Intelligent cleaning and maintaining system and intelligent cleaning and maintaining method of engine

An intelligent cleaning and maintenance system technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems affecting the lubrication, pollution, and labor consumption of important components, achieve thorough and cleaner cleaning, improve cleaning efficiency, and improve cleaning efficiency. better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

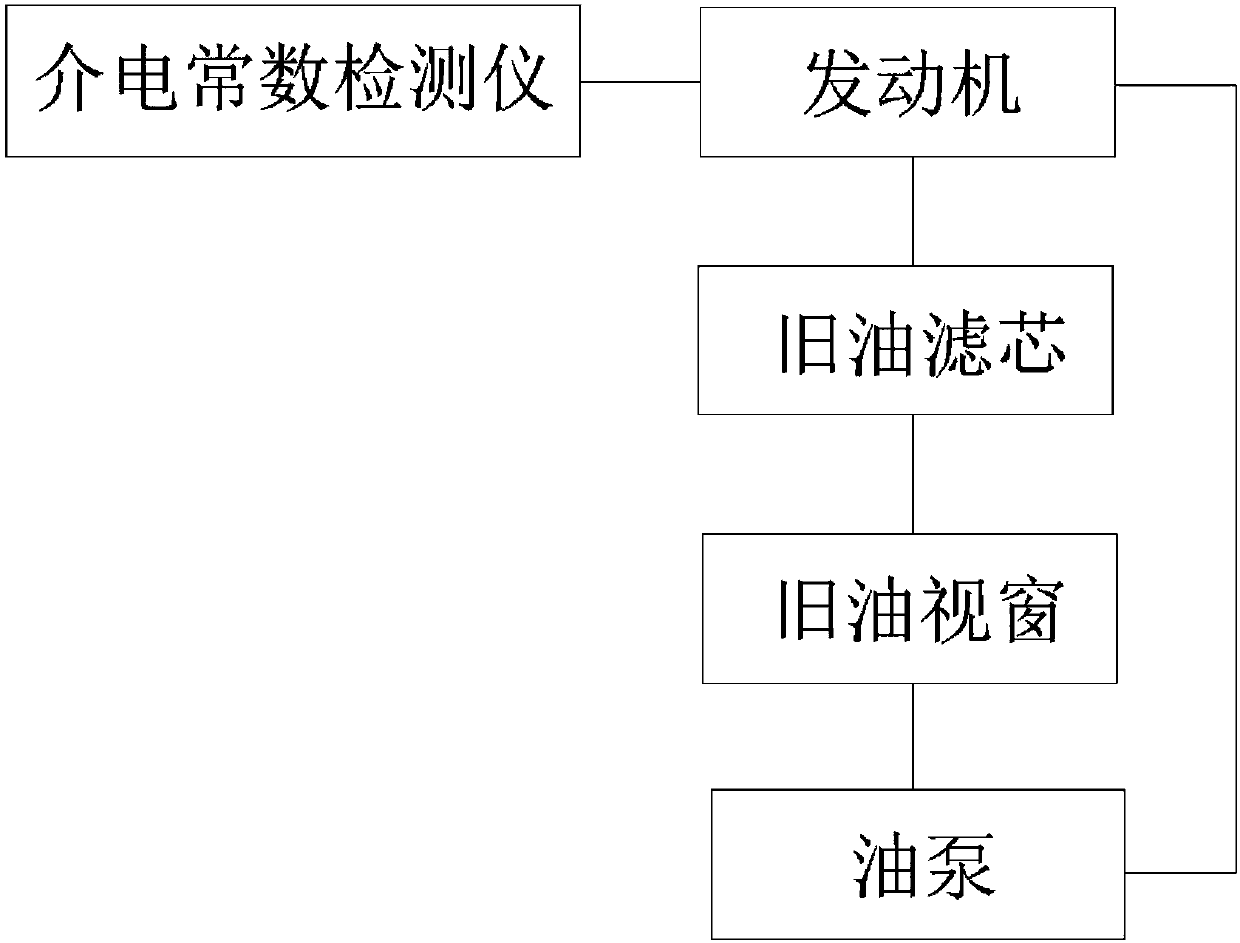

[0047] Such as figure 1 The shown engine intelligent cleaning and maintenance system includes a cleaning pipeline connected to the engine, and the cleaning pipeline is connected to the inside of the engine, wherein the cleaning pipeline is provided with: an old oil filter element used to filter impurities, and can drive The oil pump that flows oil in the cleaning pipeline; the cleaning pipeline is connected with an air intake port that can increase the air pressure. An intelligent engine cleaning and maintenance system is also equipped with a dielectric constant detector that can detect the quality of used oil. The dielectric constant detector can Used to detect the quality of used oil.

[0048] When using the system described in this embodiment to clean, add cleaning oil after the old oil is emptied, and the engine itself is turned on or the power provided by the oil pump makes the cleaning oil flow to the cleaning pipeline after flushing the inside of the engine, and then pa...

Embodiment 2

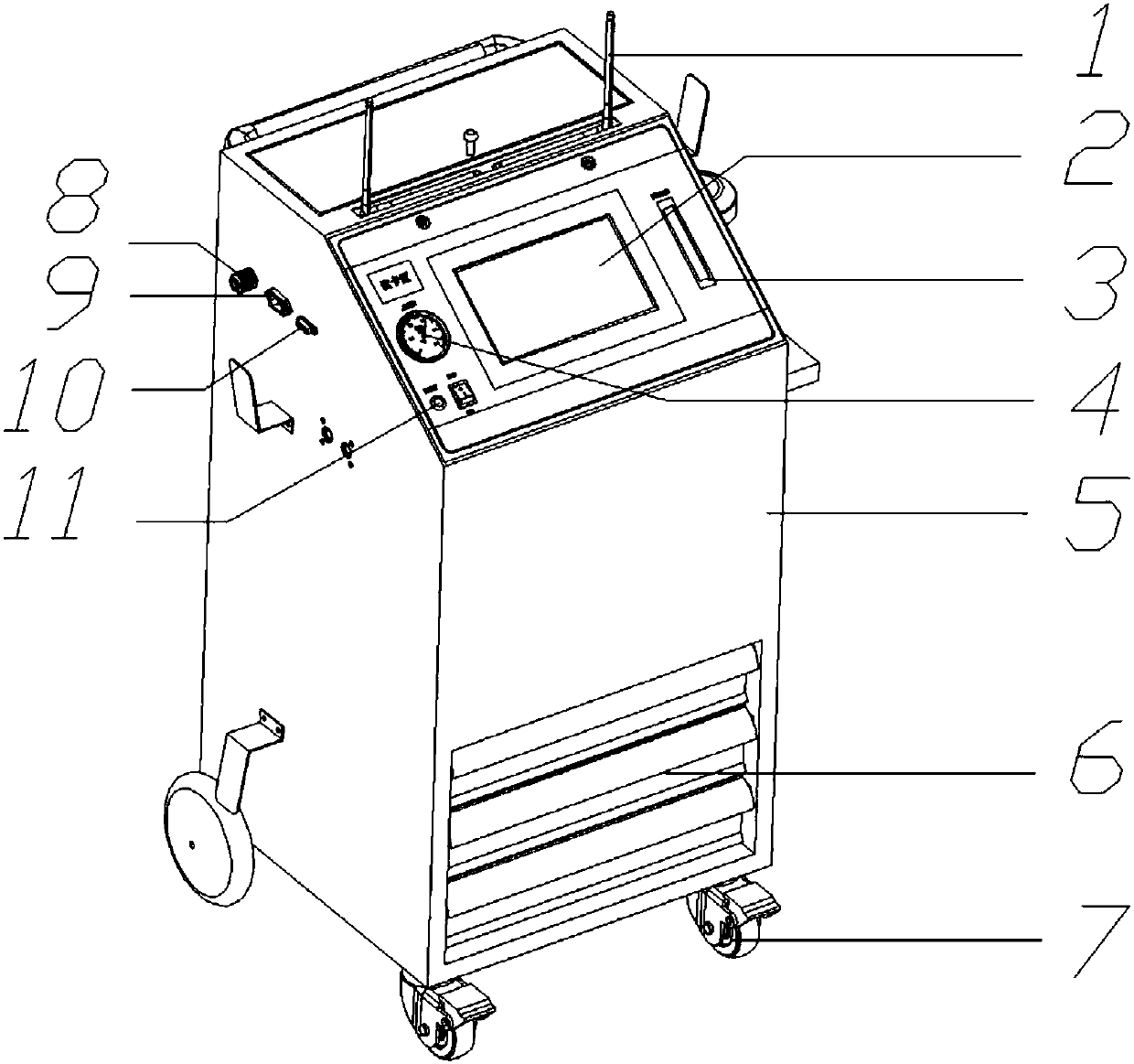

[0055] This embodiment is further described based on the technical solution described in the first embodiment.

[0056] Such as figure 1 As shown, an engine intelligent cleaning and maintenance system also includes a housing 5, the inner pipeline is arranged in the housing 5, and the dielectric constant detector is arranged on the housing 5, and when in use, it is drawn from the engine A certain oil sample is dropped on the dielectric constant detector for detection. The purpose is to detect and judge the service life of the old oil before the cleaning operation starts. If it is still in a usable state, there is no need to replace the lubricating oil. .

[0057] In other embodiments of the present invention, a small amount of in-use oil can be extracted from the inside of the engine by a special tool to test the life of the oil before maintenance is performed. If the indicators of the in-use oil still tend to be normal, it means It can continue to be used. If the test result...

Embodiment 3

[0062] This embodiment is further described based on the technical solutions described in Embodiment 1 and Embodiment 2.

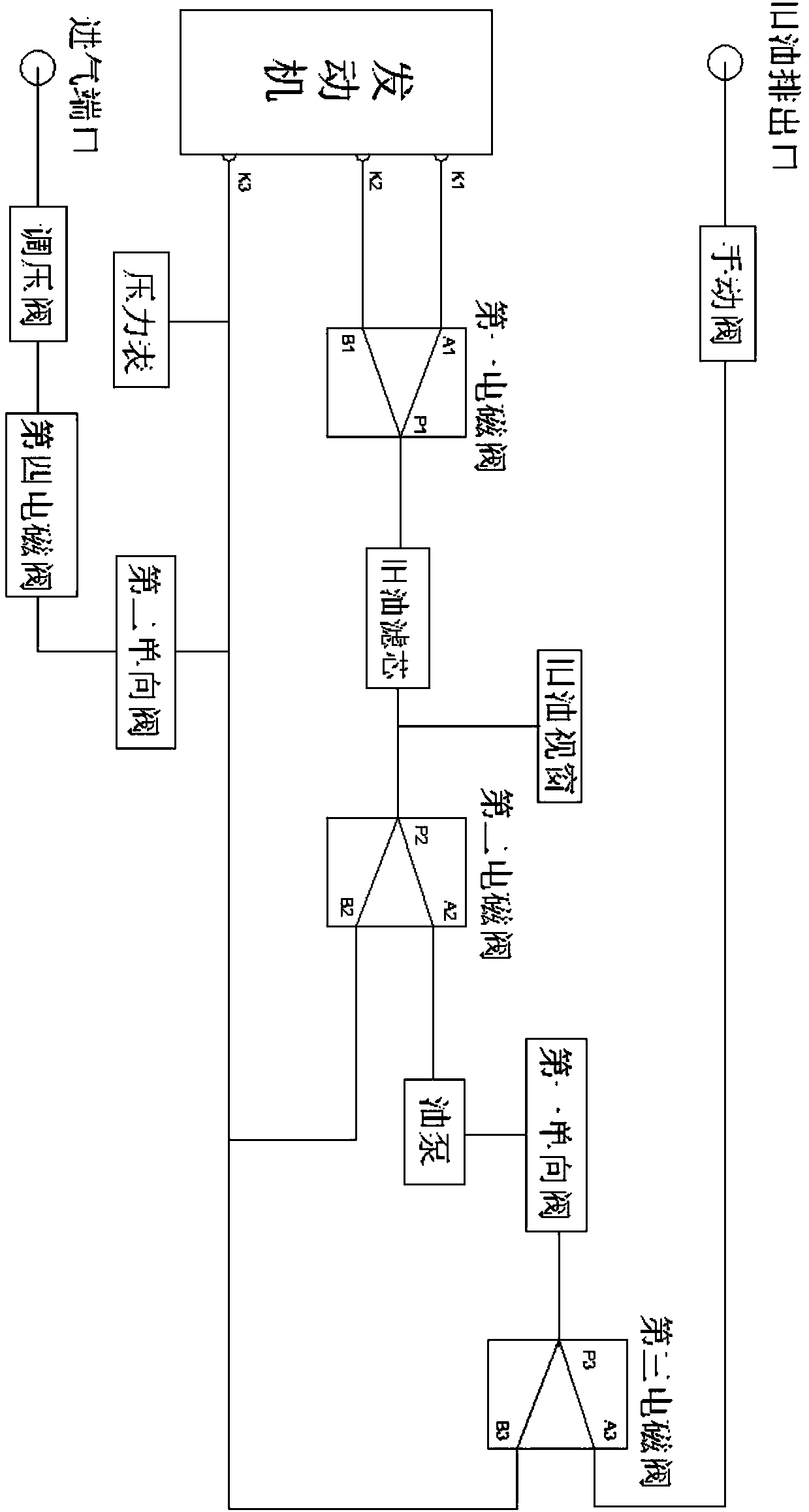

[0063] The cleaning pipeline is provided with a third electromagnetic valve, the oil pump is connected to the K3 interface through the third electromagnetic valve, and the oil pump is also connected to the old oil discharge port through the third electromagnetic valve. After the cleaning is completed, the cleaning oil can be discharged through the old oil discharge port. Further, a manual valve can be arranged on the old oil discharge port, and the cleaning oil can be prevented from leaking when the manual valve is closed.

[0064] The connection mode of the K1, K2, and K3 interfaces can prevent dirt and impurities from clogging the oil filter during the cleaning process, causing the engine to fail to supply oil. The filter is a filter screen for oil pumping. Since the lubricating oil in the engine has been used for a long time, a large amount of impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com