Linear sliding rail having limited travel

A linear slide rail and stroke technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, can solve the problems of increased manufacturing costs, low yield, and falling off of rolling elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

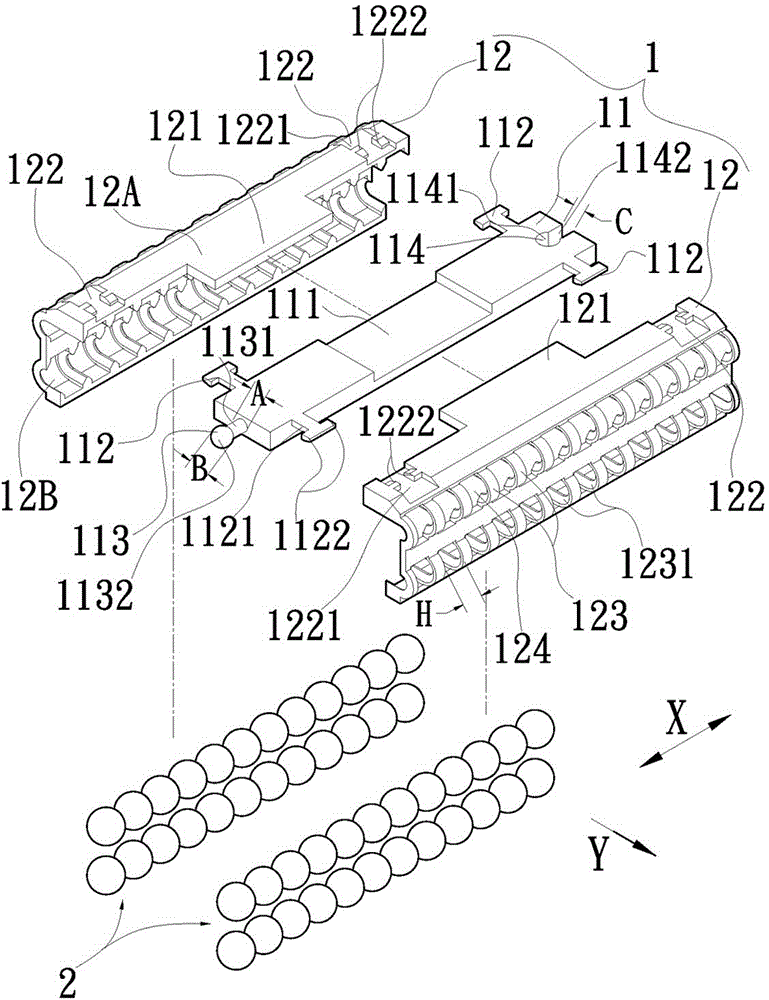

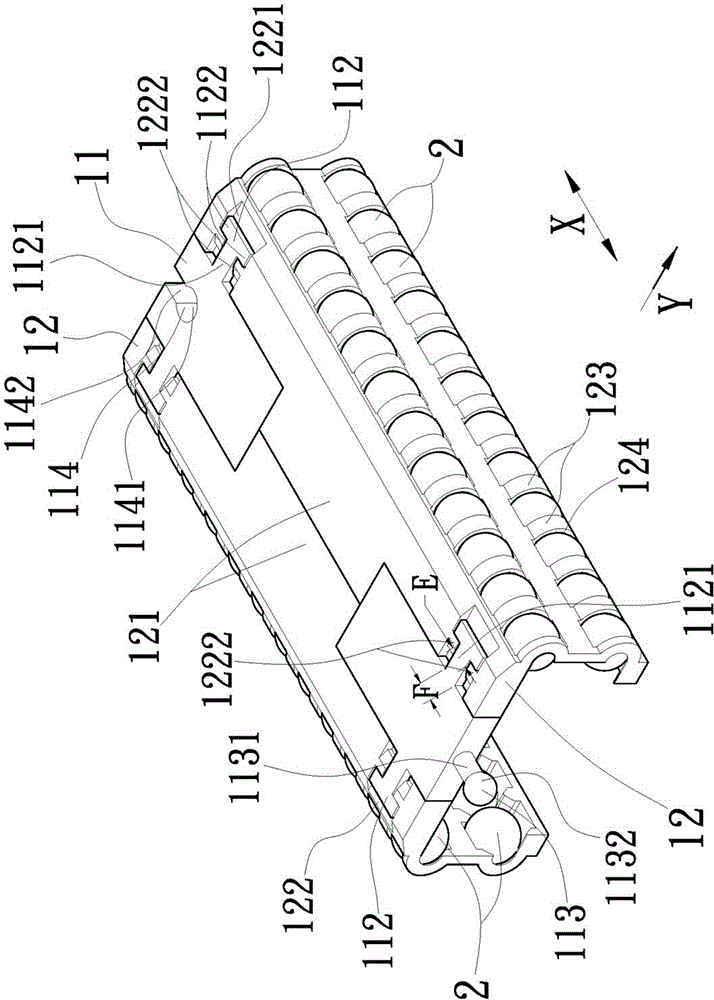

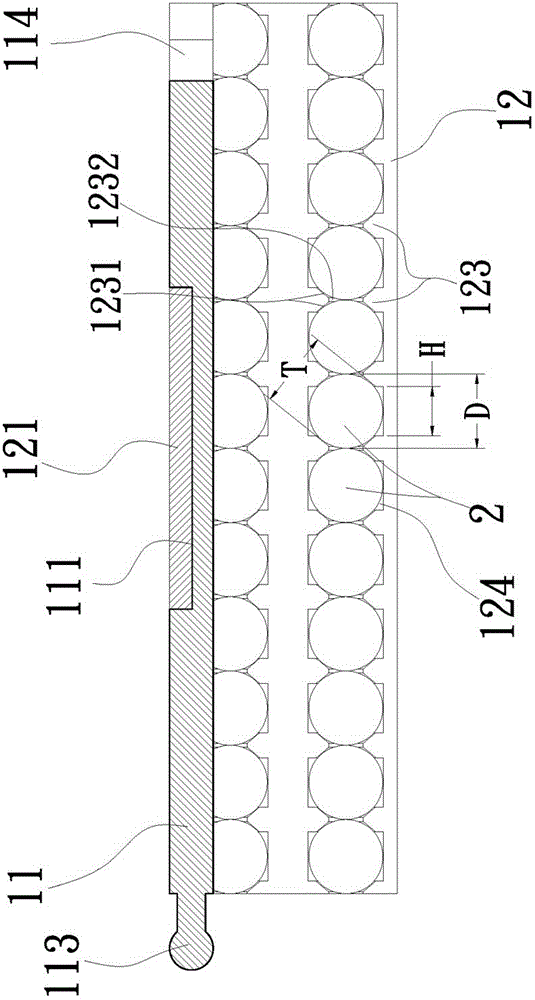

[0067] See Figure 4 to Figure 7 As shown, first, the rolling elements 2 are filled into the accommodating portion 124 of the holding device 1 one by one, and then the holding device 1 with the rolling elements 2 is set on the rail 3, and then the slider 4 is set On the holding device 1, the assembling step of the linear slide rail with limited stroke is completed, and the rolling element 2 is in contact with the load path and can move relative to the load path. When the slider 4 runs for a certain distance, the The running distance of the holding device 1 is half that of the slider 4. Therefore, if the holding device 1 cannot flexibly increase or shorten its length, the length of the holding device 1 required for various industries is different, so Manufacturing has also become another problem, so to solve this problem, please refer to Figure 8 to Figure 10 As shown, in the present invention, by accommodating the second connecting portion 114 of one holding device 1 in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com