Aluminum alloy floor and metal keel arrangement structure

A metal keel, aluminum alloy technology, applied in building structure, floor, building and other directions, can solve problems such as inconvenient installation, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

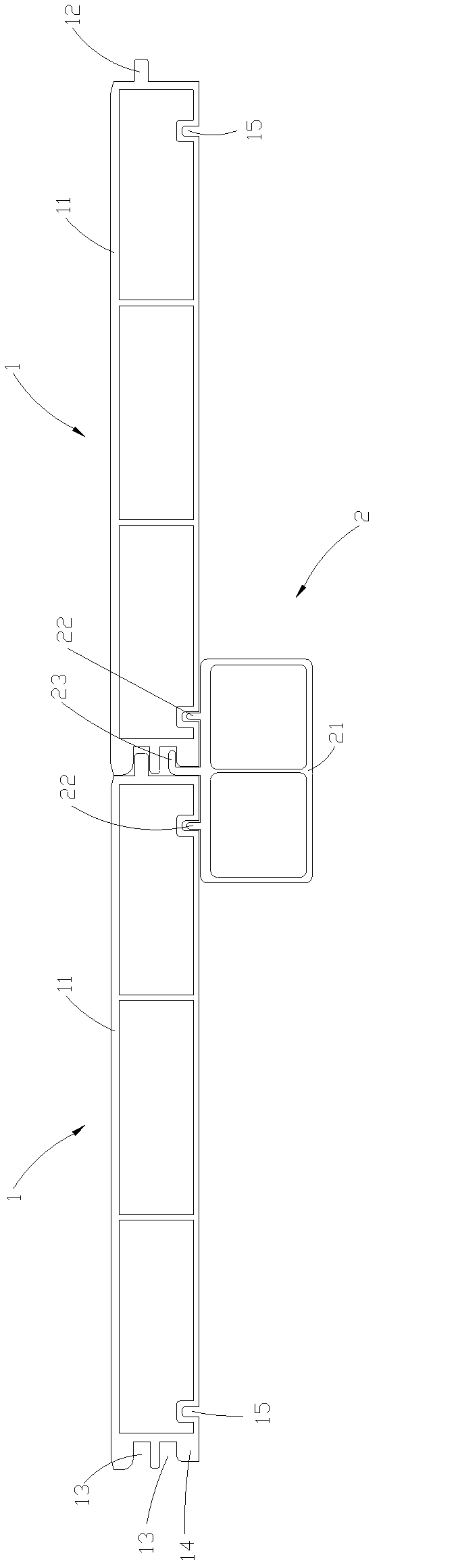

[0018] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 As shown, an arrangement structure of an aluminum alloy floor and metal keels includes an aluminum alloy floor 1 and a metal keel 2 laid on the bottom of the floor 1 for carrying the floor 1. The floor 1 includes a floor body 11, and one side of the floor body 11 has There are multiple tenons 12 extending longitudinally, and the other side of the floor body 11 has multiple tenon grooves 13 extending longitudinally. The multiple tenons 12 and the multiple tenon grooves 13 are arranged at intervals along the thickness direction of the floor 1. Each tenon 12 can be correspondingly inserted in a plurality of tenon grooves 13, and at this moment, tight splicing can be performed between two floorboards 1 . Among the plurality of tongue grooves 13, a protruding connecting portion 14 is formed between the tongue groove 13 closest to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com