Orthodox planet reducer

A planetary reducer and reduction transmission technology, applied in gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of low transmission efficiency, and achieve compact structure, high transmission precision, and large transmission ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation

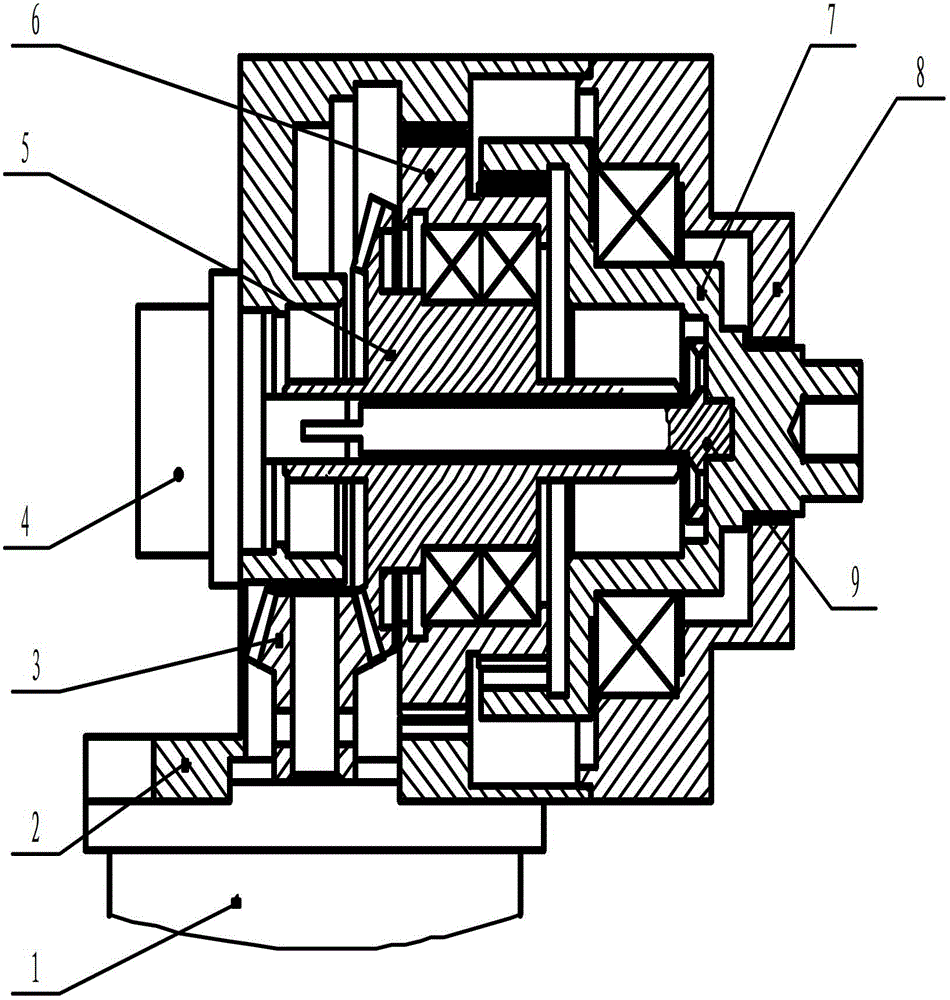

[0011] As shown in the figure, this orthogonal planetary reducer includes a high-speed motor input, a first-stage bevel gear reduction transmission pair, and a second-stage planetary transmission reduction transmission. The first-stage bevel gear transmission includes: a small bevel gear 3 and a large bevel gear 5, the small bevel gear 3 is fastened on the motor shaft through a cylindrical pin, the motor 1 drives the small bevel gear 3 to rotate, and the small bevel gear 3 passes through the positive The alternating mode drives the large bevel gear 5, thereby realizing the first-stage deceleration. The large bevel gear structure has an eccentric structure, and is connected with the planetary gear (duplex gear) 6 through the bearing; the two-stage planetary transmission deceleration includes: through the large bevel gear with eccentric structure The bevel gear 5 drives the double planetary gear 6 to rotate. The rotation of the planetary gear 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com