Super-heavy-load and anti-static epoxy self-leveling floor and construction method thereof

An anti-static ring and construction method technology, applied in the field of ground construction, can solve problems such as inability to meet industrial needs, inability to meet anti-static, uneven ground, etc., and achieve improved service life, good mechanical strength, and long-lasting static conduction performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

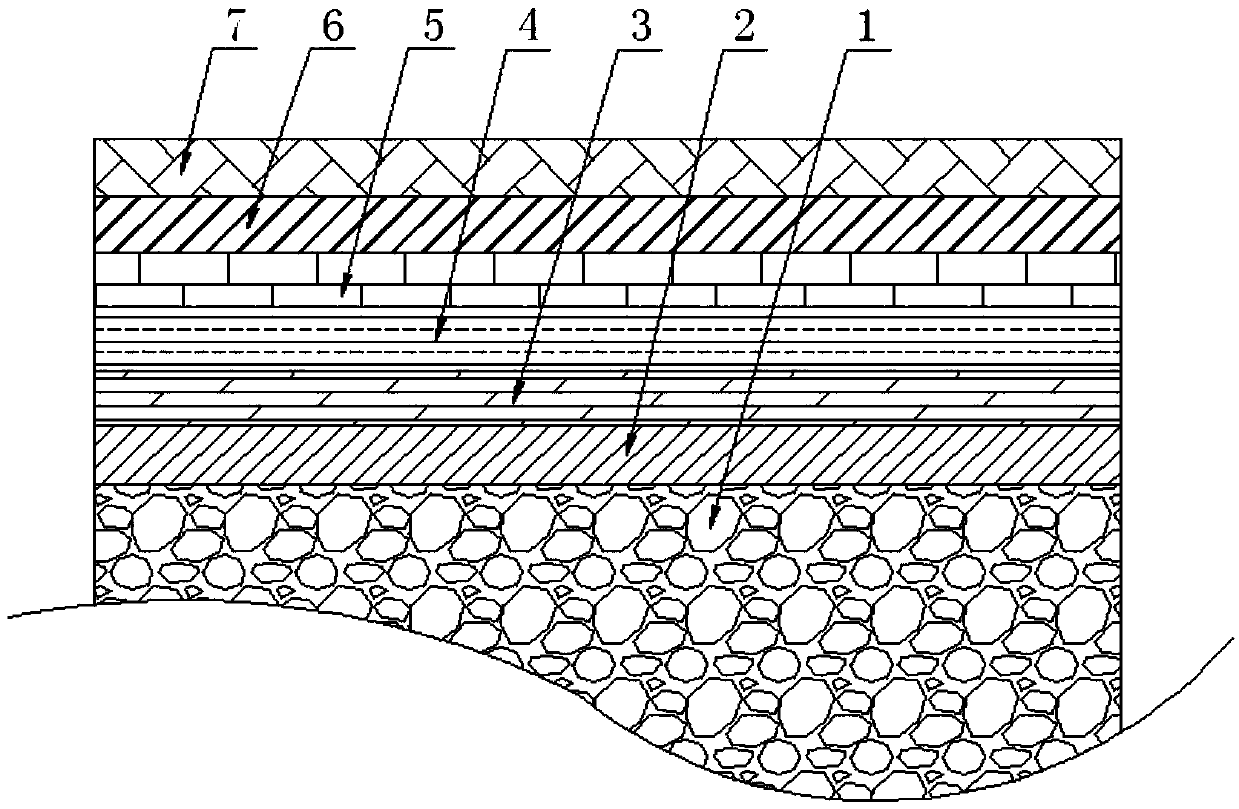

[0042] An ultra-heavy-load anti-static epoxy self-leveling floor, the innovation of which is that it includes concrete base layer 1, epoxy primer layer 2, glass fiber cloth layer 3, epoxy mortar layer 4, Copper foil layer 5, conductive layer 6 and antistatic epoxy self-leveling paint layer 7.

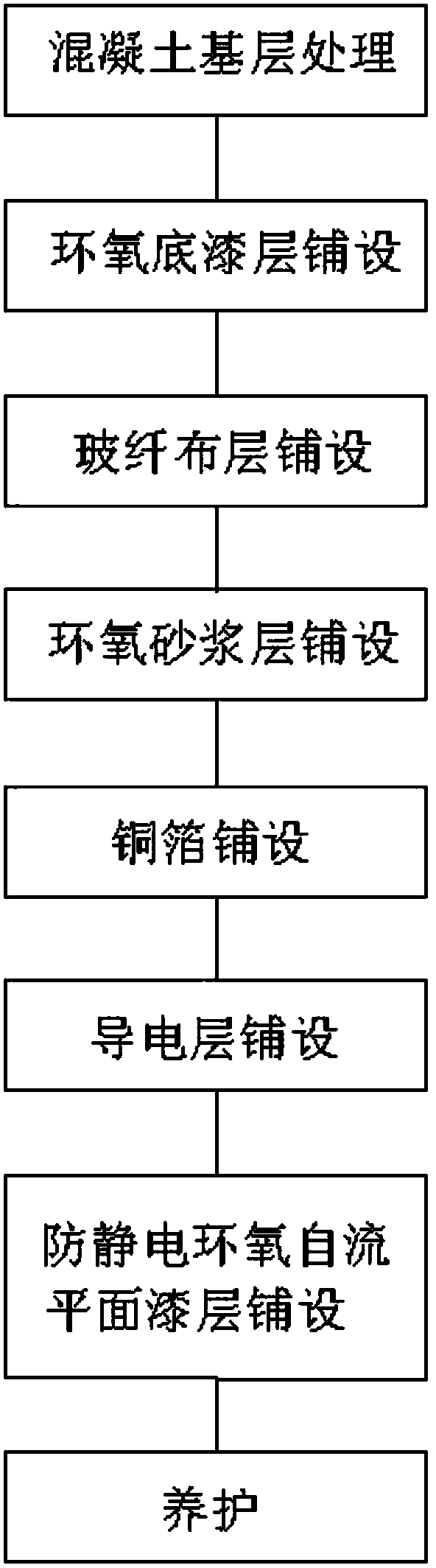

[0043] A construction method for super-heavy-load antistatic epoxy self-leveling ground, the innovation of which is that the steps are as follows:

[0044] 1) Reinforced concrete base laying: Lay steel mesh on the ground, use fine stone concrete to pour, form a reinforced concrete base with a thickness of 30mm, maintain for three weeks and polish the surface to ensure smoothness;

[0045] 2) Epoxy primer layer laying: roll coating with epoxy primer to form an epoxy primer layer with a thickness of 0.1mm;

[0046] 3) Laying of glass fiber cloth layer: lay a layer of glass fiber cloth on the epoxy primer layer coated with epoxy primer, after drying, roll coat epoxy primer on the glass fi...

Embodiment 2

[0061] A super-heavy-load anti-static epoxy self-leveling floor, characterized in that: it includes a concrete base layer, an epoxy primer layer, a glass fiber cloth layer, an epoxy mortar layer, a copper foil layer, and a conductive layer laid sequentially from bottom to top. And anti-static epoxy self-leveling paint layer.

[0062] A construction method for super-heavy-load antistatic epoxy self-leveling ground, the innovation of which is that the steps are as follows:

[0063] 1) Reinforced concrete base laying: Lay steel mesh on the ground, use fine stone concrete to pour, form a reinforced concrete base with a thickness of 40mm, maintain for three weeks and polish the surface to ensure smoothness;

[0064] 2) Epoxy primer layer laying: roll coating with epoxy primer to form an epoxy primer layer with a thickness of 0.2mm;

[0065] 3) Laying of glass fiber cloth layer: lay a layer of glass fiber cloth on the epoxy primer layer coated with epoxy primer, after drying, roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com