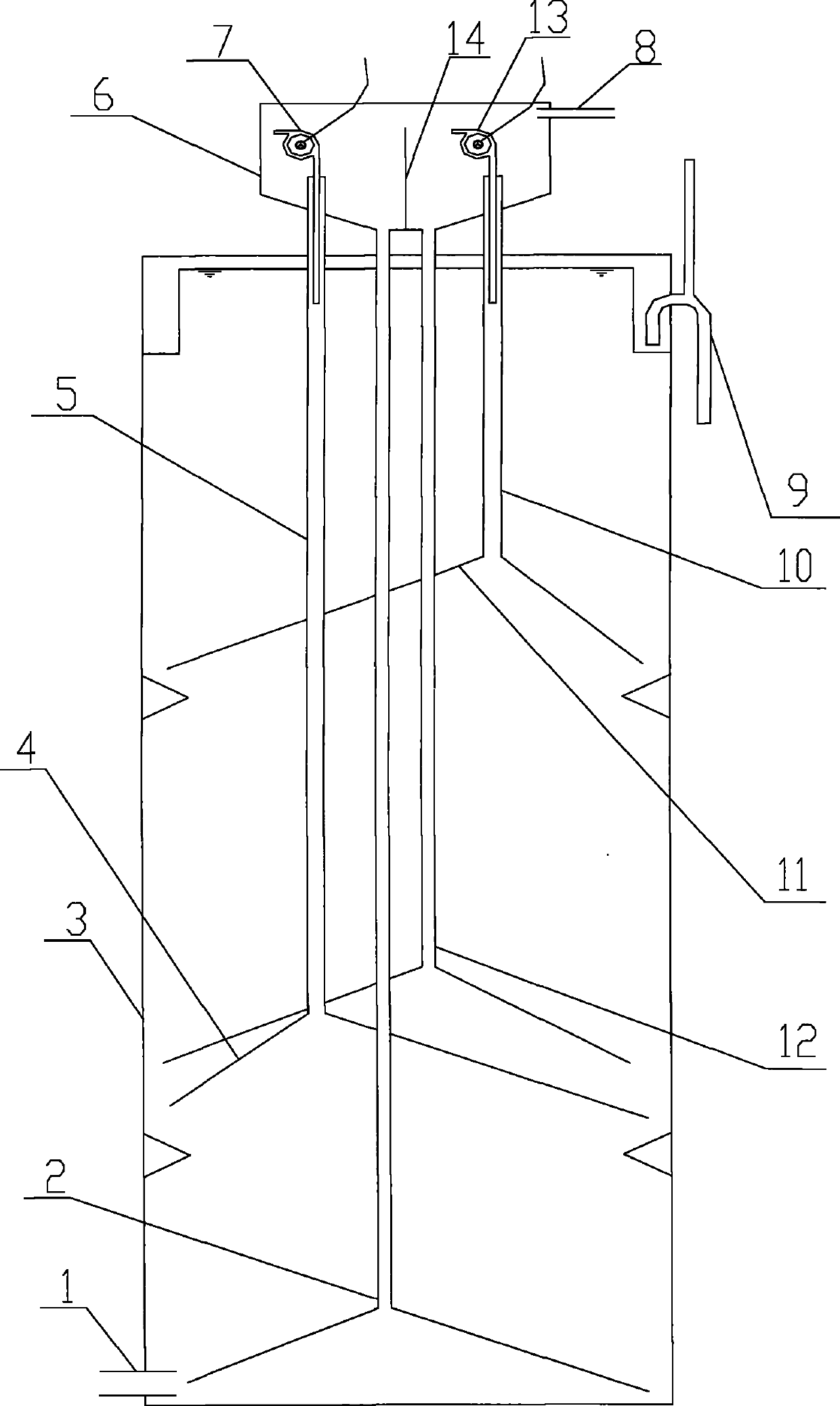

Embodiment 2

[0022] like figure 2 The auxiliary internal gas-lifting anaerobic reactor shown, the difference between the second embodiment and the first embodiment is that the secondary gas-lifting pipe 10, the secondary gas-collecting separation cover 11, the secondary return pipe 12, the secondary The air lift fan 13 and the baffle plate 14, through the addition of these components, form a vertical series reactor, increase the reaction area, and thus make the adaptability of the reactor wider.

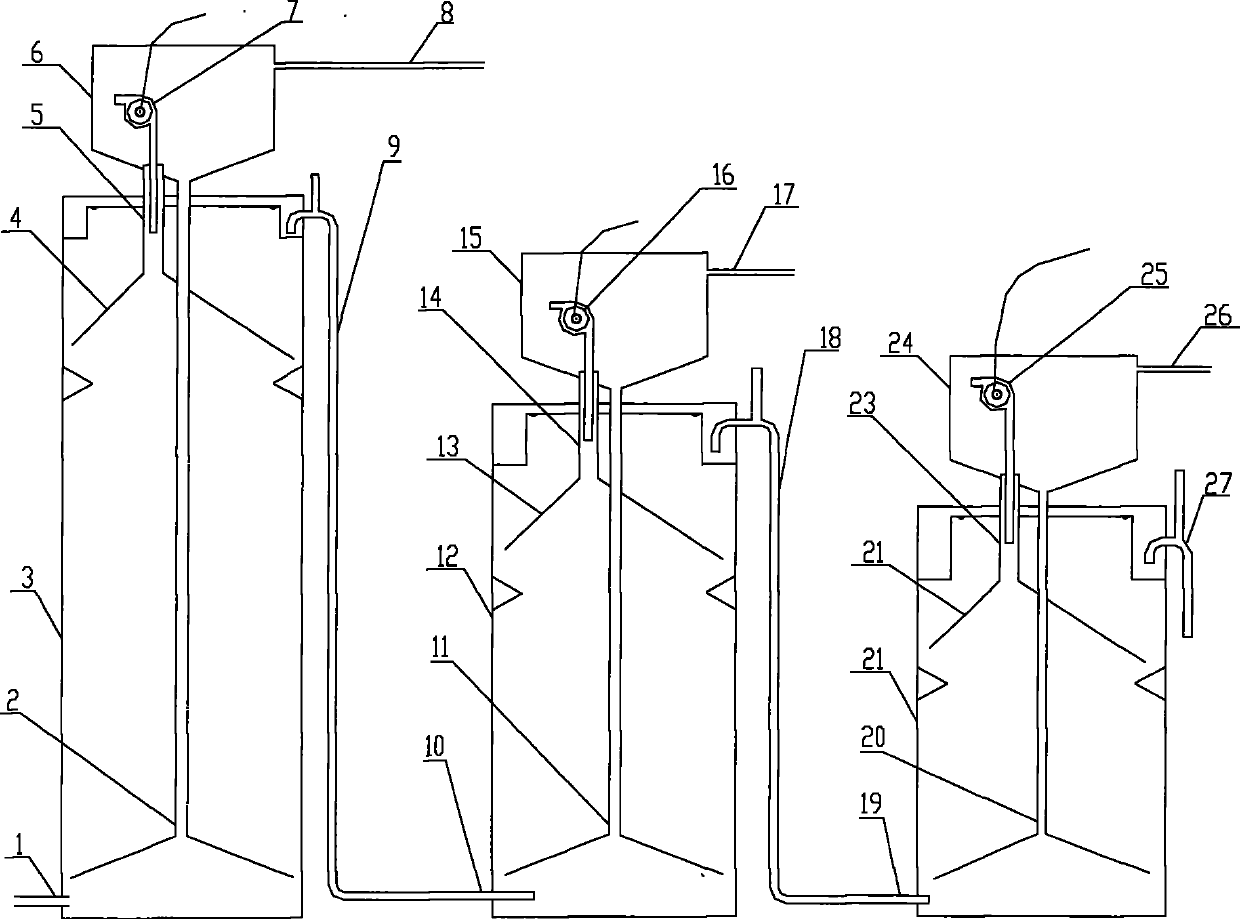

Embodiment 3

[0024] like image 3 The auxiliary internal air-lift anaerobic reactor shown includes: water inlet 1, primary return pipe 2, primary reactor shell 3, primary gas-collecting and separating cover 4, primary air-lifting pipe 5, primary gas Liquid separator 6, primary gas lift fan 7, primary biogas outlet 8, primary water outlet 9, secondary water inlet 10, secondary return pipe 11, secondary reactor shell 12, secondary gas collection and separation cover 13. Secondary gas lift pipe 14, secondary gas-liquid separator 15, secondary gas lift fan 16, secondary biogas outlet 17, secondary water outlet 18, tertiary water inlet 19, tertiary return pipe 20, tertiary Reactor shell 21 , secondary gas collection and separation cover 22 , tertiary gas lift pipe 23 , tertiary gas-liquid separator 24 , tertiary gas lift fan 25 , tertiary biogas outlet 26 , and water outlet 27 . The primary water outlet 9 is connected to the secondary water inlet 10, and the secondary water outlet 18 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com