Construction method for underwater baring platform steel cover box on storm surge river mouth

A steel casing and casing technology, which is applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of numerous procedures and long installation period of casings, and achieve the effect of resisting the impact of surges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

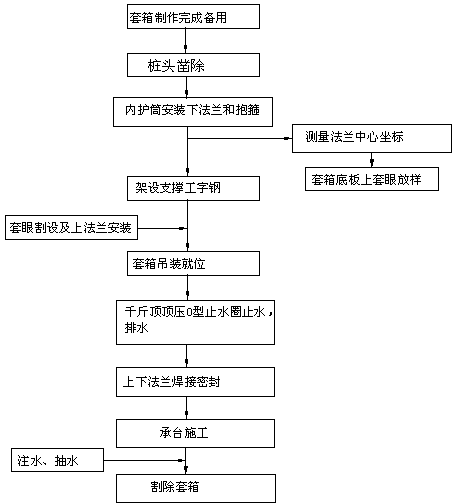

[0015] The present invention will be further described below in conjunction with the accompanying drawings:

[0016] refer to figure 1 As shown, in Example 1, a construction method of a steel box for the underwater cap of a strong tidal estuary, the steps are as follows: (1) the box is designed and manufactured for standby; (2) the pile head is removed: after the construction of the foundation grouting pile is completed, the outer casing is removed first. Pull out, use the outer casing to retain water, and carry out pile head chisel removal. According to the design drawings, the concrete of the cast-in-place pile needs to go deep into the bottom plate of the cap. In order to facilitate the welding of the upper and lower flanges in the next process, the pile head concrete needs to be chiseled into a "product" shape; (3) after the pile head is chiseled, use the outer casing to retain water Weld the lower flange and install the hoop on the outer wall of the inner casing. After t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap