Method and apparatus for controlling oil flow in an internal combustion engine

A technology for internal combustion engines and engines, which is applied in the direction of engine lubrication, engine components, machines/engines, etc. It can solve problems such as increasing the friction of cylinder liners and piston rings, affecting fuel consumption and starting performance, and increasing exhaust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

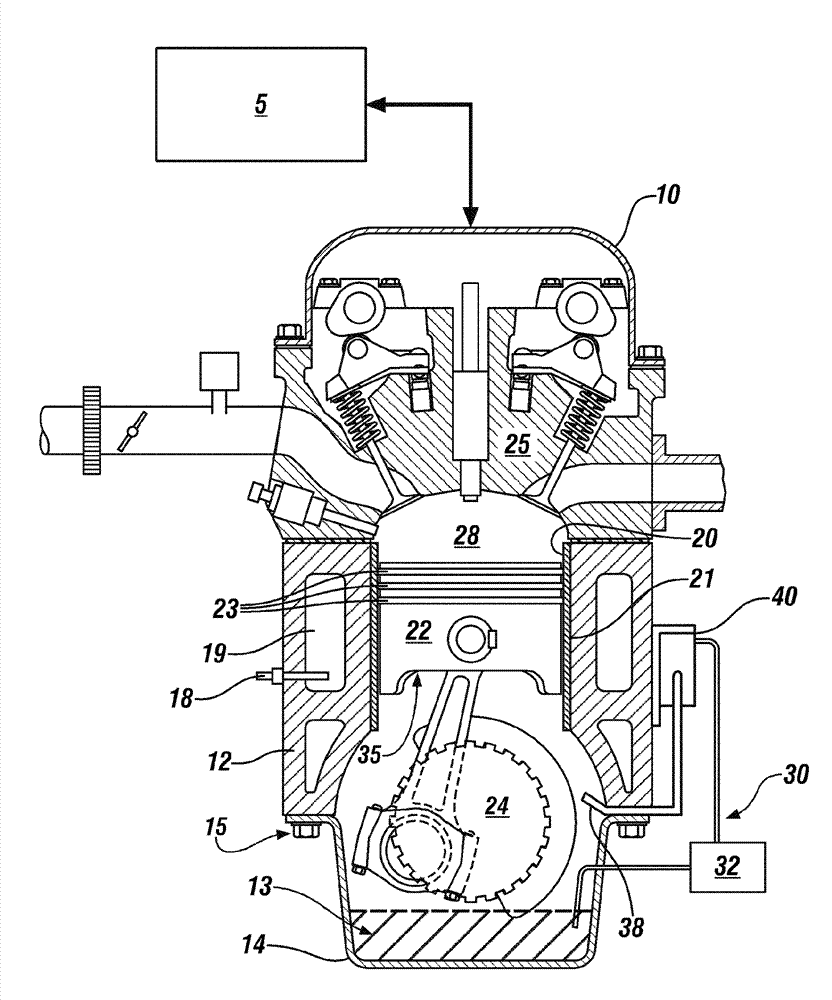

[0034] Referring now to the accompanying drawings, in which the illustrated content is merely to represent some exemplary embodiments and not to limit, figure 1 is a schematic illustration of an internal combustion engine 10 according to the present disclosure. Exemplary engine 10 may be any suitable multi-cylinder internal combustion engine. Engine 10 includes an engine block 12 and a cylinder head 25 . The engine block 12 includes a plurality of cylinders 20 formed therein and a plurality of internally porous coolant passages 19 . The wall portion 21 of each cylinder 20 may comprise a cylinder liner. Each cylinder 20 houses a reciprocating piston 22 connected to a crankshaft 24 . Crankshaft 24 is mechanically coupled to the motor vehicle transmission and driveline to deliver tractive torque thereto in response to an operator torque request. Crankshaft 24 is rotatably connected to lower portion 15 of engine block 12 with main bearings. The oil pan 14 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com