Novel air yarn equipment

A technology of filling core yarn and equipment, which is applied in yarn, textile and papermaking, etc., which can solve the problems of high production cost, high defective rate of a single incoming thread, and high price, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

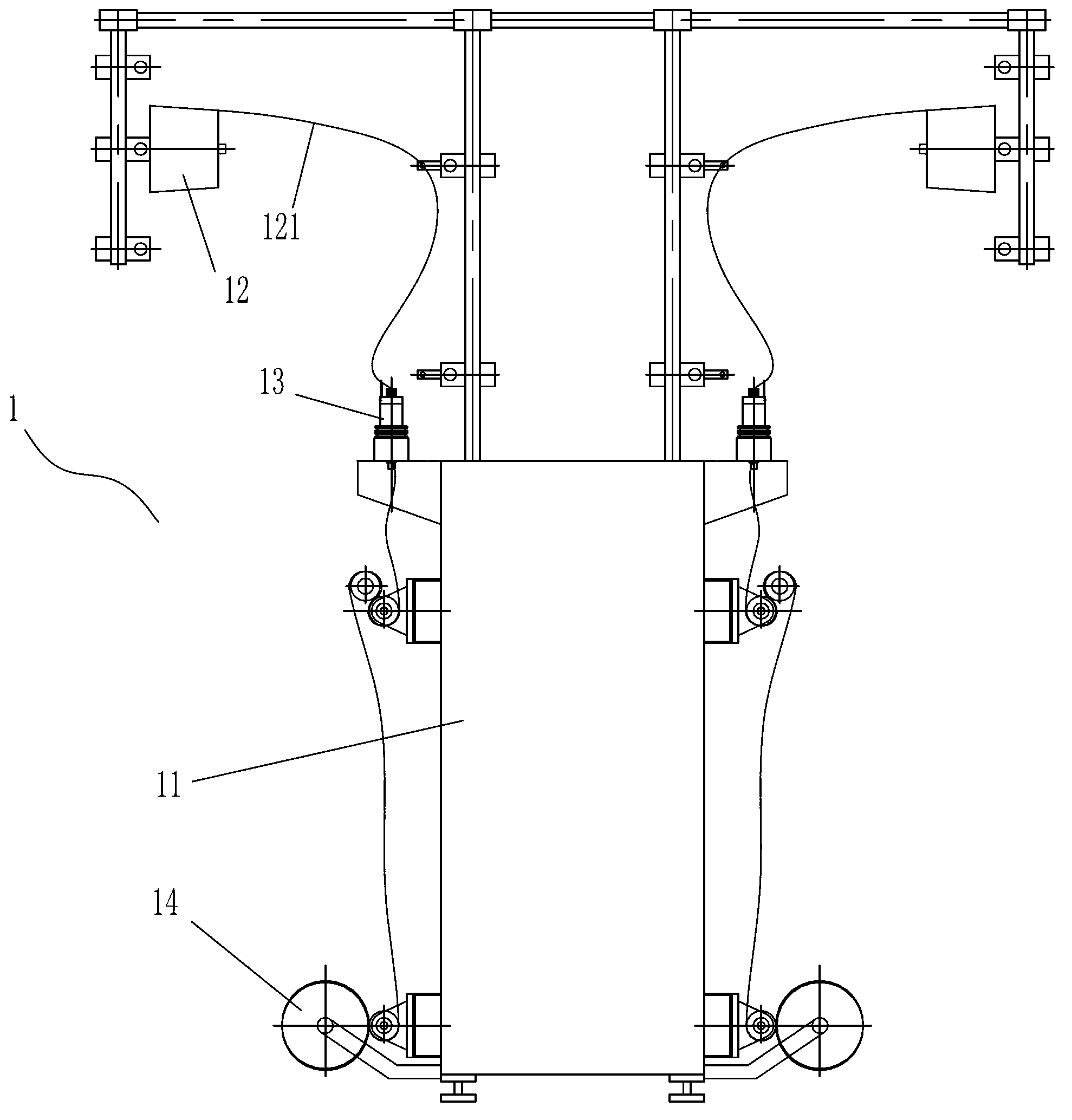

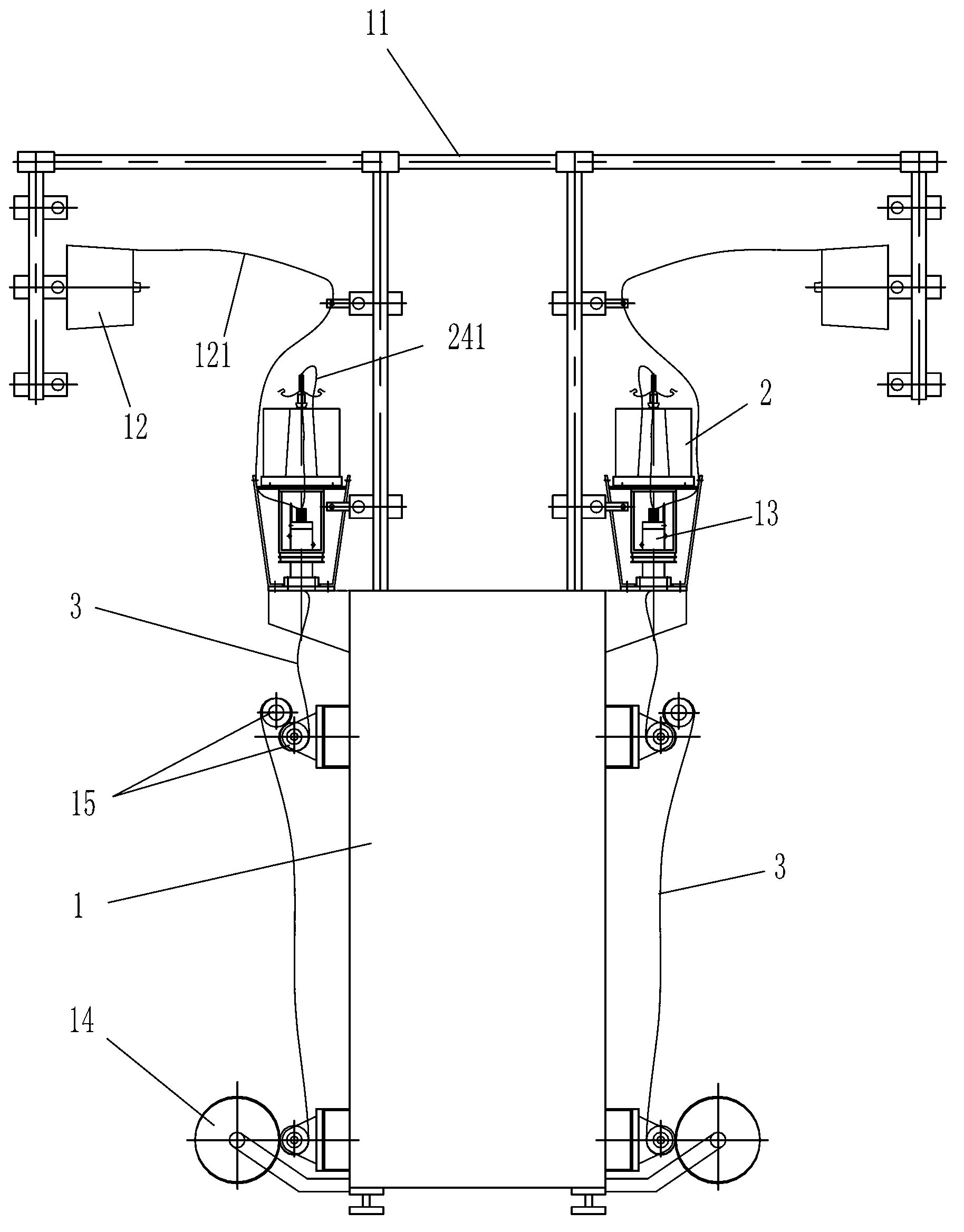

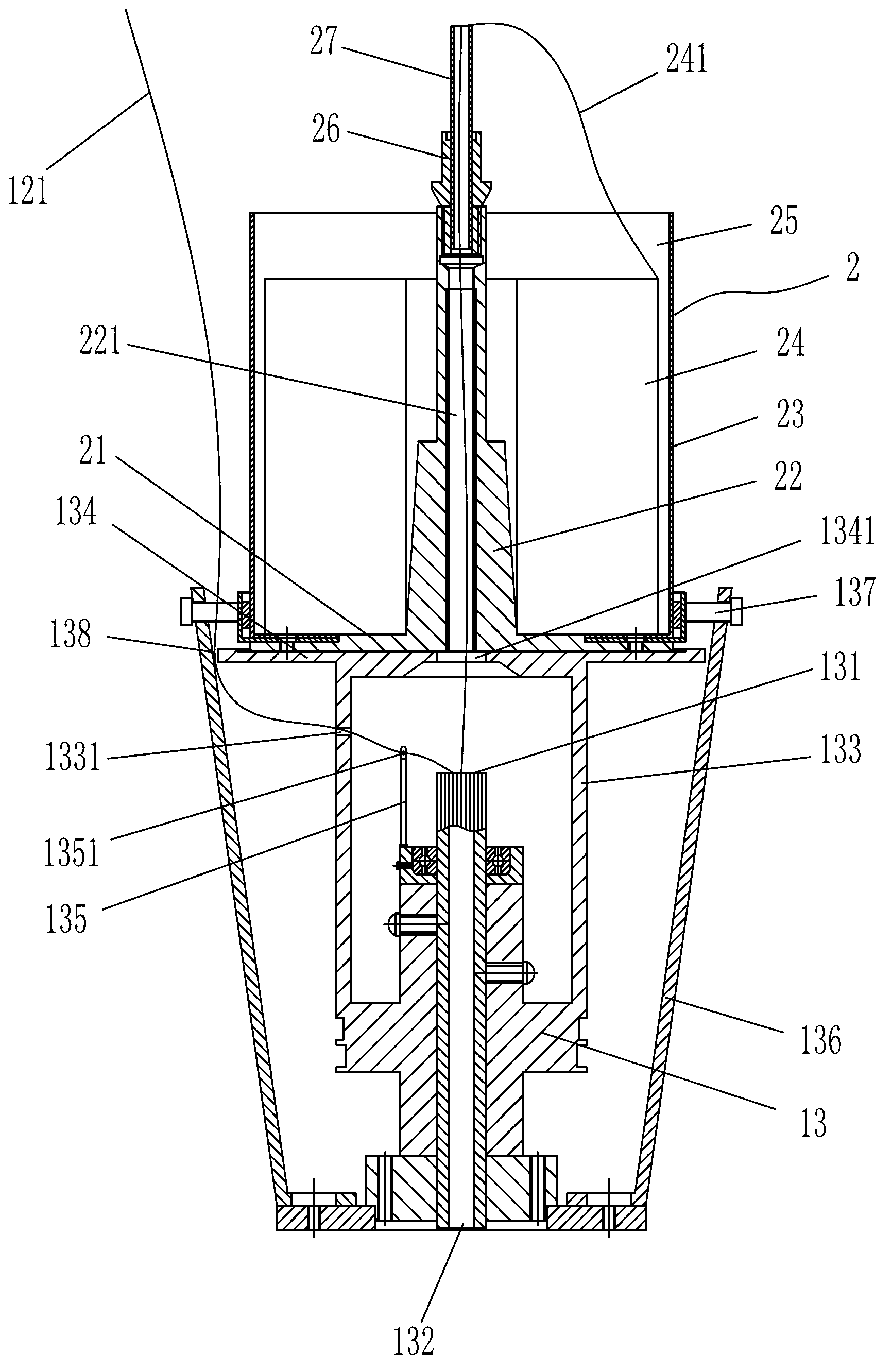

[0018] Example: such as figure 2 and image 3 As shown, a new type of core yarn equipment includes a needle cylinder machine 1. The needle cylinder machine 1 includes a frame 11, a yarn inlet disk 12 arranged on the frame 11, a needle cylinder 13 and a yarn output disk 14. A core filling device 2 is fixed above the cylinder 13, and the core filling device 2 includes a fixing seat 21. The center of the fixing seat 21 has a longitudinally extending yarn guide column 22, and the outer periphery of the fixing seat 21 is provided with a first sleeve 23. A yarn storage cavity 25 for accommodating the core yarn reel 24 is formed between the first sleeve 23 and the yarn guide column 22, and the yarn guide column 22 has a yarn guide hole in communication with the yarn inlet 131 of the needle cylinder 13 221, the upper end of the yarn guide hole 221 of the yarn guide post 22 is plugged and fixed with the yarn guide tube 27 through the connector 26, and when weaving, the core thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com